| Availability: | |

|---|---|

| Quantity: | |

JONENG

Sanitary stainless steel three-piece weld floating ball valve

The Sanitary Stainless Steel Three-Piece Weld Floating Ball Valve is a hygienic valve designed for full bore flow control. Its floating ball mechanism ensures tight shutoff, while the three-piece welded design allows easy maintenance and reliable operation in sanitary and industrial fluid systems

Working Principles

The Sanitary Stainless Steel Three-Piece Weld Floating Ball Valve operates using a spherical ball with a central bore that rotates within the valve body. When the handle or actuator turns the ball 90 degrees, the bore aligns with the pipeline to allow flow or rotates perpendicular to block the flow. The floating ball is held between two elastomeric seats, which press against the ball to create a tight seal, ensuring leak-free operation. The three-piece welded design allows easy disassembly for maintenance without removing the entire valve from the pipeline. This mechanism provides reliable, rapid, and hygienic flow control in food, pharmaceutical, and industrial applications

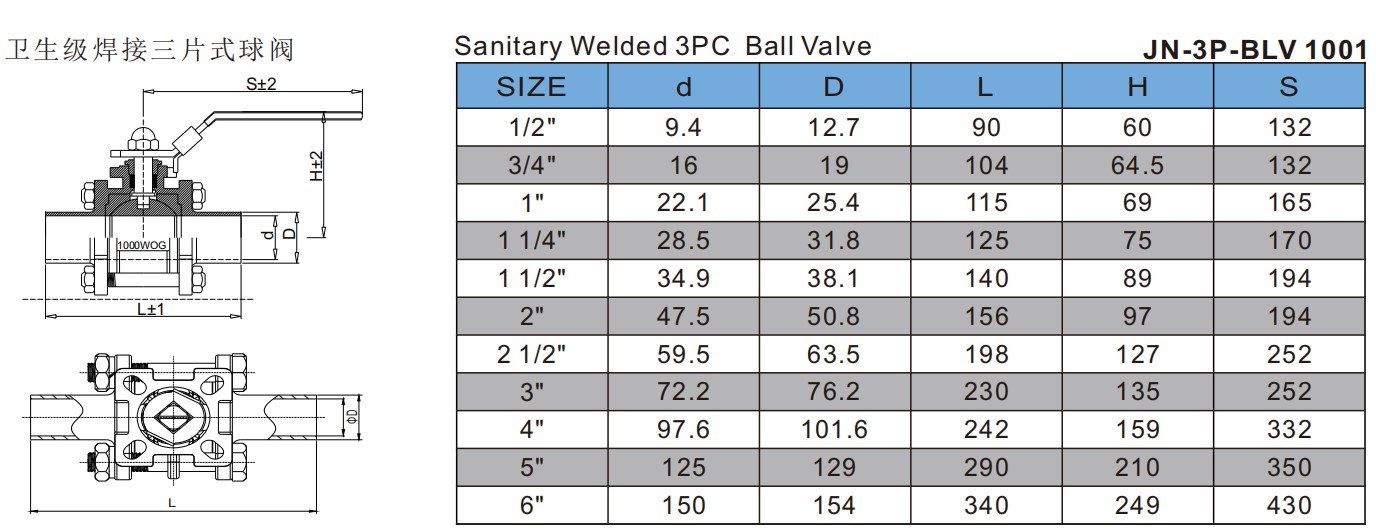

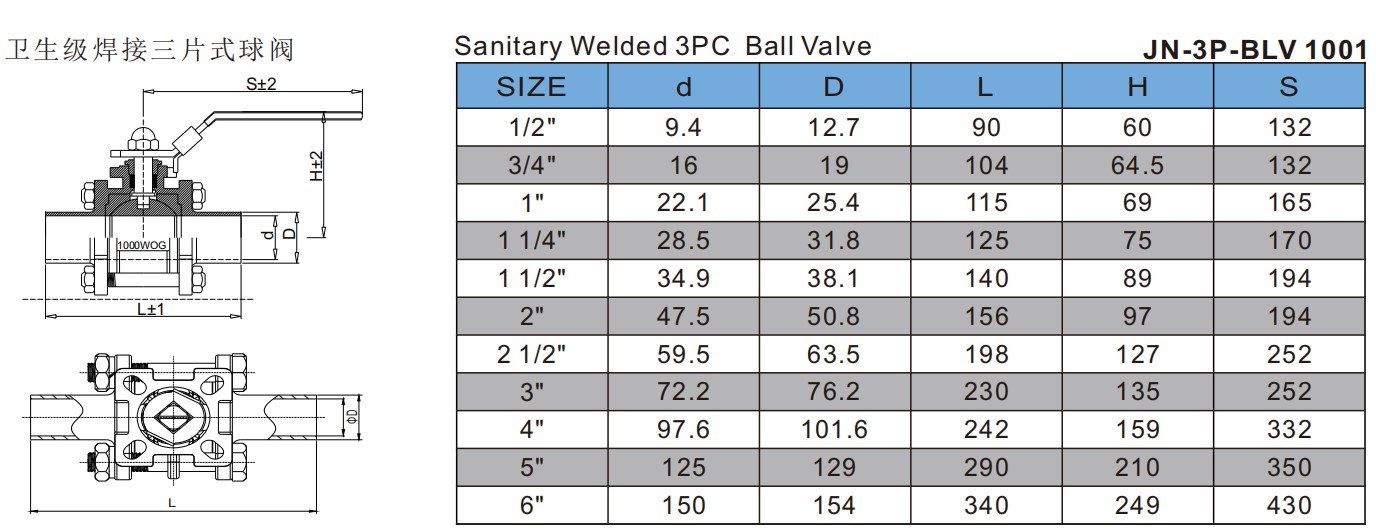

Specification Chart

Max. working pressure | 150 PSI |

Temperature range | -20° ~ +150°C or higher upon request |

Sizes available | 1/2" to 4" |

| End connection | Tri-Clamp, Butt-Weld, Flange, Threaded |

Body material | Stainless Steel 316L |

Ball material | Stainless Steel 316L |

Seal material | FDA Approved EPDM, Silicone, Viton |

Actuator Options | Manual, Pneumatic |

Surface Finish | Ra ≤ 0.8μm (Standard), Ra |

Flow Control | Linear |

Features

Floating Ball Design – The ball is held by elastomeric seats, providing tight, leak-free shutoff and reliable flow control.

Three-Piece Welded Construction – Allows easy disassembly for maintenance without removing the valve from the pipeline.

Stainless Steel Body – Corrosion-resistant and durable, suitable for sanitary, food, pharmaceutical, and industrial applications.

Full Bore Flow – Provides minimal pressure drop and smooth flow, ideal for high-purity or viscous media.

Hygienic Design – Smooth surfaces and sanitary construction reduce contamination risk and support clean-in-place (CIP) processes.

