| Availability: | |

|---|---|

| Quantity: | |

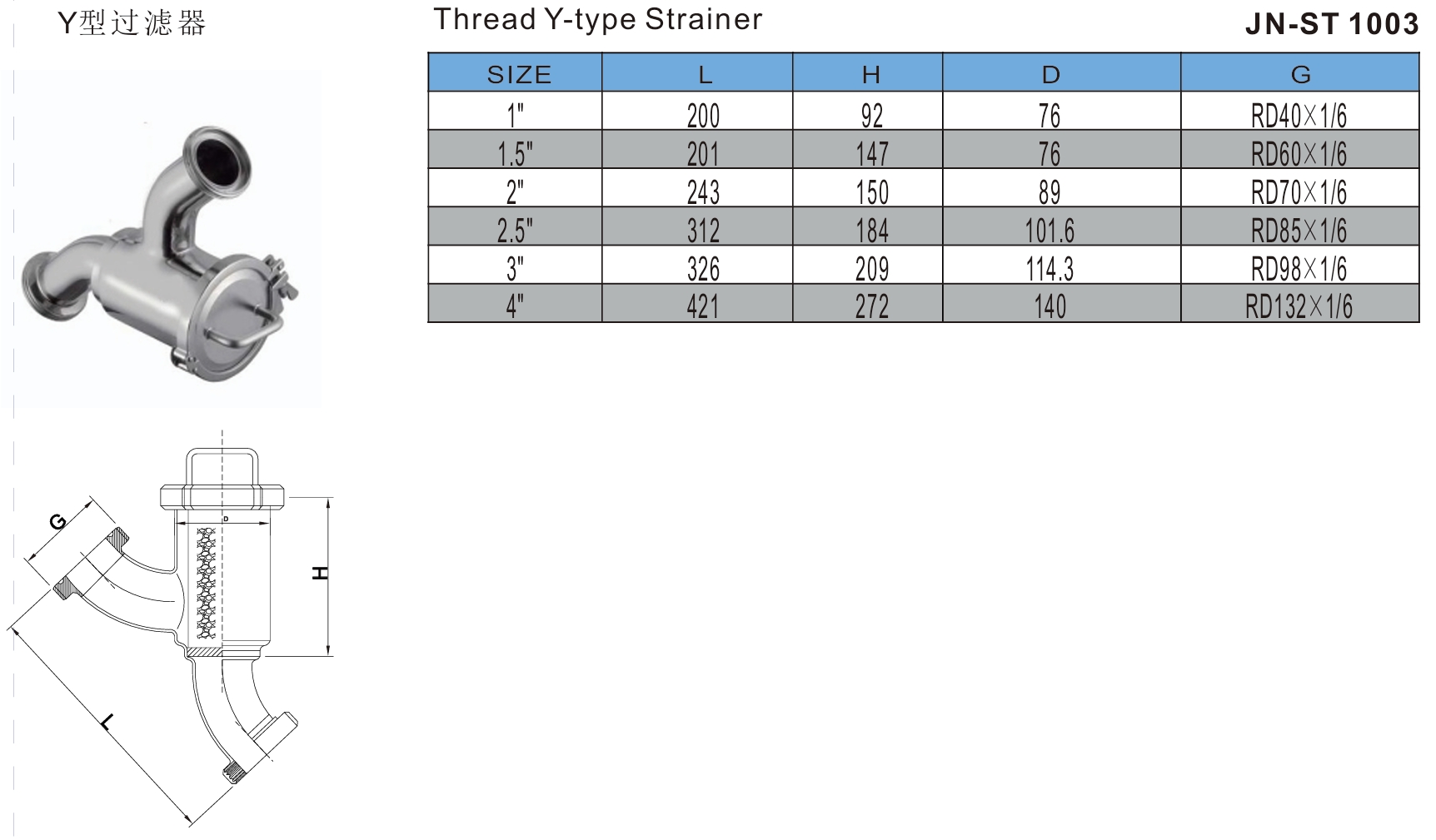

The stainless steel sanitary Y-thread filter is a filtering device designed for pipeline systems with high hygienic requirements. In addition to conventional liquid filtration, it is also often used to ensure that chemical, gas, steam and other fluids in the conveying system remain pure and avoid the influence of tiny impurities on precision instruments. The stainless steel sanitary Y-thread filter is usually installed at the inlet or outlet of the pipeline system, especially in the fluid pipeline that requires high hygienic standards. It is used to filter the key parts such as the front of the pump, the front of the valve or the water inlet of the heat exchanger in the pipeline. Common types of stainless steel sanitary Y-thread filters include: coarse filtration type, fine filtration type, automatic backwash type, manual cleaning type, stainless steel mesh filtration type, and liquid-specific type.

JN-STZT-23 1005

JONENG

8421219990

Stainless Steel Threaded Y-Type Bag Filter Cartridge for Pressure Gauge

The stainless steel sanitary Y-thread filter is designed not only to filter impurities, but also to meet the needs of refined filtration under high hygienic standards. It can effectively prevent cross-contamination caused by tiny particles in the fluid, especially in the pharmaceutical and biotechnology fields, to protect the cleanliness of every link in the drug production process. In addition, its compact design makes it suitable for small spaces, and it has a quick disassembly function, which is easy to clean and maintain, and provides reliable performance guarantee under demanding working conditions.

