Sanitary Stainless Steel Union swing wafer Check Valve

Sanitary Stainless Steel Union Swing Wafer Check Valve is a compact one-way valve designed to prevent reverse flow in sanitary pipelines. Its swing-type disc opens freely with forward flow and closes automatically, while the union wafer structure allows easy installation and maintenance in hygienic systems.

Working Principles

The working principle of a Sanitary Stainless Steel Union Swing Wafer Check Valve is based on a swing-type disc that responds to fluid direction and gravity. When fluid flows in the correct direction, the pressure pushes the disc to swing open, allowing smooth passage through the valve with minimal resistance. When the flow slows, stops, or reverses, the disc swings back toward the seat under gravity and reverse pressure, forming a tight seal that prevents backflow. The wafer and union structure enables compact installation between pipe connections, ensuring hygienic operation, easy maintenance, and reliable protection for pumps and sanitary piping systems.

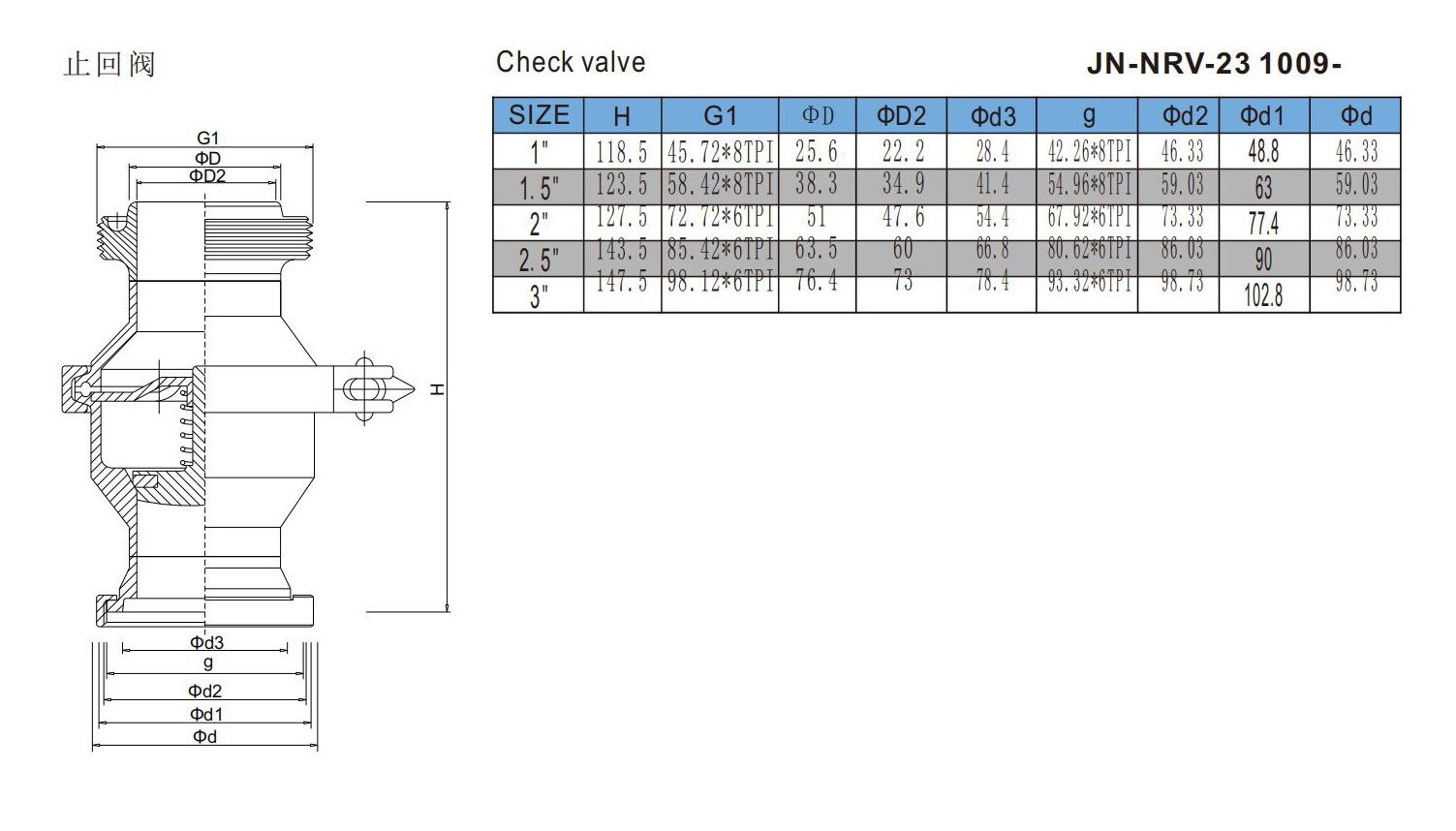

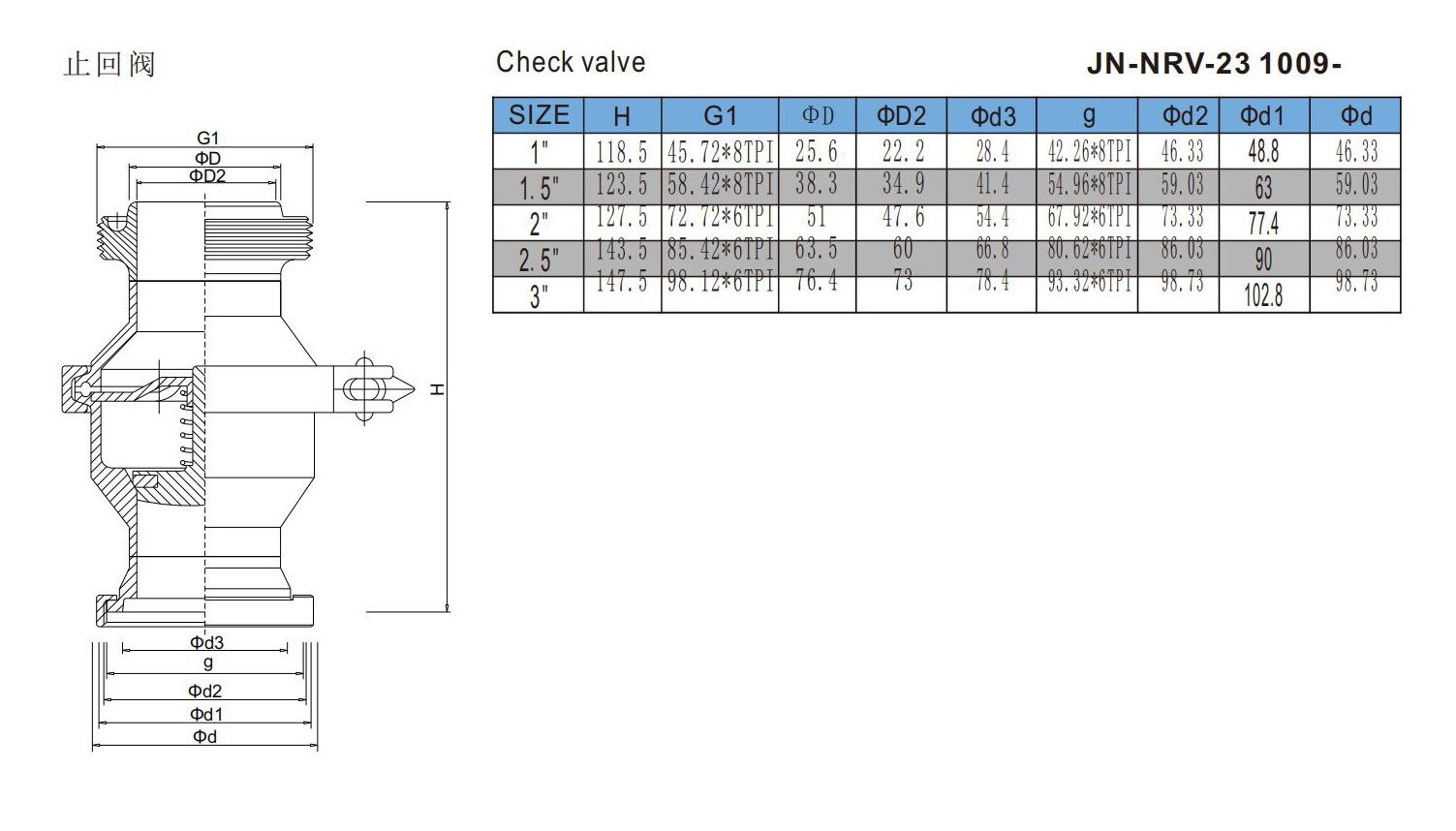

Stainless Steel Angle Seat Valve Specification Chart

Size range | 1/2”-6”,DN15-DN150 |

Material | Forged 304 or 316L, both valve body and valve disc is made from forging raw material |

Seal material | EPDM, NBR, VITION, SILICONE |

Working Pressure | 0.2-10bar |

Working Temperature | -10°C ~ +121°C |

Inner surface finish is Ra0.6 to meet the requirement of the food industries |

