| Availability: | |

|---|---|

| Quantity: | |

Chinese manufacturer Joneng offers stainless steel sanitary non-retention ball valves. Buying these stainless steel sanitary non-retention ball valves directly offers excellent value for money and superior quality.

JONENG

A ball valve is a type of valve that opens and closes by rotating a ball around the valve stem axis. It is mainly used for on-off control, regulation, and throttling of fluids in pipelines, widely applied in industrial piping systems such as petroleum, chemical engineering, natural gas, as well as urban water supply and drainage, heating, and food and pharmaceutical industry pipelines. There are various types: structurally, they include floating ball, trunnion-mounted ball, and three-way types; by material, they cover metal and plastic variants. Designed to enable quick opening and closing, it features reliable sealing, low flow resistance, adaptability to different media and working conditions, along with easy operation and maintenance, serving as a key control component in piping systems.

The working principle of the stainless steel actuator-centered clamping type non-holding ball valve is that the stainless steel actuator drives the valve stem to rotate the ball with a through hole inside the valve body by 0-90° to achieve fluid on-off control—when the through hole aligns with the pipeline diameter, fluid flows through; when rotated 90°, the ball blocks the channel. The centered clamping structure fixes the valve body by clamping it with flanges at both ends, and the non-holding feature enables the actuator to drive the ball back to the preset position after power failure without additional energy to maintain the position. Using this product allows for rapid and precise fluid on-off control and automatic operation, with advantages such as reliable sealing, corrosion and contamination resistance, easy installation and maintenance, and stable operation. Additionally, the non-holding reset function enhances system safety redundancy, preventing operational chaos after power failure.

Valve Size | Standard sizes: 1/2"-4" (corresponding to nominal diameter DN10-DN100); customized versions can be extended to DN125. Common specification range for special working conditions: 1"-4" (DN25-DN100). |

Connection Type | Mainstream: clamp connection; also supports thread, welding, and flange connections. Compatible with industry standard interfaces such as DN, SMS, ISO, IDF, RJT, and ASME BPE to meet different pipeline assembly needs. |

Operating Pressure Range | Regular working conditions: 0-1.0MPa (10bar); customized versions with special sealing materials and temperature adaptability can be extended to 1.0-3.0MPa (10-30bar). |

Constant Pressure Range | Recommended long-term constant working pressure: ≤1.0MPa (ensures stable sealing performance and service life). For higher constant pressure, enhanced seals and manufacturer's working condition verification are required. |

| Operating Temperature | Varies with sealing materials: -20℃-130℃ (standard PTFE seal); optional standard version: -30℃-150℃; customized high-temperature resistant version: -30℃-200℃. |

| Control Type | Mainly stainless steel electric/pneumatic actuator control. Achieves automatic control via 4-20mA/0-10V input signal, with non-holding feature for automatic reset after power failure. Compatible with manual control for mode switching. |

| Surface Treatment | Valve body: polished finish (standard precision Ra≤0.8μm); customized hygienic-grade versions (for pharmaceutical/food industries): Ra≤0.3μm, ensuring no medium residue dead ends and compliance with hygiene standards. |

| Sealing Material | Mainstream: PTFE (polytetrafluoroethylene); optional materials: TFM, PTFE+carbon fiber, PEEK. Gasket seals mostly meet FDA 177.2600 standard, suitable for hygienic working conditions. |

| Valve Body Material | Mainly 304 stainless steel (1.4301), 316L stainless steel (1.4404); high-end hygienic scenarios (e.g., biopharmaceuticals): ASME BPE 316L (1.4435) for higher purity and corrosion resistance requirements. |

| Cleaning Compatibility | Features non-retention flow channel design, supporting CIP (Clean-in-Place) and SIP (Sterilize-in-Place) with high-temperature steam cleaning. Complies with 3-A and FDA hygiene certifications, no medium residue dead ends, suitable for high-cleanliness standards in food, pharmaceutical, and cosmetic industries. |

1. Stainless steel integrated precision-cast valve body + center clamping structure

2. Non-holding intelligent actuator + power-off automatic reset technology

3. Reinforced double-sealing surface design + food-grade sealing material

4. Non-retention flow channel design + high-precision surface polishing (Ra≤0.3μm)

5.Optimized coaxiality between actuator and valve stem + precise torque adaptation technology

1. No complex procedures required for installation and disassembly; the valve body bears force evenly without deformation, and the sealing surface fits more tightly.

