Stainless Steel Single Seat Mixproof Valve for Food Processing

This are designed for controlled and contamination free flow of the liquid for the different fluid in the industrial processes. These are composed of valve body, seals, valve discs, actuator, CIP components and control systems. There are leakage detection holes that helps in visually inspecting the fluid without dissembling the valve. The CIP system helps in easy maintenance.

Working Principles

This valve is normally a closed valve operated remotely through the compressed air. For separation of the liquid there are 2 individual plug seals. The space in between this seals forms a leakage chamber where the product fall during the rare case of the leakage.

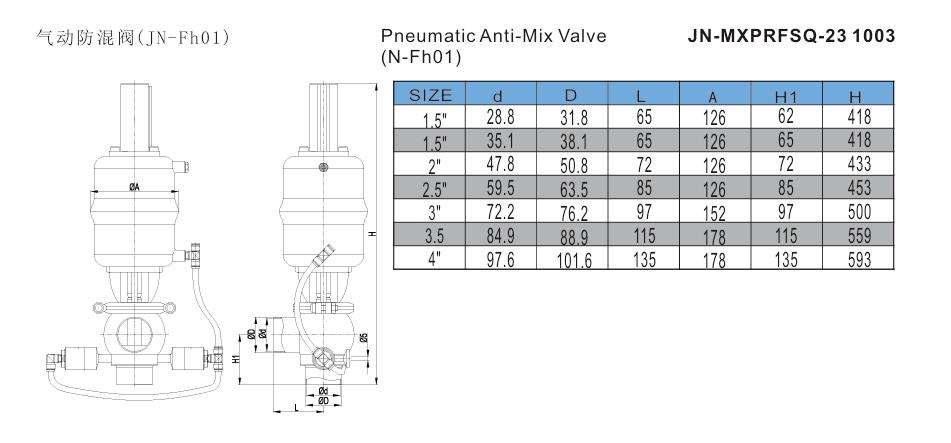

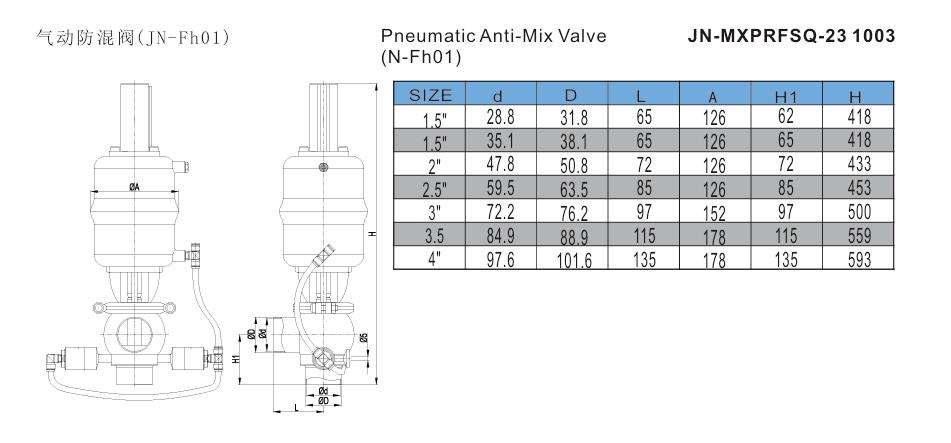

Stainless Steel Mixproof Valve Specification Chart

Size | 1 ½ “ to 4” |

Material | SS304, SS316L |

Max. pressure | 0 to 8 bar pressure |

Max temperature | -20 °C to 150 °C |

Seals | EPDM, NBR, PTFE |

End connections | Welded, threaded, clamped, flanged |

Seals | PTFE, EPDM, NBR |

Features

●Cost effective, easy to maintain

●Safe and high product quality

●Cross contamination prevention

● Efficient and versatile

Application

These valves are used in food and beverage industries, pharmaceuticals, chemical, cosmetic and personal care, paper industry and other where there is need of preventing the cross contamination of 2 fluids

Working Principles

This valve is normally a closed valve operated remotely through the compressed air. For separation of the liquid there are 2 individual plug seals. The space in between this seals forms a leakage chamber where the product fall during the rare case of the leakage.

Feature and Specification

Stainless Steel Mixproof Valve Specification Chart

Size | 1 ½ “ to 4” |

Material | SS304, SS316L |

Max. pressure | 0 to 8 bar pressure |

Max temperature | -20 °C to 150 °C |

Seals | EPDM, NBR, PTFE |

End connections | Welded, threaded, clamped, flanged |

Seals | PTFE, EPDM, NBR |

Features

●Cost effective, easy to maintain

●Safe and high product quality

●Cross contamination prevention

● Efficient and versatile

Application

These valves are used in food and beverage industries, pharmaceuticals, chemical, cosmetic and personal care, paper industry and other where there is need of preventing the cross contamination of 2 fluids

Stainless Steel Single Seat Mixproof Valve for Food Processing

This are designed for controlled and contamination free flow of the liquid for the different fluid in the industrial processes. These are composed of valve body, seals, valve discs, actuator, CIP components and control systems. There are leakage detection holes that helps in visually inspecting the fluid without dissembling the valve. The CIP system helps in easy maintenance.

Working Principles

This valve is normally a closed valve operated remotely through the compressed air. For separation of the liquid there are 2 individual plug seals. The space in between this seals forms a leakage chamber where the product fall during the rare case of the leakage.

Stainless Steel Mixproof Valve Specification Chart

Size | 1 ½ “ to 4” |

Material | SS304, SS316L |

Max. pressure | 0 to 8 bar pressure |

Max temperature | -20 °C to 150 °C |

Seals | EPDM, NBR, PTFE |

End connections | Welded, threaded, clamped, flanged |

Seals | PTFE, EPDM, NBR |

Features

●Cost effective, easy to maintain

●Safe and high product quality

●Cross contamination prevention

● Efficient and versatile

Application

These valves are used in food and beverage industries, pharmaceuticals, chemical, cosmetic and personal care, paper industry and other where there is need of preventing the cross contamination of 2 fluids

Working Principles

This valve is normally a closed valve operated remotely through the compressed air. For separation of the liquid there are 2 individual plug seals. The space in between this seals forms a leakage chamber where the product fall during the rare case of the leakage.

Feature and Specification

Stainless Steel Mixproof Valve Specification Chart

Size | 1 ½ “ to 4” |

Material | SS304, SS316L |

Max. pressure | 0 to 8 bar pressure |

Max temperature | -20 °C to 150 °C |

Seals | EPDM, NBR, PTFE |

End connections | Welded, threaded, clamped, flanged |

Seals | PTFE, EPDM, NBR |

Features

●Cost effective, easy to maintain

●Safe and high product quality

●Cross contamination prevention

● Efficient and versatile

Application

These valves are used in food and beverage industries, pharmaceuticals, chemical, cosmetic and personal care, paper industry and other where there is need of preventing the cross contamination of 2 fluids