| Availability: | |

|---|---|

| Quantity: | |

JONENG

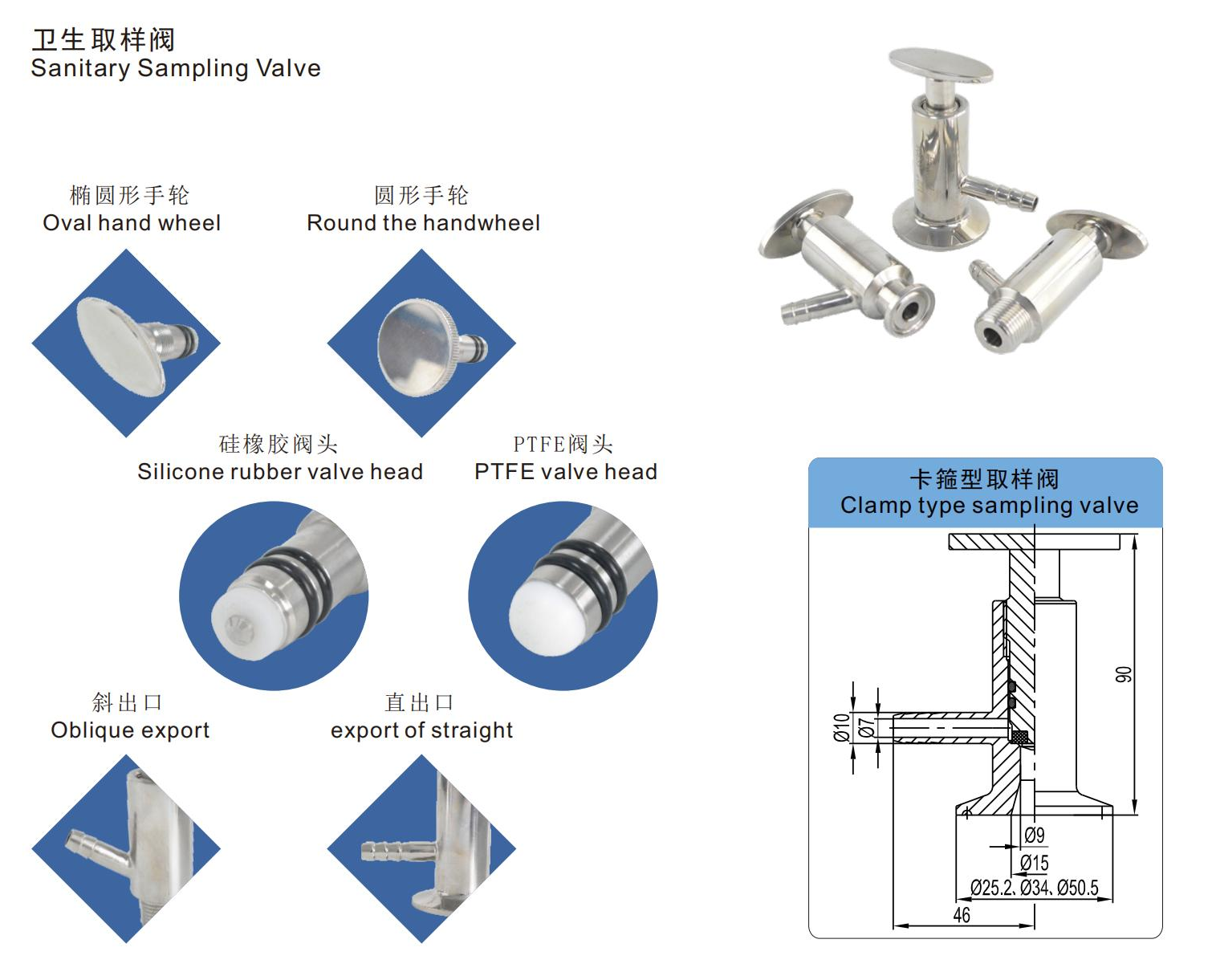

Stainless steel food-grade beer sampling valve

Working Principles

The working principle of the food-grade stainless steel beer sampling valve relies on hygienic sealing and medium diversion. Normally closed via a precision sealing structure (e.g., food-grade gaskets), it isolates beer from air and impurities to prevent contamination and flavor loss. During sampling, rotating the handwheel or pressing the valve drives the valve core to open the internal flow channel. Beer flows smoothly into the sampling container under the system's inherent pressure or slight diversion. After sampling, reversing the operation resets the valve core, and the sealing structure quickly restores a reliable seal, maintaining a sterile environment for subsequent beer storage and brewing.

