| Availability: | |

|---|---|

| Quantity: | |

JONENG

Stainless steel sanitary threaded proportional regulating diaphragm valve

The Stainless Steel Sanitary Threaded Proportional Regulating Diaphragm Valve is a hygienic valve designed for precise flow control. Its diaphragm provides leak-free operation, while threaded connections enable easy installation, making it suitable for food, pharmaceutical, and high-purity fluid systems

Working Principles

The Stainless Steel Sanitary Threaded Proportional Regulating Diaphragm Valve operates by adjusting the diaphragm position in response to a control signal, typically electrical or pneumatic. The diaphragm moves against the valve seat to regulate the flow proportionally, allowing precise and linear adjustment of liquids or gases. Threaded connections provide secure installation and easy integration into piping systems. The valve ensures a tight seal, preventing leaks and contamination, and the proportional control allows smooth, continuous flow changes. This mechanism is ideal for sanitary applications in food, pharmaceutical, and high-purity processes where accurate and reliable flow regulation is required.

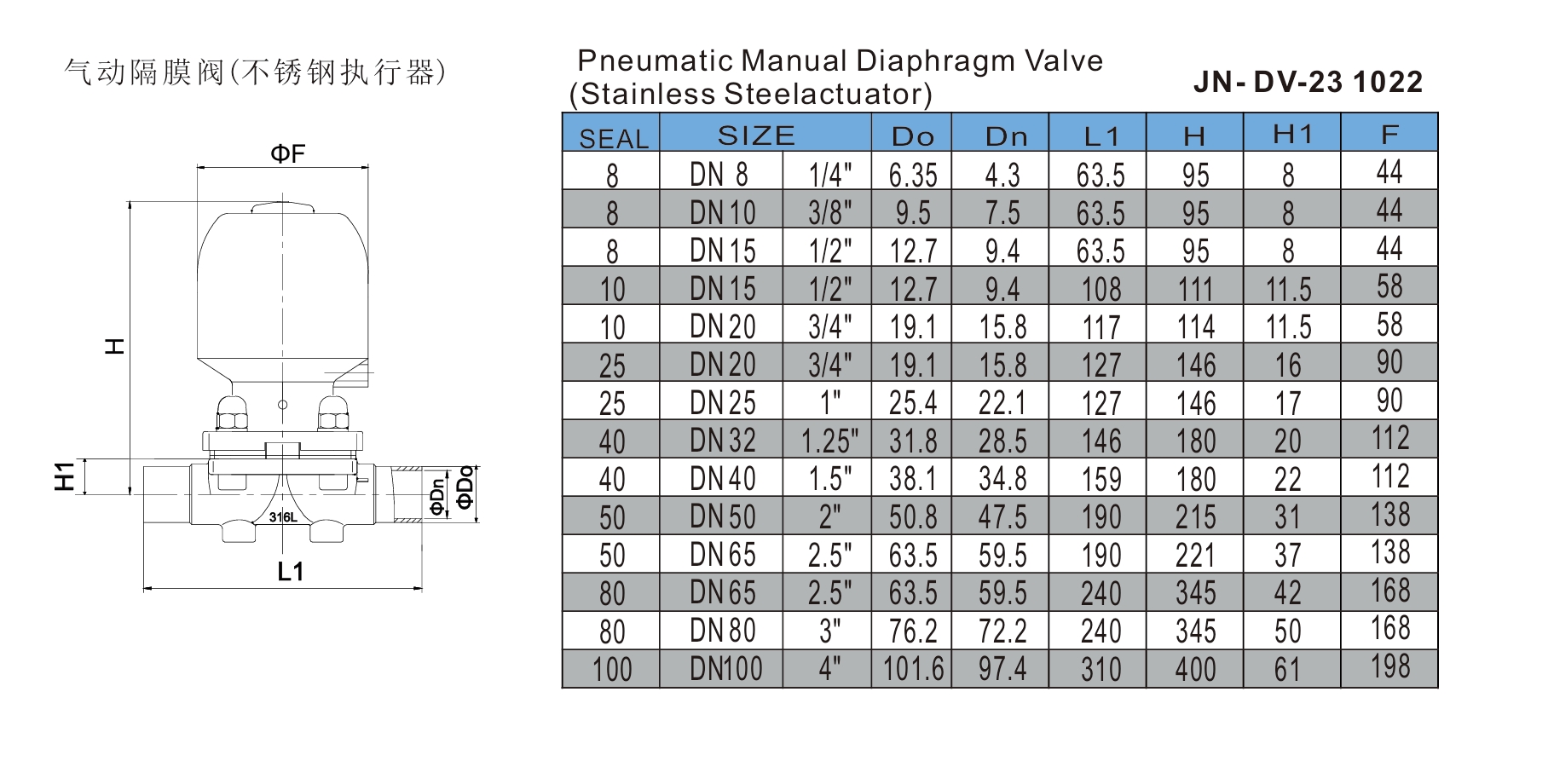

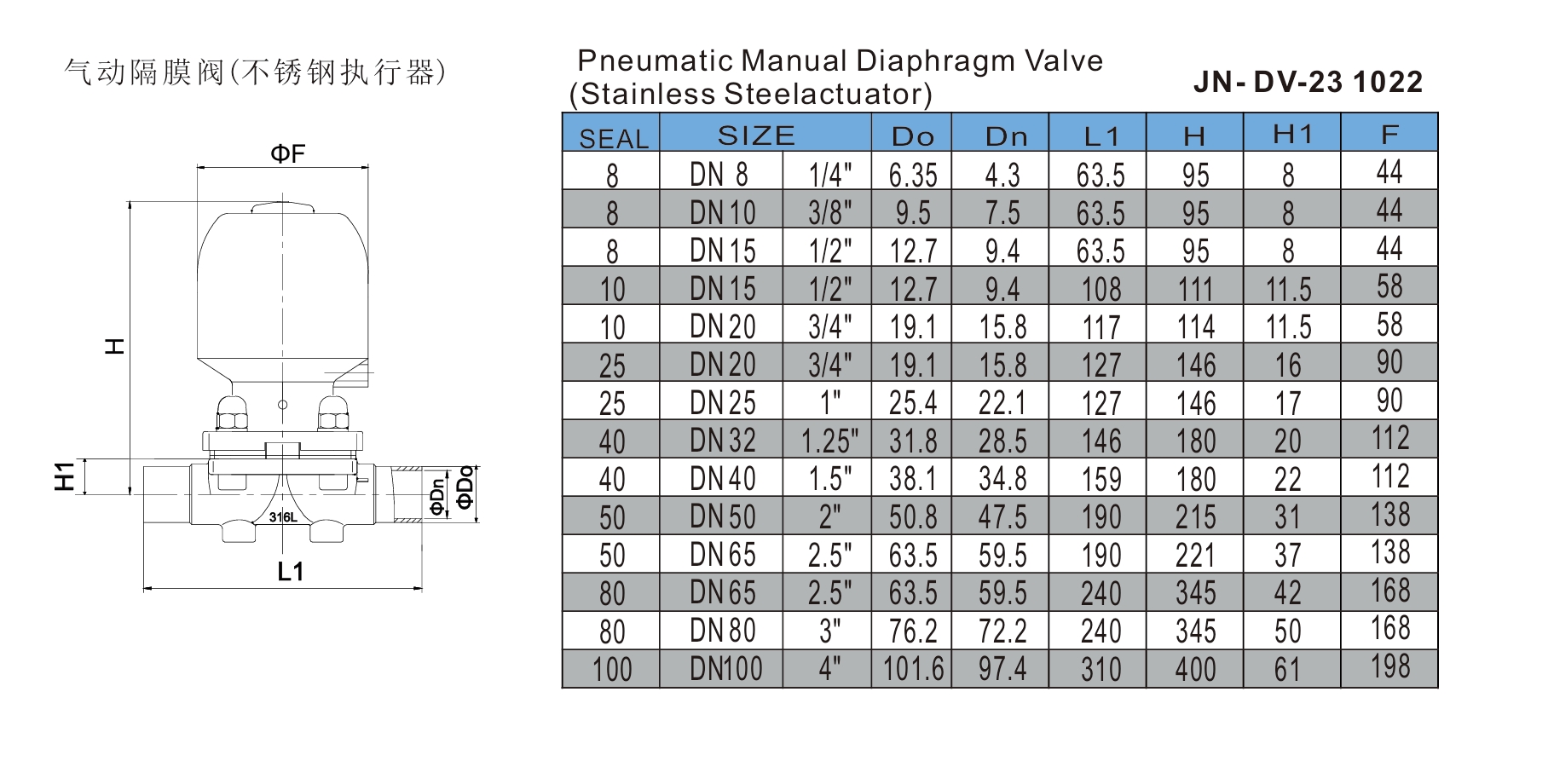

Stainless Steel Diaphragm Valve Specification Chart

| Parameter | Specification |

|---|---|

| Stainless Steel 304 / 316L | |

| Valve Type | Threaded Diaphragm, Proportional Regulating |

| Actuator Type | Electric or Pneumatic Proportional Actuator |

| Control Signal | 4–20 mA (Electric) / 0.2–1.0 MPa (Pneumatic) |

| Flow Characteristic | Linear / Equal Percentage |

| Connection Type | Threaded (Sanitary Standard) |

| Pressure Rating | Up to 10 bar (depends on size) |

| Temperature Range | -10°C to 150°C (diaphragm dependent) |

| Diaphragm Material | PTFE / EPDM / FDA-compliant options |

| Response Time | 1–3 seconds (actuator dependent) |