2. No additional energy needed to maintain the valve's working position; it can quickly reset to the preset safe working condition after power failure.

3. Stable sealing performance with no leakage, wear-resistant and corrosion-resistant, suitable for various working conditions such as water, steam, and chemical media.

4. No dead ends in the flow channel to avoid medium residue, thorough and efficient cleaning, complying with 3-A, FDA and other hygiene certification standards.

5. Fast opening and closing response speed, high operation accuracy, and seamless adaptation to automatic control systems.

Working Principles

The working principle of the stainless steel actuator-centered clamping type non-holding ball valve is that the stainless steel actuator drives the valve stem to rotate the ball with a through hole inside the valve body by 0-90° to achieve fluid on-off control—when the through hole aligns with the pipeline diameter, fluid flows through; when rotated 90°, the ball blocks the channel. The centered clamping structure fixes the valve body by clamping it with flanges at both ends, and the non-holding feature enables the actuator to drive the ball back to the preset position after power failure without additional energy to maintain the position. Using this product allows for rapid and precise fluid on-off control and automatic operation, with advantages such as reliable sealing, corrosion and contamination resistance, easy installation and maintenance, and stable operation. Additionally, the non-holding reset function enhances system safety redundancy, preventing operational chaos after power failure.

Feature and Specification

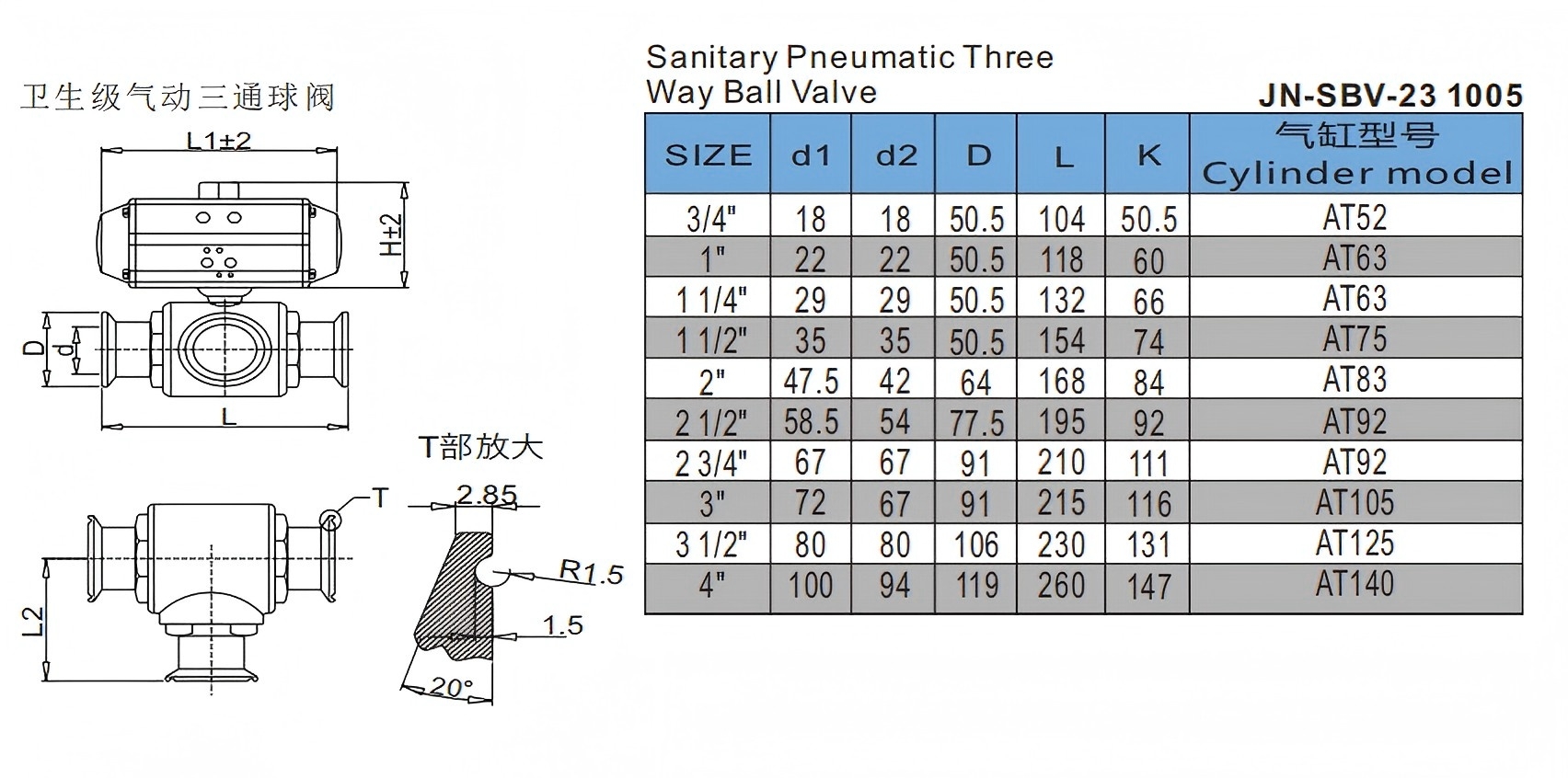

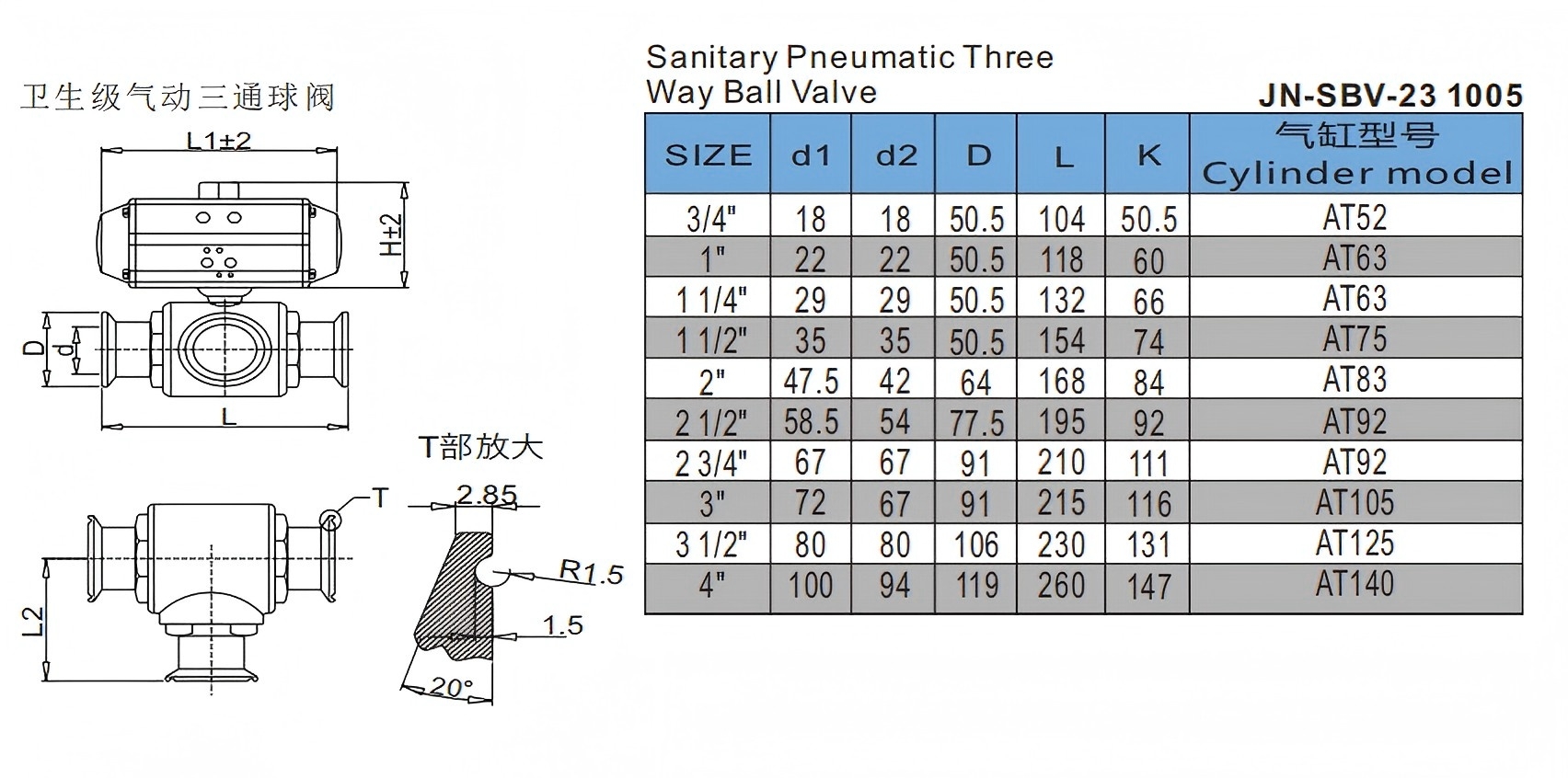

Stainless Steel Pipe Holder Specification Chart