Stainless Steel Sampling Valve Specification Chart

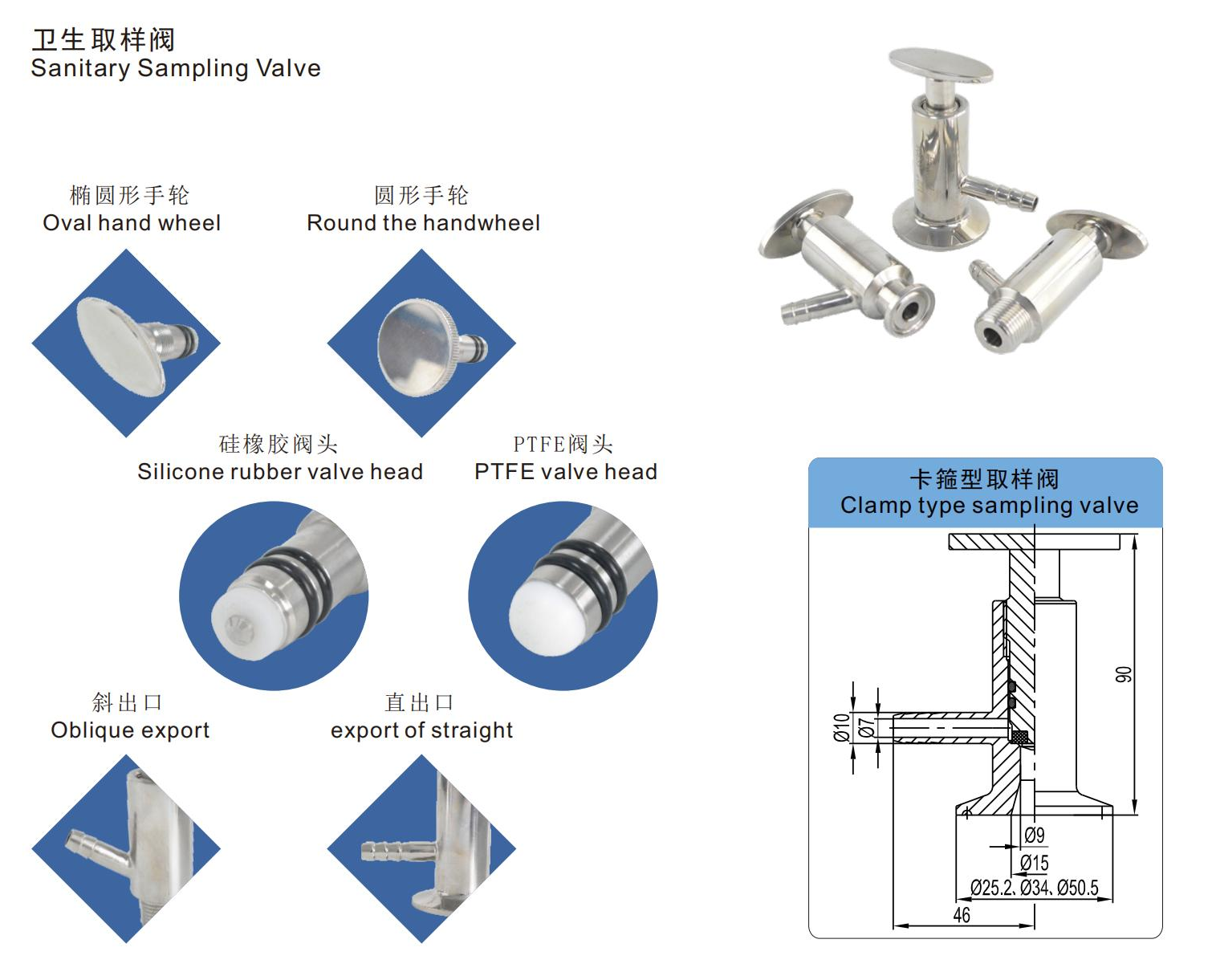

Size | 1/2",1-1/2" |

Connections | thread,clamp,weld |

Max.pressure | 10bar 145psi |

Min.pressure | Vacuum |

Temperature | -10℃ 50 F-120℃/248℃ |

Standard | 3A,ISO,DIN |

Body material | AISI1304, AISI316L |

Seal material | PTFE |

USAGR | Handle quick-opening type, handle wheel fine-turning type, pneumatic and hand-gas integrated four open mode |

Features

● Simple operation

● Simple structure

● Delicate appearance

● Fine craftsmanship

● Use the PTFE rubber durable and high purity

● Prevention of Pollution

● no dead angles

● Unique sealing structure

● Easy to clean

● Unique sealing structure, eliminate the sanitary blind corner. Easy to clean the sterilization process and Contamination free.

Application

The Sample valves are commonly used in industries such as food, chemical, pharmaceutical, cosmetics, beverage and biotechnology industries, where accurate sampling is crucial for quality control , analysis and testing purposes.

Working Principles

The working principle of the food-grade stainless steel beer sampling valve relies on hygienic sealing and medium diversion. Normally closed via a precision sealing structure (e.g., food-grade gaskets), it isolates beer from air and impurities to prevent contamination and flavor loss. During sampling, rotating the handwheel or pressing the valve drives the valve core to open the internal flow channel. Beer flows smoothly into the sampling container under the system's inherent pressure or slight diversion. After sampling, reversing the operation resets the valve core, and the sealing structure quickly restores a reliable seal, maintaining a sterile environment for subsequent beer storage and brewing.

Feature and Specification

Stainless Steel Sampling Valve Specification Chart

Size | 1/2",1-1/2" |

Connections | thread,clamp,weld |

Max.pressure | 10bar 145psi |

Min.pressure | Vacuum |

Temperature | -10℃ 50 F-120℃/248℃ |

Standard | 3A,ISO,DIN |

Body material | AISI1304, AISI316L |

Seal material | PTFE |

USAGR | Handle quick-opening type, handle wheel fine-turning type, pneumatic and hand-gas integrated four open mode |

Features

● Simple operation

● Simple structure

● Delicate appearance

● Fine craftsmanship

● Use the PTFE rubber durable and high purity

● Prevention of Pollution

● no dead angles

● Unique sealing structure

● Easy to clean

● Unique sealing structure, eliminate the sanitary blind corner. Easy to clean the sterilization process and Contamination free.

Application

The Sample valves are commonly used in industries such as food, chemical, pharmaceutical, cosmetics, beverage and biotechnology industries, where accurate sampling is crucial for quality control , analysis and testing purposes.