Versatile Operation – Can be operated manually or with pneumatic/electric actuators for automated control

Application

The Sanitary Stainless Steel Three-Piece Weld Floating Ball Valve is commonly used in industries requiring reliable and hygienic shutoff. Typical applications include dairy and beverage processing, pharmaceutical manufacturing, biotechnology, and cosmetic production, where clean, leak-free, and easy-to-maintain valves ensure process efficiency and product safety

Working Principles

The Sanitary Stainless Steel Three-Piece Weld Floating Ball Valve operates using a spherical ball with a central bore that rotates within the valve body. When the handle or actuator turns the ball 90 degrees, the bore aligns with the pipeline to allow flow or rotates perpendicular to block the flow. The floating ball is held between two elastomeric seats, which press against the ball to create a tight seal, ensuring leak-free operation. The three-piece welded design allows easy disassembly for maintenance without removing the entire valve from the pipeline. This mechanism provides reliable, rapid, and hygienic flow control in food, pharmaceutical, and industrial applications

Specification Chart

Max. working pressure | 150 PSI |

Temperature range | -20° ~ +150°C or higher upon request |

Sizes available | 1/2" to 4" |

End connection | Tri-Clamp, Butt-Weld, Flange, Threaded |

Body material | Stainless Steel 316L |

Ball material | Stainless Steel 316L |

Seal material | FDA Approved EPDM, Silicone, Viton |

Actuator Options | Manual, Pneumatic |

Surface Finish | Ra ≤ 0.8μm (Standard), Ra |

Flow Control | Linear |

Features

Floating Ball Design – The ball is held by elastomeric seats, providing tight, leak-free shutoff and reliable flow control.

Three-Piece Welded Construction – Allows easy disassembly for maintenance without removing the valve from the pipeline.

Stainless Steel Body – Corrosion-resistant and durable, suitable for sanitary, food, pharmaceutical, and industrial applications.

Full Bore Flow – Provides minimal pressure drop and smooth flow, ideal for high-purity or viscous media.

Hygienic Design – Smooth surfaces and sanitary construction reduce contamination risk and support clean-in-place (CIP) processes.

Versatile Operation – Can be operated manually or with pneumatic/electric actuators for automated control