| Availability: | |

|---|---|

| Quantity: | |

JONENG

8481804090

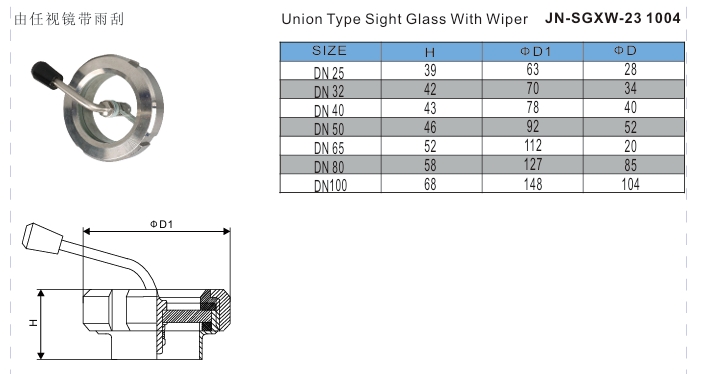

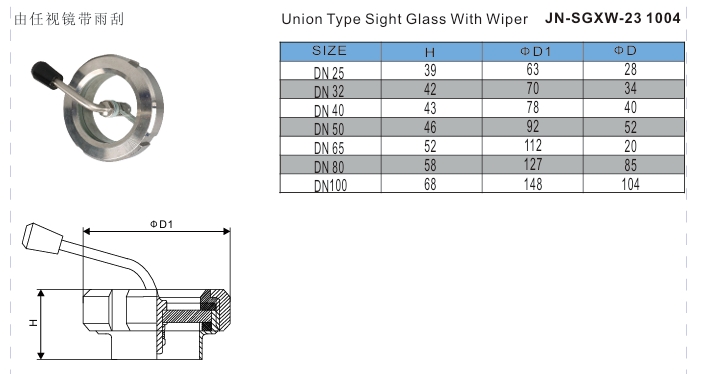

Stainless Steel Sanitary Flange Sight Glass With Brush

The stainless steel sanitary flange with brush sight glass is designed to provide efficient fluid monitoring and self-cleaning functions, solving the problem that traditional sight glasses are easily affected by dirt or impurities. The built-in brush can automatically clean the mirror surface during the operation of the pipeline, avoiding the operator from being unable to accurately observe the fluid status due to dirty mirror surface. This design not only improves the accuracy of visual monitoring, but also ensures the hygiene of the pipeline system in long-term use. It is especially suitable for industries such as food, pharmaceuticals and bioengineering, ensuring the transparency and pollution-free nature of the fluid delivery process. The flange connection method of the sight glass makes it easier to install, can meet the high cleanliness standards of the pipeline system, reduces the cumbersome steps of disassembly required for cleaning traditional sight glasses, and improves the efficiency and safety of the production line.

Working Principles

The working principle of the stainless steel sanitary flange with brush sight glass is based on fluid monitoring and self-cleaning mechanism. First, the fluid flows into the sight glass assembly through the pipeline, and the operator observes the state and flow of the fluid in the pipeline through the sight glass to ensure that the process meets the standards. At the same time, the built-in brush design of the sight glass can automatically clean the mirror surface during the flow of the fluid to prevent impurities or bubbles in the fluid from adhering to the sight glass and affecting the observation effect. The brush is usually made of elastic material and can move slightly when in contact with the fluid in the pipeline to ensure that the mirror surface remains clean. In addition, the flange connection method ensures the tight connection between the sight glass and the pipeline system, can withstand the pressure and temperature changes in the pipeline, and ensures the stability and hygiene of the system.

The options for stainless steel sanitary flange with brush sight glass include:

Material: 304 or 316 stainless steel, 316 has better corrosion resistance.

Sight glass: tempered glass, quartz glass or double-layer glass, with different temperature and pressure resistance.

Flange standards: DIN, SMS, ISO, 3A, etc., to meet different connection requirements.

Surface treatment: polishing, brushing or passivation to meet hygiene and aesthetic requirements.

Sealing material: EPDM, silicone, PTFE, etc., to adapt to different media and temperatures.

Brush material: stainless steel wire or nylon brush, used to clean the sight glass surface.

Size: a variety of diameters and lengths to match different pipe or equipment specifications.

Specification Chart

Size | 1” to 6” |

End connections | Sanitary clamp, butt-weld, i-line or others on request. |

Guard | polycarbonate guard (protects from being broken or damaged) |

Seal material | PTFE, silicone,EPDM |

Studs and Nuts | AISI 304 |

| Flange | AISI304, AISI 316L |

Pressure | - up to 10 bar |

Temperature | - up to 250 F. |

Features

● The brush inside the stainless steel sanitary flange brush sight glass can automatically adjust the cleaning force according to the flow rate. It automatically adjusts the contact force between the brush and the mirror according to the viscosity and flow rate of the fluid to avoid unnecessary wear and excessive cleaning.

