| Availability: | |

|---|---|

| Quantity: | |

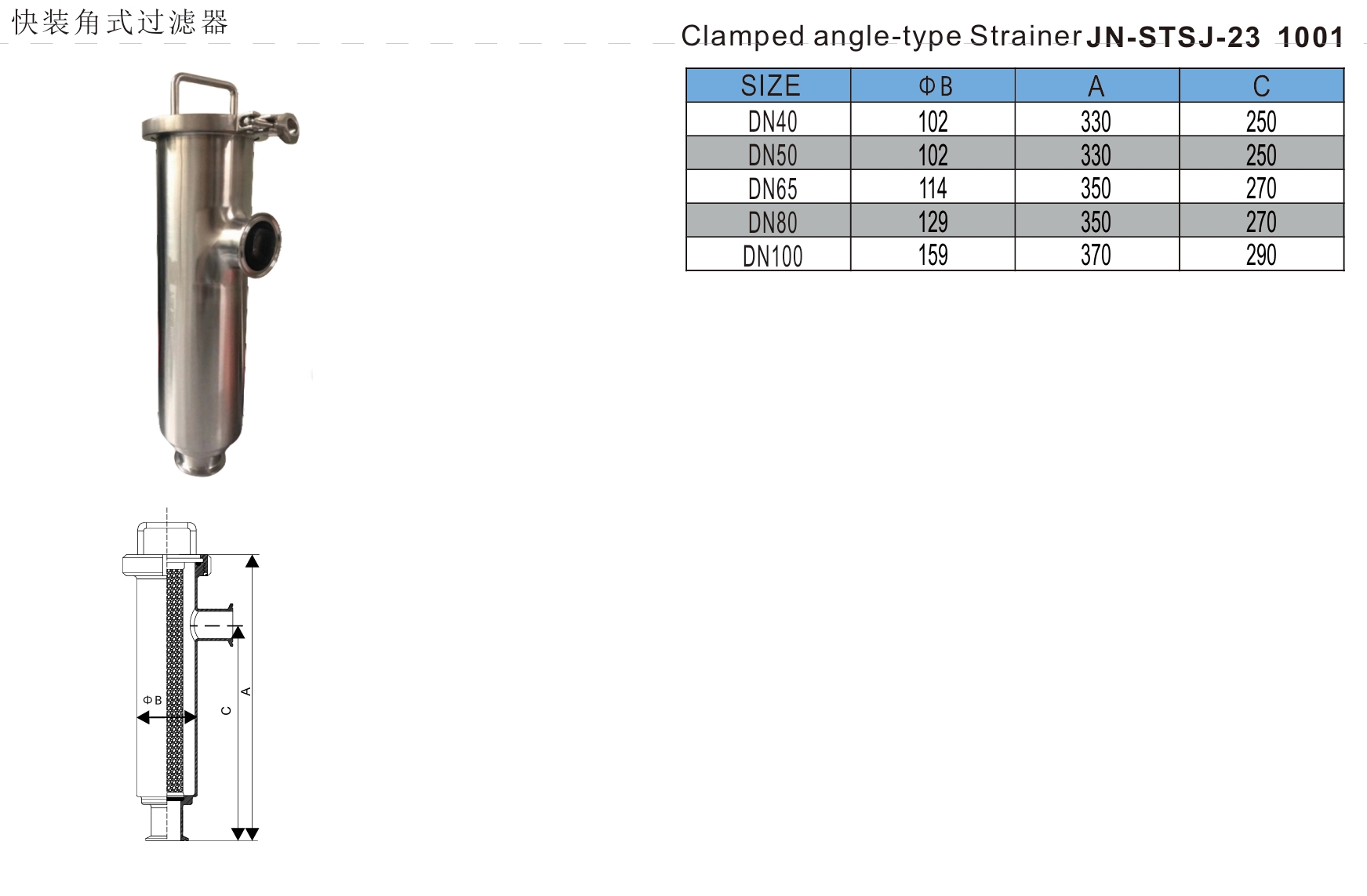

The stainless steel sanitary quick-install angle filter is a filtering device designed for sanitary environments. It is made of stainless steel. Its main function is to remove solid impurities, particles and impurities in the fluid to ensure the quality of the liquid in the production process. Through efficient filtration, it can maintain the purity of the production environment, prevent pollutants from affecting product quality, and improve production efficiency. The stainless steel sanitary quick-install angle filter is usually used in liquid pipelines in industries such as food, pharmaceuticals and beverages, especially at the inlet or outlet of the fluid in the production process. Common types of stainless steel sanitary quick-install angle filters include: single-net filter, multi-net filter, Y-type filter, filter with drain valve, microporous filter.

