| Availability: | |

|---|---|

| Quantity: | |

JN-BV 1001

JONENG

8481804090

The stainless steel sanitary quick-install duckbill manual butterfly valve is designed to provide an efficient and hygienic fluid control solution. Its "duckbill" sealing design ensures that the valve maintains good sealing performance during the opening and closing process to prevent fluid leakage or contamination. The quick-install design makes installation, disassembly and cleaning more convenient and meets strict hygienic standards. Through manual operation, users can accurately adjust the flow to ensure the stability of the production process and the safety of fluid transmission.

The stainless steel manual lever wafer 316L PTFE butterfly valve operates by rotating a circular disc mounted on a central shaft to control fluid flow. When the manual lever is turned, the shaft rotates the disc 90 degrees within the valve body. In the fully open position, the disc aligns parallel to the flow direction, allowing fluid to pass with minimal pressure loss. When rotated to the closed position, the disc turns perpendicular to the flow and presses against the PTFE seat, forming a tight seal. The PTFE seat provides excellent chemical resistance and low friction, ensuring smooth operation and reliable shutoff. The wafer-type design allows the valve to be installed between two flanges, using the pipeline bolts for positioning, making it compact, lightweight, and easy to maintain in various industrial piping systems.

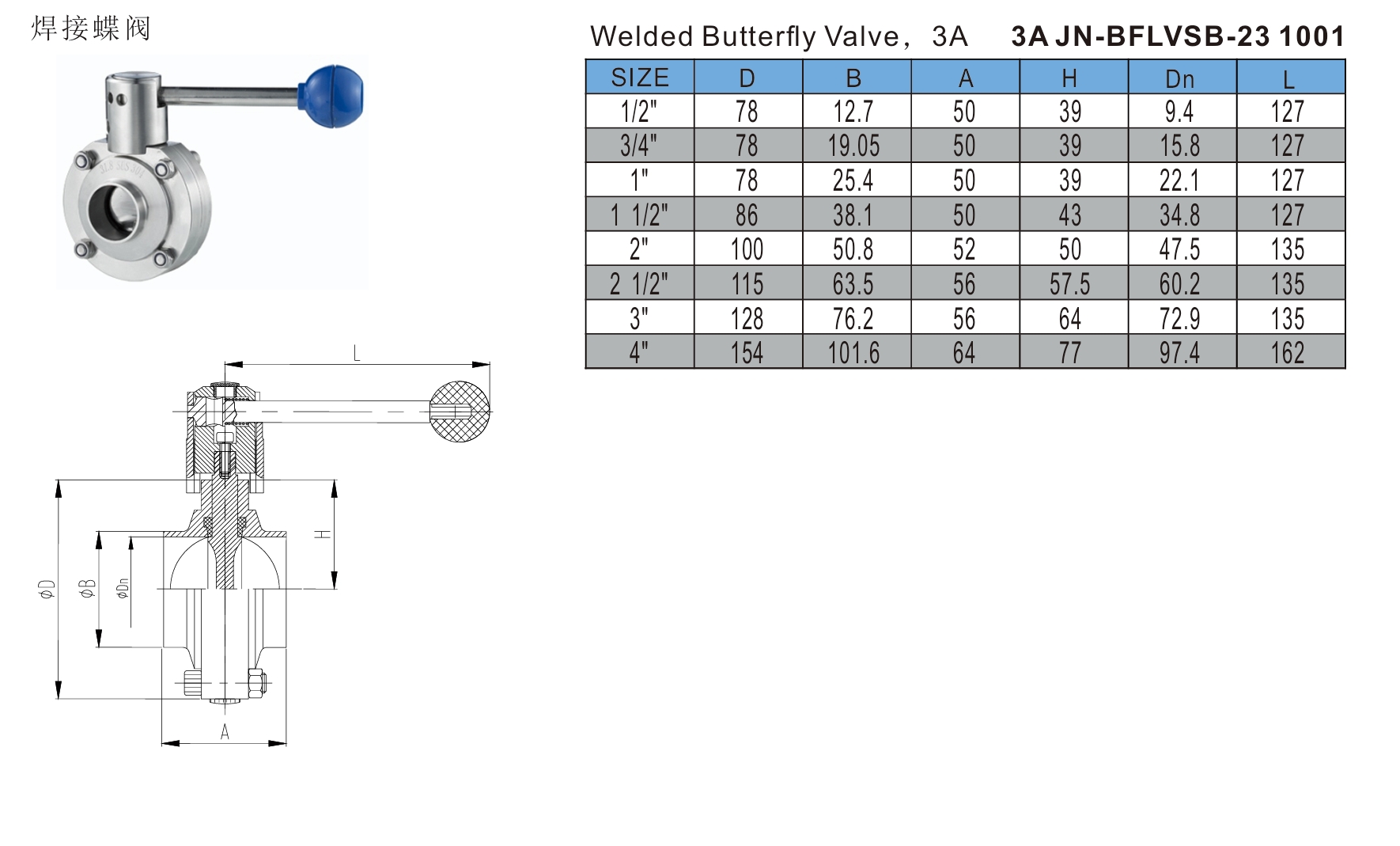

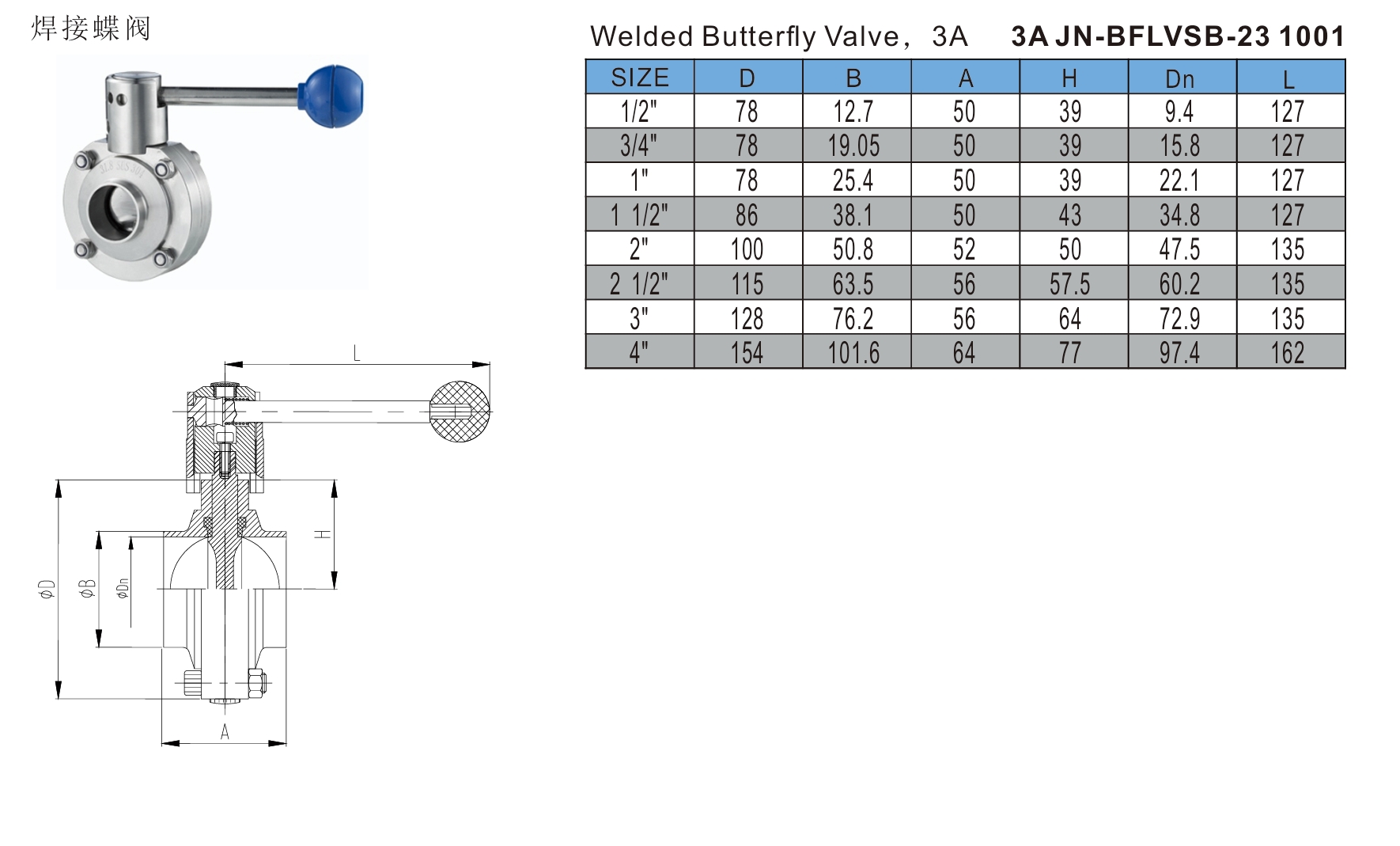

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Body | Stainless steel AISI316L or AISI 304 (1.4301/1.4404) |