| Applications | Food, Pharmaceutical, Biotech, High-purity Systems |

Features

Proportional Flow Control – The valve adjusts flow linearly according to control signals, enabling precise and stable regulation in sensitive processes.

Diaphragm Seal Design – Ensures leak-free operation and maintains hygienic conditions, suitable for liquids, gases, or mildly corrosive media.

Threaded Connection – Provides easy, secure installation and integration into piping systems without welding or flanging.

Stainless Steel Construction – High corrosion resistance and durability, ideal for food, pharmaceutical, and high-purity fluid applications.

Rapid and Stable Response – Fast actuator response with minimal hysteresis ensures smooth and accurate flow control.

Hygienic and Easy to Clean – Smooth surfaces and sanitary design reduce contamination risk and allow simple cleaning or maintenance

Application

The Stainless Steel Sanitary Threaded Proportional Regulating Diaphragm Valve is used in industries requiring precise and hygienic flow control. Typical applications include food and beverage processing, pharmaceutical production, biotechnology, and high-purity water systems, where accurate, leak-free, and sanitary fluid regulation is essential.

Working Principles

The Stainless Steel Sanitary Threaded Proportional Regulating Diaphragm Valve operates by adjusting the diaphragm position in response to a control signal, typically electrical or pneumatic. The diaphragm moves against the valve seat to regulate the flow proportionally, allowing precise and linear adjustment of liquids or gases. Threaded connections provide secure installation and easy integration into piping systems. The valve ensures a tight seal, preventing leaks and contamination, and the proportional control allows smooth, continuous flow changes. This mechanism is ideal for sanitary applications in food, pharmaceutical, and high-purity processes where accurate and reliable flow regulation is required.