JN-STZT-23 1010

JONENG

8421219990

Stainless Steel High Perfomace Quick-install Angle Filter Cartridge

The stainless steel sanitary quick-install angle filter is designed to provide efficient and convenient fluid filtration solutions in industrial environments with strict hygiene requirements. Its angle structure and quick-install design allow the filter to be easily disassembled and cleaned without affecting production efficiency, ensuring that the equipment always maintains a good sanitary state. The use of high-precision filter mesh can effectively remove impurities, particles and sediments in the fluid, ensure the purity and safety of the fluid, and is particularly suitable for industries such as food, pharmaceuticals, beverages, etc. that have high requirements for hygiene standards, ensuring that the production process is not contaminated and improving product quality and process stability.

Working Principles

The working principle of the stainless steel sanitary quick-install angle filter is based on the process of fluid passing through the filter. When the fluid enters the filter, the fluid enters the filter chamber through its angle-designed pipe, and the solid particles and impurities in the fluid are captured by the filter, while the clean fluid flows out through the mesh. The stainless steel sanitary quick-install angle filter can maintain the quality of the liquid during the production process and prevent impurities from contaminating or damaging subsequent equipment or processes. This filter also has convenient cleaning and maintenance functions, which reduces downtime in production and improves the overall operating efficiency of the equipment.

The options of the stainless steel sanitary quick-install angle filter include:

Filter mesh aperture: filter meshes with different apertures can be selected according to needs.

Drain valve: automatic or manual drain function can be selected.

Material: 304 or 316L stainless steel materials can be selected.

Sealing material: sanitary sealing materials such as EPDM and PTFE.

Interface type: different interface methods such as clamp type and quick installation type can be selected.

Filtration level: single-net or multi-net structure can be selected to meet different filtration needs.

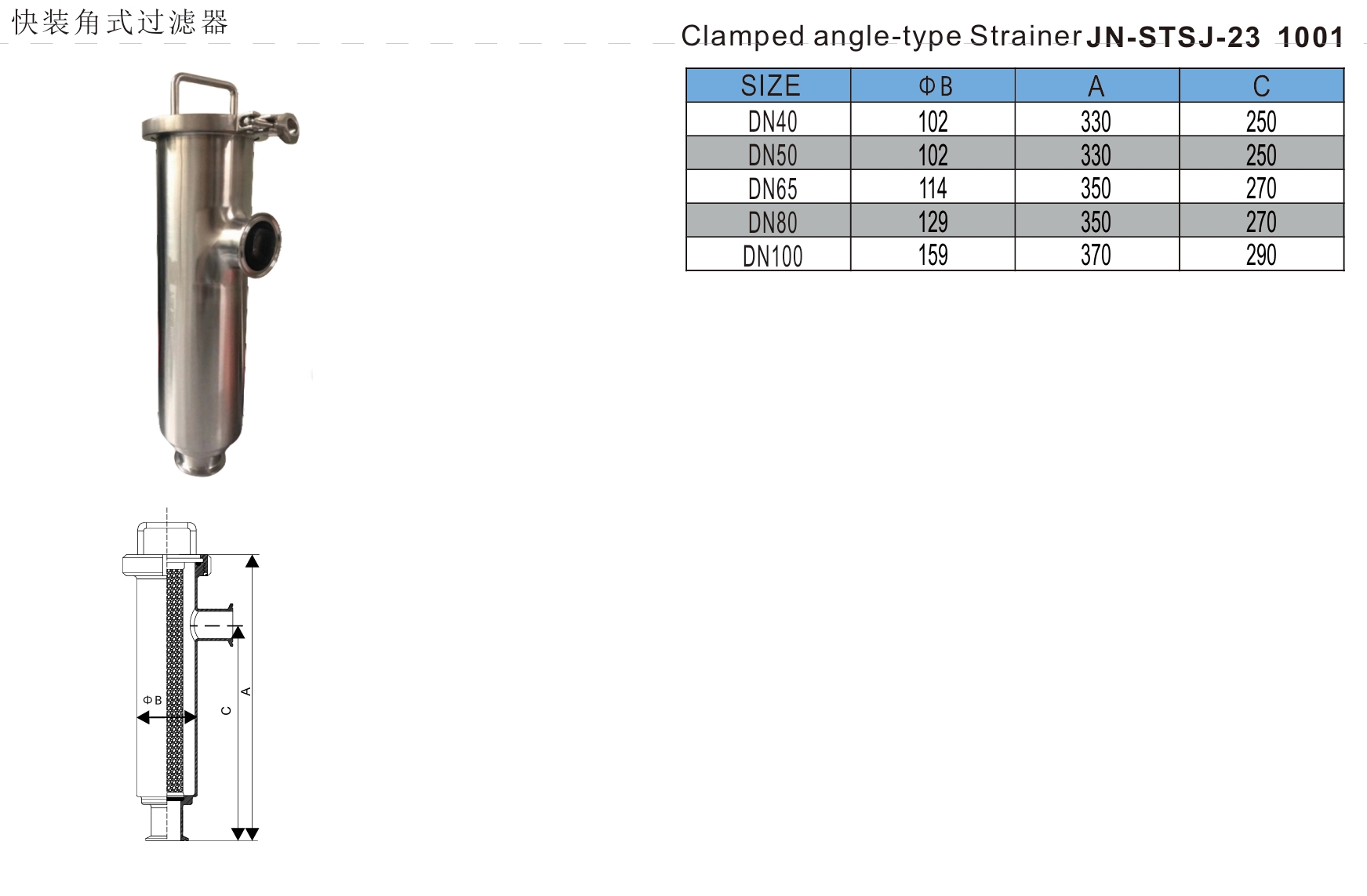

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | Silicone, EPDM, Viton, PTFE |