Disc | AISI304 or AISI316L |

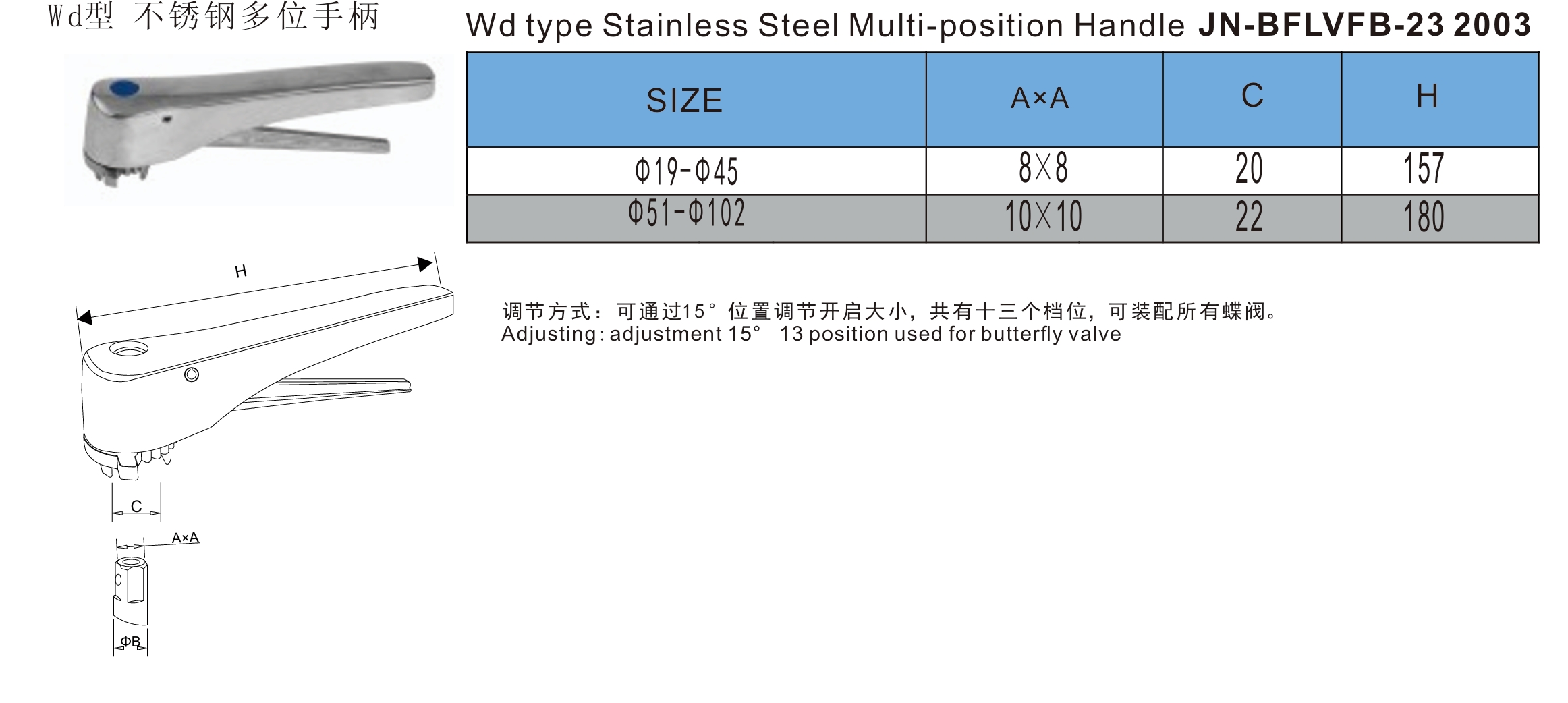

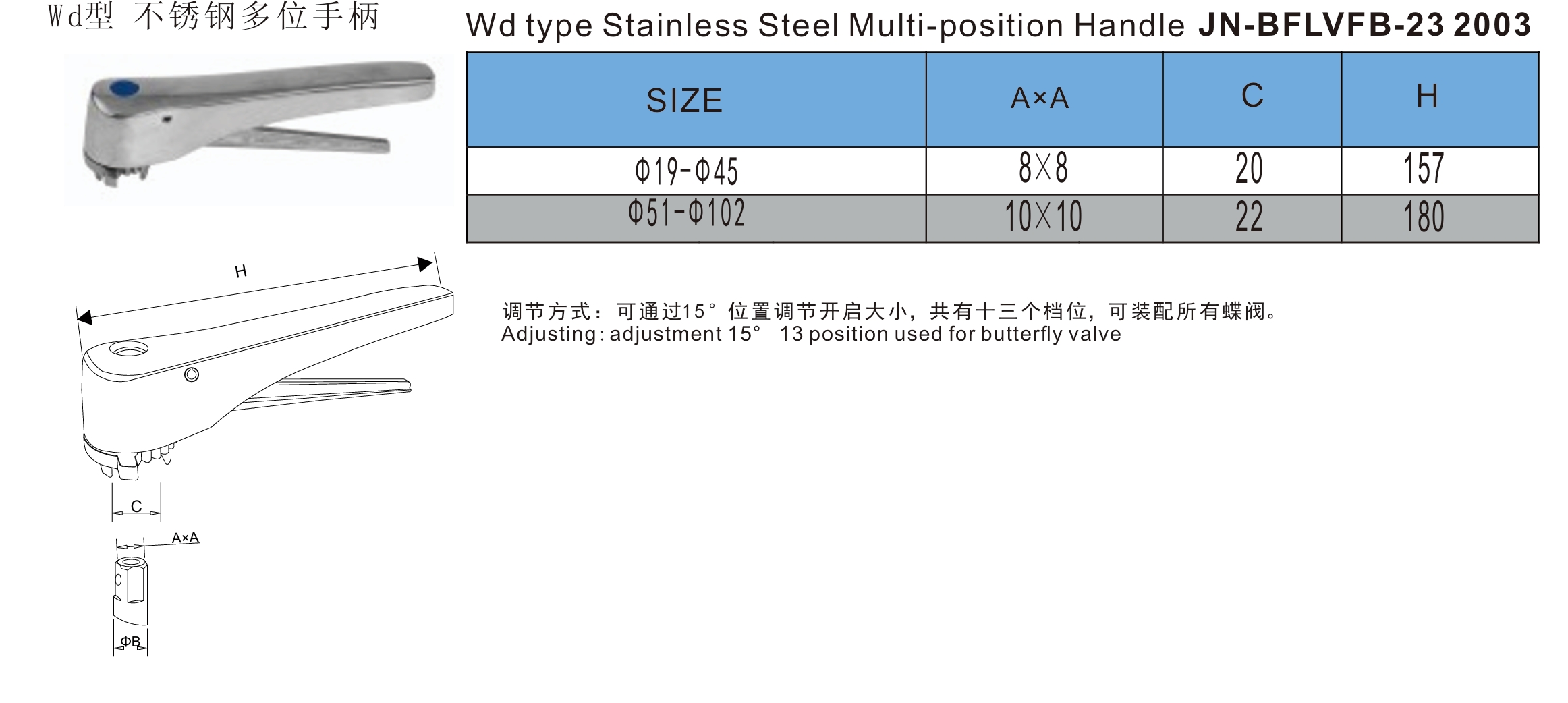

Pull-position handle | Stainless Steel Material, Round type or square type |

Multi-position Gripper Handle | ABS gripper handle, SS gripper handle, 2/3/4/12 positions to adjustment, Universal type |

