| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary single-seat double-seal anti-mix valve is a precision control valve used in sanitary systems. It is made of stainless steel to meet the high hygiene requirements of the food, pharmaceutical and other industries, ensuring the purity of the fluid and the safety of the equipment. The stainless steel sanitary single-seat double-seal anti-mix valve is usually installed at the intersection of two different fluids in the pipeline to ensure that the medium can be effectively prevented from mixing during fluid distribution and switching, ensuring the process is accurate, sanitary and safe. Common types of stainless steel sanitary single-seat double-seal anti-mix valves include: normally open anti-mix valve, normally closed anti-mix valve, pneumatic anti-mix valve, manual anti-mix valve, and electric anti-mix valve.

JONENG

8481804090

Stainless Steel Sanitary Welded Single Seat Double Seal MixProof Valve

The stainless steel sanitary single-seat double-seal anti-mix valve is designed to ensure that different media are completely isolated during fluid transmission to avoid cross contamination. This valve uses double sealing technology to effectively prevent fluid mixing in an environment with high hygiene requirements, ensure the independence and purity of each fluid, and avoid quality problems caused by mixing. It is particularly suitable for industries such as pharmaceuticals and food processing. It provides precise and reliable sealing performance during the distribution and switching of multiple fluids, reduces production risks caused by operating errors or equipment failures, and reduces the potential risks of cross contamination. ,

Working Principles

The working principle of the stainless steel sanitary single-seat double-seal anti-mixing valve is based on a double-seal structure, which is designed to ensure that different media are strictly isolated in the pipeline. When the fluid enters the valve, the valve seat and the valve core fit tightly to form the first layer of seal to prevent fluid leakage. A second sealing structure is provided in the valve, usually through a spring or other sealing material, to further ensure that the medium is completely isolated and avoid cross contamination. The valve control system adjusts the position of the valve core as needed to ensure that the fluid does not mix when switching between different pipelines.

The options of the stainless steel sanitary single-seat double-seal anti-mixing valve include:

Drive mode: pneumatic, electric, manual.

Sealing material: EPDM, PTFE, Viton.

Connection method: welding, clamp, flange connection.

Valve body material: 304 stainless steel, 316L stainless steel.

Valve size: customized according to the pipeline diameter.

Valve type: normally open, normally closed.

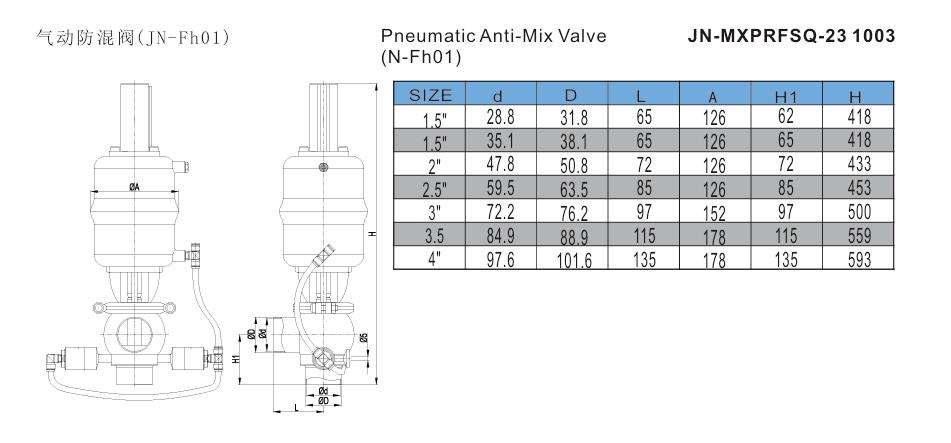

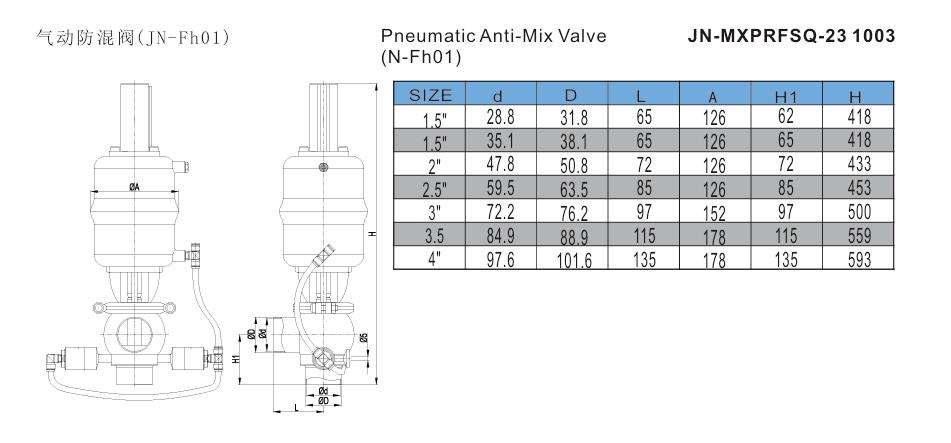

Specification Chart

Size | 1 ½ “ to 4” |

Material | SS304, SS316L |

Max. pressure | 0 to 8 bar pressure |

Max temperature | -20 °C to 150 °C |

Seals | EPDM, NBR, PTFE |

End connections | Welded, threaded, clamped, flanged |

Seals | PTFE, EPDM, NBR |

Features

● The stainless steel sanitary single-seat double-seal anti-mixing valve adopts double-layer sealing technology, and the external seal is separated from the internal seal to ensure that the two media are completely isolated to prevent cross contamination.