Feature and Specification

Stainless Steel Diaphragm Valve Specification Chart

| Parameter | Specification |

|---|---|

| Material | Stainless Steel 304 / 316L |

| Valve Type | Threaded Diaphragm, Proportional Regulating |

| Actuator Type | Electric or Pneumatic Proportional Actuator |

| Control Signal | 4–20 mA (Electric) / 0.2–1.0 MPa (Pneumatic) |

| Flow Characteristic | Linear / Equal Percentage |

| Connection Type | Threaded (Sanitary Standard) |

| Pressure Rating | Up to 10 bar (depends on size) |

| Temperature Range | -10°C to 150°C (diaphragm dependent) |

| Diaphragm Material | PTFE / EPDM / FDA-compliant options |

| Response Time | 1–3 seconds (actuator dependent) |

| Applications | Food, Pharmaceutical, Biotech, High-purity Systems |

Features

Proportional Flow Control – The valve adjusts flow linearly according to control signals, enabling precise and stable regulation in sensitive processes.

Diaphragm Seal Design – Ensures leak-free operation and maintains hygienic conditions, suitable for liquids, gases, or mildly corrosive media.

Threaded Connection – Provides easy, secure installation and integration into piping systems without welding or flanging.

Stainless Steel Construction – High corrosion resistance and durability, ideal for food, pharmaceutical, and high-purity fluid applications.

Rapid and Stable Response – Fast actuator response with minimal hysteresis ensures smooth and accurate flow control.

Hygienic and Easy to Clean – Smooth surfaces and sanitary design reduce contamination risk and allow simple cleaning or maintenance

Application

The Stainless Steel Sanitary Threaded Proportional Regulating Diaphragm Valve is used in industries requiring precise and hygienic flow control. Typical applications include food and beverage processing, pharmaceutical production, biotechnology, and high-purity water systems, where accurate, leak-free, and sanitary fluid regulation is essential.