● The stainless steel sanitary flange brush sight glass is equipped with a built-in heating device to prevent frost or condensation on the mirror surface in a low temperature environment from affecting the observation effect.

● The mirror surface of the stainless steel sanitary flange brush sight glass is coated with an anti-UV coating to effectively prevent ultraviolet rays from aging the mirror material.

● The mirror surface of the stainless steel sanitary flange brush sight glass is made of high-strength, impact-resistant composite materials that can withstand high-pressure shock or external force impact.

● The stainless steel sanitary flange brush sight glass design allows 360-degree rotation and can be adjusted to different angles to meet a variety of installation requirements.

● The stainless steel sanitary flange brush sight glass has a built-in pressure compensation device to automatically adjust the mirror pressure to prevent pressure fluctuations from affecting observation.

Application

Stainless steel sanitary pressure reducing valves are widely used in the following industries: Food industry: ensure fluid quality and monitor cleanliness during production. Pharmaceutical industry: monitor fluid flow and meet high cleanliness standards and hygiene requirements. Bioengineering: monitor the flow state of important fluids to ensure a clean experimental environment. Beverage industry: ensure that fluids in beverage production lines are free of contamination and meet hygiene standards. Chemical industry: monitor the flow of chemical fluids to prevent contamination and ensure safe production. Dairy industry: maintain fluid hygiene to ensure that the dairy production process is free of contamination. Water treatment industry: monitor water flow to ensure a clean and stable water treatment process.

Working Principles

The working principle of the stainless steel sanitary flange with brush sight glass is based on fluid monitoring and self-cleaning mechanism. First, the fluid flows into the sight glass assembly through the pipeline, and the operator observes the state and flow of the fluid in the pipeline through the sight glass to ensure that the process meets the standards. At the same time, the built-in brush design of the sight glass can automatically clean the mirror surface during the flow of the fluid to prevent impurities or bubbles in the fluid from adhering to the sight glass and affecting the observation effect. The brush is usually made of elastic material and can move slightly when in contact with the fluid in the pipeline to ensure that the mirror surface remains clean. In addition, the flange connection method ensures the tight connection between the sight glass and the pipeline system, can withstand the pressure and temperature changes in the pipeline, and ensures the stability and hygiene of the system.

The options for stainless steel sanitary flange with brush sight glass include:

Material: 304 or 316 stainless steel, 316 has better corrosion resistance.

Sight glass: tempered glass, quartz glass or double-layer glass, with different temperature and pressure resistance.

Flange standards: DIN, SMS, ISO, 3A, etc., to meet different connection requirements.

Surface treatment: polishing, brushing or passivation to meet hygiene and aesthetic requirements.

Sealing material: EPDM, silicone, PTFE, etc., to adapt to different media and temperatures.

Brush material: stainless steel wire or nylon brush, used to clean the sight glass surface.

Size: a variety of diameters and lengths to match different pipe or equipment specifications.

Specification Chart

Size | 1” to 6” |

End connections | Sanitary clamp, butt-weld, i-line or others on request. |

Guard | polycarbonate guard (protects from being broken or damaged) |

Seal material | PTFE, silicone,EPDM |

Studs and Nuts | AISI 304 |

| Flange | AISI304, AISI 316L |

Pressure | - up to 10 bar |

Temperature | - up to 250 F. |

Features

● The brush inside the stainless steel sanitary flange brush sight glass can automatically adjust the cleaning force according to the flow rate. It automatically adjusts the contact force between the brush and the mirror according to the viscosity and flow rate of the fluid to avoid unnecessary wear and excessive cleaning.

● The stainless steel sanitary flange brush sight glass is equipped with a built-in heating device to prevent frost or condensation on the mirror surface in a low temperature environment from affecting the observation effect.

● The mirror surface of the stainless steel sanitary flange brush sight glass is coated with an anti-UV coating to effectively prevent ultraviolet rays from aging the mirror material.

● The mirror surface of the stainless steel sanitary flange brush sight glass is made of high-strength, impact-resistant composite materials that can withstand high-pressure shock or external force impact.

● The stainless steel sanitary flange brush sight glass design allows 360-degree rotation and can be adjusted to different angles to meet a variety of installation requirements.

● The stainless steel sanitary flange brush sight glass has a built-in pressure compensation device to automatically adjust the mirror pressure to prevent pressure fluctuations from affecting observation.

Application

Stainless steel sanitary pressure reducing valves are widely used in the following industries: Food industry: ensure fluid quality and monitor cleanliness during production. Pharmaceutical industry: monitor fluid flow and meet high cleanliness standards and hygiene requirements. Bioengineering: monitor the flow state of important fluids to ensure a clean experimental environment. Beverage industry: ensure that fluids in beverage production lines are free of contamination and meet hygiene standards. Chemical industry: monitor the flow of chemical fluids to prevent contamination and ensure safe production. Dairy industry: maintain fluid hygiene to ensure that the dairy production process is free of contamination. Water treatment industry: monitor water flow to ensure a clean and stable water treatment process.