● The stainless steel sanitary single-seat double-seal anti-mixing valve has a built-in adjustable sealing pressure device, which allows the user to adjust the sealing pressure according to different operating conditions and optimize the sealing effect of the valve.

● The stainless steel sanitary single-seat double-seal anti-mixing valve is equipped with a built-in leakage detection sensor to monitor the leakage between the double sealing layers in real time and provide timely feedback to the control system.

● The inner and outer surfaces of the stainless steel sanitary single-seat double-seal anti-mixing valve are coated with a special coating that is resistant to high temperature and chemical corrosion, and can be used for a long time in harsh environments such as strong acids and alkalis.

● The internal structure of the stainless steel sanitary single-seat double-seal anti-mixing valve adopts a modular design. Users can replace and upgrade various functional modules (such as sealing, drive, etc.) according to different needs.

● The stainless steel sanitary single-seat double-seal anti-mixing valve is equipped with a dual adjustment system, which can not only adjust the flow of the fluid, but also accurately control the system pressure to ensure the stable operation of the valve and pipeline.

Application

Stainless steel sanitary single-seat double-seal anti-mixing valve is widely used in the following industries: Food processing: prevent cross-contamination between different food raw materials. Pharmaceutical industry: ensure the purity and safety of fluids in the production process of drugs. Beverage industry: isolate different beverage fluids to avoid product mixing. Cosmetics industry: Ensure the isolation of various ingredients during the cosmetics production process. Chemical industry: Prevent chemical mixing to ensure product quality and safety. Water treatment industry: Prevent different treatment media in the water flow from contaminating each other. Biological products industry: Isolate biological liquids to ensure purity and no pollution.

Working Principles

The working principle of the stainless steel sanitary single-seat double-seal anti-mixing valve is based on a double-seal structure, which is designed to ensure that different media are strictly isolated in the pipeline. When the fluid enters the valve, the valve seat and the valve core fit tightly to form the first layer of seal to prevent fluid leakage. A second sealing structure is provided in the valve, usually through a spring or other sealing material, to further ensure that the medium is completely isolated and avoid cross contamination. The valve control system adjusts the position of the valve core as needed to ensure that the fluid does not mix when switching between different pipelines.

The options of the stainless steel sanitary single-seat double-seal anti-mixing valve include:

Drive mode: pneumatic, electric, manual.

Sealing material: EPDM, PTFE, Viton.

Connection method: welding, clamp, flange connection.

Valve body material: 304 stainless steel, 316L stainless steel.

Valve size: customized according to the pipeline diameter.

Valve type: normally open, normally closed.

Specification Chart

Size | 1 ½ “ to 4” |

Material | SS304, SS316L |

Max. pressure | 0 to 8 bar pressure |

Max temperature | -20 °C to 150 °C |

Seals | EPDM, NBR, PTFE |

End connections | Welded, threaded, clamped, flanged |

Seals | PTFE, EPDM, NBR |

Features

● The stainless steel sanitary single-seat double-seal anti-mixing valve adopts double-layer sealing technology, and the external seal is separated from the internal seal to ensure that the two media are completely isolated to prevent cross contamination.

● The stainless steel sanitary single-seat double-seal anti-mixing valve has a built-in adjustable sealing pressure device, which allows the user to adjust the sealing pressure according to different operating conditions and optimize the sealing effect of the valve.

● The stainless steel sanitary single-seat double-seal anti-mixing valve is equipped with a built-in leakage detection sensor to monitor the leakage between the double sealing layers in real time and provide timely feedback to the control system.

● The inner and outer surfaces of the stainless steel sanitary single-seat double-seal anti-mixing valve are coated with a special coating that is resistant to high temperature and chemical corrosion, and can be used for a long time in harsh environments such as strong acids and alkalis.

● The internal structure of the stainless steel sanitary single-seat double-seal anti-mixing valve adopts a modular design. Users can replace and upgrade various functional modules (such as sealing, drive, etc.) according to different needs.

● The stainless steel sanitary single-seat double-seal anti-mixing valve is equipped with a dual adjustment system, which can not only adjust the flow of the fluid, but also accurately control the system pressure to ensure the stable operation of the valve and pipeline.

Application

Stainless steel sanitary single-seat double-seal anti-mixing valve is widely used in the following industries: Food processing: prevent cross-contamination between different food raw materials. Pharmaceutical industry: ensure the purity and safety of fluids in the production process of drugs. Beverage industry: isolate different beverage fluids to avoid product mixing. Cosmetics industry: Ensure the isolation of various ingredients during the cosmetics production process. Chemical industry: Prevent chemical mixing to ensure product quality and safety. Water treatment industry: Prevent different treatment media in the water flow from contaminating each other. Biological products industry: Isolate biological liquids to ensure purity and no pollution.