Working Principles

The working principle of the stainless steel sanitary Y-type threaded filter is to guide the fluid into the filter through its Y-shaped pipe structure. When the fluid passes through the built-in filter medium (such as stainless steel mesh or filter element), the solid impurities are intercepted in the filter mesh, and the clean fluid flows out smoothly through the filter. When enough impurities accumulate in the filter, the accumulated dirt can be discharged through the drain port or backwashing function. Using a stainless steel sanitary Y-type threaded filter can prevent impurities from accumulating in the pipeline, ensure smooth flow of fluid, reduce system pressure loss, and improve fluid flow efficiency.

The options of the stainless steel sanitary Y-type threaded filter include:

Filtration accuracy: filter elements or meshes with different pore sizes can be selected to meet the filtering needs of different particle sizes.

Cleaning method: manual cleaning or automatic backwashing to meet different maintenance needs.

Material: 304 or 316L stainless steel can be selected for different corrosion resistance requirements.

Interface type: The thread interface size (such as G1/2, G1, etc.) can be selected according to the pipeline specifications.

Filter element material: stainless steel mesh, polyester, nylon, etc., select the appropriate material according to the medium.

Sewage discharge method: manual sewage outlet or automatic sewage discharge function, easy to clean up the accumulated sewage.

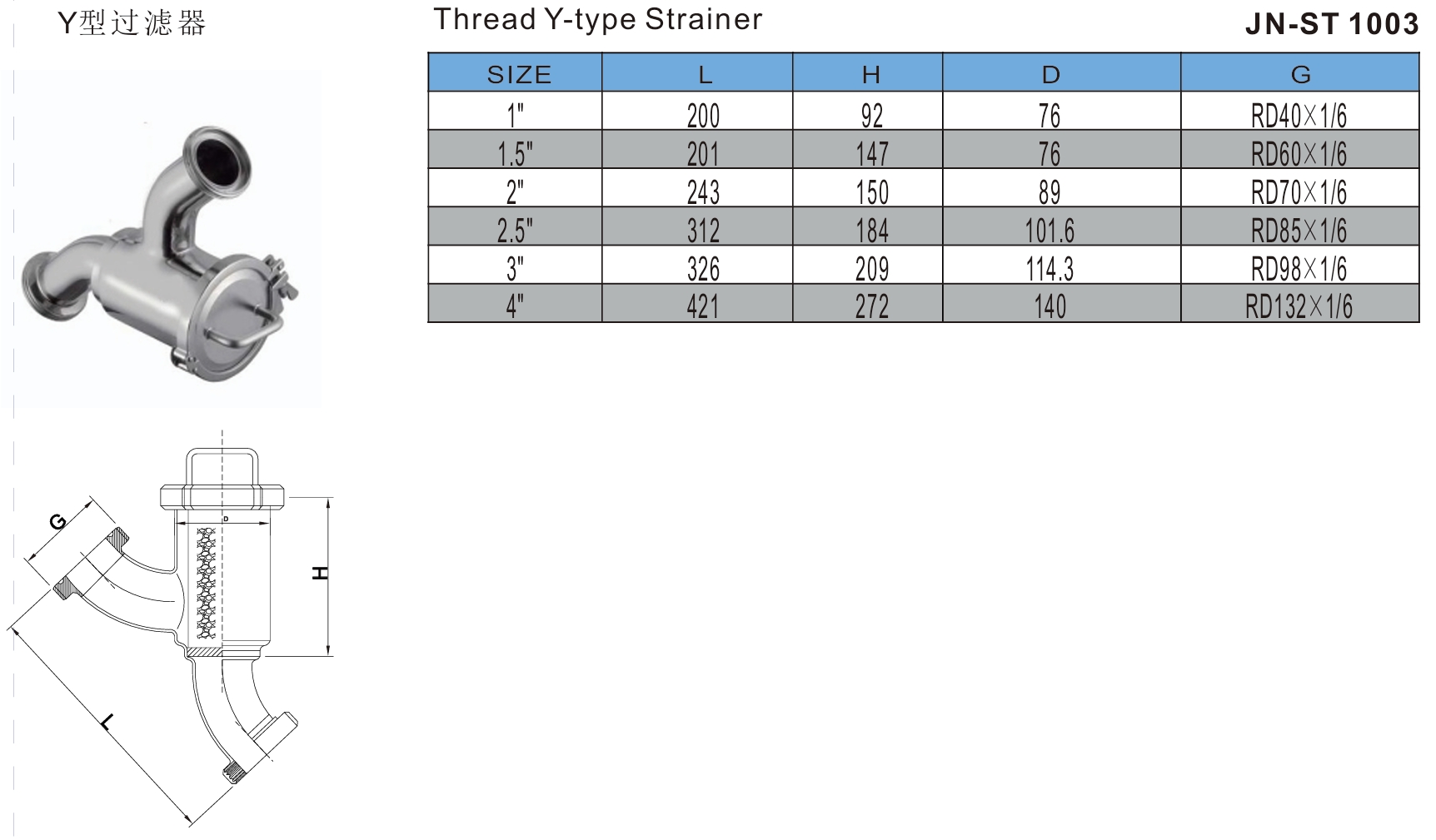

Specification Chart

Size | 1”-4” |

Material | AISI 316, AISI 304 |

Connection | Clamped, Welded, Threaded |

Gasket | Silicone, EPDM, Viton, PTFE |

Standard | 3A, DIN, SMS, ISO |

Mesh size | From 0.5mm to 2.0mm |

Screen | From 30 mesh to 300 mesh |

Internal Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

| External Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

Features

● The internal structure of the stainless steel sanitary Y-type threaded filter has no dead angles, avoiding the accumulation of impurities and ensuring that the filter is always in a clean state.

● The surface of the stainless steel sanitary Y-type threaded filter is mirror-polished to reduce the surface roughness for bacterial growth.

● The stainless steel sanitary Y-type threaded filter is compact in design, occupies little space, adapts to narrow installation spaces, and is easy to install and maintain in limited spaces.

● The stainless steel sanitary Y-type threaded filter adopts internal and external seamless welding technology to avoid the risk of microbial growth at the welding point and ensure the sealing and corrosion resistance of the filter.

● The stainless steel sanitary Y-type threaded filter adopts a quick thread interface design, allowing users to quickly disassemble and clean without tools, which is suitable for high-frequency sanitary inspections and cleaning.

● The stainless steel sanitary Y-type threaded filter is designed with a multi-layer filter mesh structure, and different mesh sizes can be selected according to different application requirements.

Application

The options for stainless steel sanitary Y-type threaded filters include: Water treatment industry: filter impurities in water to ensure clean water sources. Food processing: prevent impurities from contaminating raw materials and products and improve hygiene standards. Chemical industry: filter chemicals to avoid pipe blockage or equipment damage. Pharmaceutical industry: ensure the cleanliness of production fluids and prevent cross contamination. Oil and gas: protect pipelines and pump equipment to prevent particles from damaging the system. Environmental protection industry: filter solid particles in wastewater to reduce pollution.