Gasket | EPDM, VITON(FPM), Silicone, different color is available |

Bushing | EPDM or PTFE, other material request |

Nut | Stainless Steel 304 or 316 Material or other request |

Bolt | Stainless Steel 304 or 316 Material or other request |

● The stainless steel sanitary quick-install duckbill manual butterfly valve disc adopts a duckbill sealing structure to ensure the sealing and hygiene of the system.

● The stainless steel sanitary quick-install duckbill manual butterfly valve is equipped with a quick-install connection interface, which can be quickly installed and disassembled.

● The stainless steel sanitary quick-install duckbill manual butterfly valve provides precise flow control by manually adjusting the valve disc switch.

● The stainless steel sanitary quick-install duckbill manual butterfly valve adopts a multiple sealing design, including duckbill and O-ring sealing.

● The stainless steel sanitary quick-install duckbill manual butterfly valve can withstand high temperature and high pressure, and is suitable for the control of high-temperature fluids such as steam and hot water.

● The streamlined design of the stainless steel sanitary quick-install duckbill manual butterfly valve disc reduces fluid resistance and provides a smooth flow path.

Stainless steel sanitary quick-install duckbill manual butterfly valve is mainly used in the following industries: Food industry: used for fluid control of beverages, dairy products, juice, beer, etc. Pharmaceutical industry: ensure hygiene and fluid control in the production process of drugs. Beverage industry: used for fluid regulation and sealing of various beverage production lines. Cosmetics industry: control the flow of raw materials and finished products to meet hygiene standards. Chemical industry: suitable for milder chemical fluid control.

Working Principles

The stainless steel manual lever wafer 316L PTFE butterfly valve operates by rotating a circular disc mounted on a central shaft to control fluid flow. When the manual lever is turned, the shaft rotates the disc 90 degrees within the valve body. In the fully open position, the disc aligns parallel to the flow direction, allowing fluid to pass with minimal pressure loss. When rotated to the closed position, the disc turns perpendicular to the flow and presses against the PTFE seat, forming a tight seal. The PTFE seat provides excellent chemical resistance and low friction, ensuring smooth operation and reliable shutoff. The wafer-type design allows the valve to be installed between two flanges, using the pipeline bolts for positioning, making it compact, lightweight, and easy to maintain in various industrial piping systems.

Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Features

● The stainless steel sanitary quick-install duckbill manual butterfly valve disc adopts a duckbill sealing structure to ensure the sealing and hygiene of the system.

● The stainless steel sanitary quick-install duckbill manual butterfly valve is equipped with a quick-install connection interface, which can be quickly installed and disassembled.

● The stainless steel sanitary quick-install duckbill manual butterfly valve provides precise flow control by manually adjusting the valve disc switch.

● The stainless steel sanitary quick-install duckbill manual butterfly valve adopts a multiple sealing design, including duckbill and O-ring sealing.

● The stainless steel sanitary quick-install duckbill manual butterfly valve can withstand high temperature and high pressure, and is suitable for the control of high-temperature fluids such as steam and hot water.

● The streamlined design of the stainless steel sanitary quick-install duckbill manual butterfly valve disc reduces fluid resistance and provides a smooth flow path.

Application

Stainless steel sanitary quick-install duckbill manual butterfly valve is mainly used in the following industries: Food industry: used for fluid control of beverages, dairy products, juice, beer, etc. Pharmaceutical industry: ensure hygiene and fluid control in the production process of drugs. Beverage industry: used for fluid regulation and sealing of various beverage production lines. Cosmetics industry: control the flow of raw materials and finished products to meet hygiene standards. Chemical industry: suitable for milder chemical fluid control.