Valve Size | Standard sizes: 1/2"-4" (corresponding to nominal diameter DN10-DN100); customized versions can be extended to DN125. Common specification range for special working conditions: 1"-4" (DN25-DN100). |

Connection Type | Mainstream: clamp connection; also supports thread, welding, and flange connections. Compatible with industry standard interfaces such as DN, SMS, ISO, IDF, RJT, and ASME BPE to meet different pipeline assembly needs. |

Operating Pressure Range | Regular working conditions: 0-1.0MPa (10bar); customized versions with special sealing materials and temperature adaptability can be extended to 1.0-3.0MPa (10-30bar). |

Constant Pressure Range | Recommended long-term constant working pressure: ≤1.0MPa (ensures stable sealing performance and service life). For higher constant pressure, enhanced seals and manufacturer's working condition verification are required. |

| Operating Temperature | Varies with sealing materials: -20℃-130℃ (standard PTFE seal); optional standard version: -30℃-150℃; customized high-temperature resistant version: -30℃-200℃. |

| Control Type | Mainly stainless steel electric/pneumatic actuator control. Achieves automatic control via 4-20mA/0-10V input signal, with non-holding feature for automatic reset after power failure. Compatible with manual control for mode switching. |

| Surface Treatment | Valve body: polished finish (standard precision Ra≤0.8μm); customized hygienic-grade versions (for pharmaceutical/food industries): Ra≤0.3μm, ensuring no medium residue dead ends and compliance with hygiene standards. |

| Sealing Material | Mainstream: PTFE (polytetrafluoroethylene); optional materials: TFM, PTFE+carbon fiber, PEEK. Gasket seals mostly meet FDA 177.2600 standard, suitable for hygienic working conditions. |