Connection End | Weld, Clamp, Union, Flange,male threaded, female threaded |

Connection Standards | DIN, SMS, 3A, ISO |

Vertical installation preferred |

The min. pressure difference is 0.08bar to open the valve |

Flow direction is from the bottom to the top side only |

Precision machined body, stem, disc, free draining |

Disc tapered for smooth body and reduce draining |

The check valves can not be used for sticky ,adhesive, viscous products. |

Features

Constructed from high-quality stainless steel, providing excellent corrosion resistance and hygienic performance in sanitary piping systems.

Swing-type disc design allows smooth forward flow with low pressure loss and automatic closure to prevent backflow.

Union wafer structure enables compact installation and easy disassembly for inspection or maintenance.

Smooth internal surfaces reduce product retention and support clean, contamination-free operation.

Reliable one-way sealing protects pumps and equipment, ensuring stable operation in food, beverage, and pharmaceutical applications.

Application

Sanitary Stainless Steel Union Swing Wafer Check Valves are widely used in dairy and beverage industries to prevent backflow in milk, juice, and water pipelines. They are also applied in pharmaceutical and biotechnology processing, where maintaining one-directional flow is essential for sterile conditions. In addition, these valves are suitable for food processing and cosmetic manufacturing, protecting pumps and process equipment while ensuring hygienic operation and compliance with sanitary standards.