End connection | sanitary clamp, butt weld,threaded, union... |

Standard | 3A, DIN, SMS, ISO |

Mesh size | from 0.5mm to 2.0mm |

Screen | from 20 mesh to 300 mesh |

Internal/External Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

Features

● The stainless steel sanitary quick-install angle filter is equipped with a high-precision filter screen, and the mesh size can be customized according to needs to ensure efficient removal of solid impurities in the liquid.

● The stainless steel sanitary quick-install angle filter adopts a modular design, and the internal filter elements and external interfaces can be flexibly replaced or cleaned. The structure is simple and easy to operate.

● The internal and external flow channels of the stainless steel sanitary quick-install angle filter are optimized, which can filter efficiently without increasing the system pressure.

● The stainless steel sanitary quick-install angle filter adopts a quick-install design, which can be quickly disassembled and installed, reducing the time cost during maintenance.

● The stainless steel sanitary quick-install angle filter is equipped with a multi-layer filter screen and adjustable filtration accuracy to meet the filtering needs of impurities of different particle sizes.

● The stainless steel sanitary quick-install angle filter is designed in accordance with GMP, FDA and other hygiene standards, and all parts that contact the fluid are made of sanitary stainless steel.

Application

The industries where stainless steel sanitary quick-install angle filters are applied are mainly the following: Food processing industry: filter impurities to ensure the purity and safety of food raw materials. Pharmaceutical industry: remove fine particles to ensure the aseptic conditions of the production environment. Beverage production: filter water sources and raw materials to ensure the consistency of beverage quality. Cosmetics industry: filter raw material ingredients to ensure product quality and safety. Dairy processing: remove impurities in dairy raw materials to ensure taste and quality. Chemical industry: filter chemical raw materials to prevent impurity contamination in the reactor. Biopharmaceuticals: Remove particles from cell culture fluids to ensure drug purity.

Working Principles

The working principle of the stainless steel sanitary quick-install angle filter is based on the process of fluid passing through the filter. When the fluid enters the filter, the fluid enters the filter chamber through its angle-designed pipe, and the solid particles and impurities in the fluid are captured by the filter, while the clean fluid flows out through the mesh. The stainless steel sanitary quick-install angle filter can maintain the quality of the liquid during the production process and prevent impurities from contaminating or damaging subsequent equipment or processes. This filter also has convenient cleaning and maintenance functions, which reduces downtime in production and improves the overall operating efficiency of the equipment.

The options of the stainless steel sanitary quick-install angle filter include:

Filter mesh aperture: filter meshes with different apertures can be selected according to needs.

Drain valve: automatic or manual drain function can be selected.

Material: 304 or 316L stainless steel materials can be selected.

Sealing material: sanitary sealing materials such as EPDM and PTFE.

Interface type: different interface methods such as clamp type and quick installation type can be selected.

Filtration level: single-net or multi-net structure can be selected to meet different filtration needs.

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● The stainless steel sanitary quick-install angle filter is equipped with a high-precision filter screen, and the mesh size can be customized according to needs to ensure efficient removal of solid impurities in the liquid.

● The stainless steel sanitary quick-install angle filter adopts a modular design, and the internal filter elements and external interfaces can be flexibly replaced or cleaned. The structure is simple and easy to operate.

● The internal and external flow channels of the stainless steel sanitary quick-install angle filter are optimized, which can filter efficiently without increasing the system pressure.

● The stainless steel sanitary quick-install angle filter adopts a quick-install design, which can be quickly disassembled and installed, reducing the time cost during maintenance.

● The stainless steel sanitary quick-install angle filter is equipped with a multi-layer filter screen and adjustable filtration accuracy to meet the filtering needs of impurities of different particle sizes.

● The stainless steel sanitary quick-install angle filter is designed in accordance with GMP, FDA and other hygiene standards, and all parts that contact the fluid are made of sanitary stainless steel.

Application

The industries where stainless steel sanitary quick-install angle filters are applied are mainly the following: Food processing industry: filter impurities to ensure the purity and safety of food raw materials. Pharmaceutical industry: remove fine particles to ensure the aseptic conditions of the production environment. Beverage production: filter water sources and raw materials to ensure the consistency of beverage quality. Cosmetics industry: filter raw material ingredients to ensure product quality and safety. Dairy processing: remove impurities in dairy raw materials to ensure taste and quality. Chemical industry: filter chemical raw materials to prevent impurity contamination in the reactor. Biopharmaceuticals: Remove particles from cell culture fluids to ensure drug purity.