| Valve Body Material | Mainly 304 stainless steel (1.4301), 316L stainless steel (1.4404); high-end hygienic scenarios (e.g., biopharmaceuticals): ASME BPE 316L (1.4435) for higher purity and corrosion resistance requirements. |

| Cleaning Compatibility | Features non-retention flow channel design, supporting CIP (Clean-in-Place) and SIP (Sterilize-in-Place) with high-temperature steam cleaning. Complies with 3-A and FDA hygiene certifications, no medium residue dead ends, suitable for high-cleanliness standards in food, pharmaceutical, and cosmetic industries. |

Features

1. Stainless steel integrated precision-cast valve body + center clamping structure

2. Non-holding intelligent actuator + power-off automatic reset technology

3. Reinforced double-sealing surface design + food-grade sealing material

4. Non-retention flow channel design + high-precision surface polishing (Ra≤0.3μm)

5.Optimized coaxiality between actuator and valve stem + precise torque adaptation technology

Application

1. No complex procedures required for installation and disassembly; the valve body bears force evenly without deformation, and the sealing surface fits more tightly.

2. No additional energy needed to maintain the valve's working position; it can quickly reset to the preset safe working condition after power failure.

3. Stable sealing performance with no leakage, wear-resistant and corrosion-resistant, suitable for various working conditions such as water, steam, and chemical media.

4. No dead ends in the flow channel to avoid medium residue, thorough and efficient cleaning, complying with 3-A, FDA and other hygiene certification standards.

5. Fast opening and closing response speed, high operation accuracy, and seamless adaptation to automatic control systems.