| Availability: | |

|---|---|

| Quantity: | |

A stainless-steel duplex strainer plays a crucial role in protecting downstream equipment, such as pumps, valves, and other process components, by preventing solid particles from entering and causing damage or disruption. SS duplex strainer is commonly installed in pipelines where the removal of contaminants from liquids is essential for the efficient and reliable operation of industrial processes.

JONENG

8421219990

Stainless Steel Well Screen Duplex Twins Filter for Milk, Wine, Drinks, Vinegar

A stainless-steel duplex strainer plays a crucial role in protecting downstream equipment, such as pumps, valves, and other process components, by preventing solid particles from entering and causing damage or disruption. SS duplex strainer is commonly installed in pipelines where the removal of contaminants from liquids is essential for the efficient and reliable operation of industrial processes.

Working Principles

The working principle of a stainless steel duplex strainer involves the filtration of solid particles from liquids in an industrial pipeline while ensuring continuous operation.

This alternating operation ensures that there is minimal downtime for maintenance, as one basket can be cleaned while the other remains in operation. The duplex design allows for continuous filtration, making it suitable for applications where uninterrupted flow is essential for process efficiency.

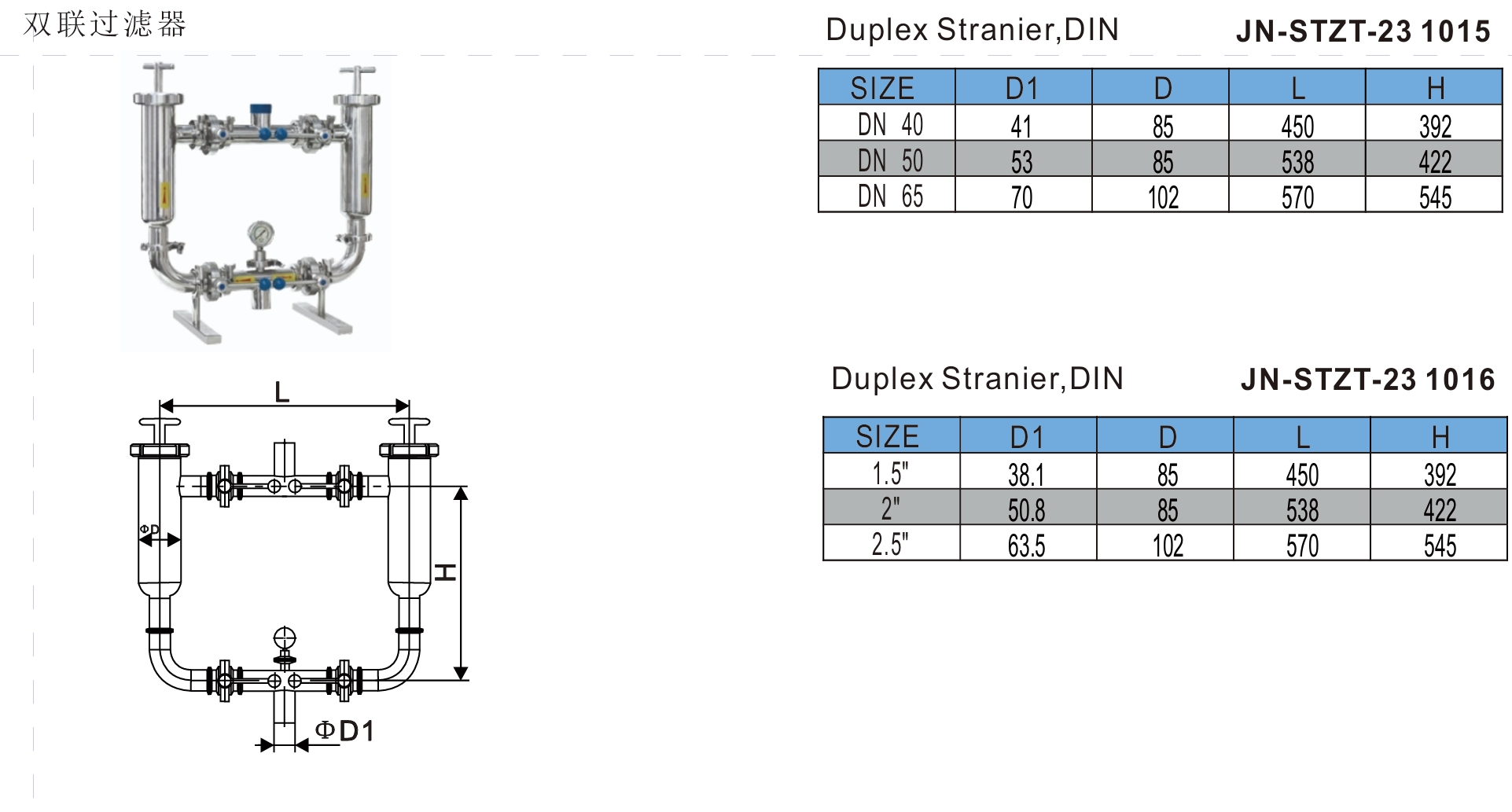

Stainless Steel Duplex Filter Specification Chart

Material | SS304, SS316L |

Size | 1”-4” |

Inner surface finish | Ra0.5 |

External surface finish | Ra 0.8 |

Standard | SMS, 3A, BPE, ISO |

Seals | EPDM, PTFE, Silicone |

Max pressure | 10 bar |

Max temperature | -10℃ to 120℃ |

| End connection | Threaded, welded, clamped |

| Screen | 30-300 meshes |

| Screen hole | 0.5mm-2mm |

Features

●Continuous operation: The duplex design, with two separate strainer baskets, allows for continuous filtration even during maintenance. This minimizes downtime and ensures uninterrupted flow in critical processes.

●High corrosion resistance

●Enhanced strength

●Durability

●Ease of maintenance

●Efficient filtration: The perforations or mesh in the strainer baskets effectively capture solid particles while allowing the liquid to pass through. This efficient filtration helps protect downstream equipment from damage and ensures the quality and integrity of the processed fluid.

●Pressure monitoring: Many duplex strainers are equipped with pressure gauges or differential pressure ports to monitor the pressure drop across the strainer.

Application

The SS duplex strainer are mostly used in food, beverage, dairy, pharmaceuticals, chemical, and any other food processing industries.

Working Principles

This works on a fairly simple principle, it filters and eliminates the pollutants by straining them through the mesh from liquid or gas while passing through the pipeline or tubing.

Feature and Specification

Stainless Steel Ln Line Filter Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

●Equipment protection, contaminant removal

●Product quality, improved system efficiency

●Customizability, health and safety

●Small pressure loss

●Good filtration

●Sealing ability

●Each cleaning

Application

This has various application in industries like water filtration and treatment plant, pharmaceutical and biotech, laboratory and research, chemical processing and others.