Working Principles

The working principle of the stainless steel sanitary Y-type threaded filter is to guide the fluid into the filter through its Y-shaped pipe structure. When the fluid passes through the built-in filter medium (such as stainless steel mesh or filter element), the solid impurities are intercepted in the filter mesh, and the clean fluid flows out smoothly through the filter. When enough impurities accumulate in the filter, the accumulated dirt can be discharged through the drain port or backwashing function. Using a stainless steel sanitary Y-type threaded filter can prevent impurities from accumulating in the pipeline, ensure smooth flow of fluid, reduce system pressure loss, and improve fluid flow efficiency.

The options of the stainless steel sanitary Y-type threaded filter include:

Filtration accuracy: filter elements or meshes with different pore sizes can be selected to meet the filtering needs of different particle sizes.

Cleaning method: manual cleaning or automatic backwashing to meet different maintenance needs.

Material: 304 or 316L stainless steel can be selected for different corrosion resistance requirements.

Interface type: The thread interface size (such as G1/2, G1, etc.) can be selected according to the pipeline specifications.

Filter element material: stainless steel mesh, polyester, nylon, etc., select the appropriate material according to the medium.

Sewage discharge method: manual sewage outlet or automatic sewage discharge function, easy to clean up the accumulated sewage.

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● The internal structure of the stainless steel sanitary Y-type threaded filter has no dead angles, avoiding the accumulation of impurities and ensuring that the filter is always in a clean state.

● The surface of the stainless steel sanitary Y-type threaded filter is mirror-polished to reduce the surface roughness for bacterial growth.

● The stainless steel sanitary Y-type threaded filter is compact in design, occupies little space, adapts to narrow installation spaces, and is easy to install and maintain in limited spaces.

● The stainless steel sanitary Y-type threaded filter adopts internal and external seamless welding technology to avoid the risk of microbial growth at the welding point and ensure the sealing and corrosion resistance of the filter.

● The stainless steel sanitary Y-type threaded filter adopts a quick thread interface design, allowing users to quickly disassemble and clean without tools, which is suitable for high-frequency sanitary inspections and cleaning.

● The stainless steel sanitary Y-type threaded filter is designed with a multi-layer filter mesh structure, and different mesh sizes can be selected according to different application requirements.

Application

The options for stainless steel sanitary Y-type threaded filters include: Water treatment industry: filter impurities in water to ensure clean water sources. Food processing: prevent impurities from contaminating raw materials and products and improve hygiene standards. Chemical industry: filter chemicals to avoid pipe blockage or equipment damage. Pharmaceutical industry: ensure the cleanliness of production fluids and prevent cross contamination. Oil and gas: protect pipelines and pump equipment to prevent particles from damaging the system. Environmental protection industry: filter solid particles in wastewater to reduce pollution.