| Availability: | |

|---|---|

| Quantity: | |

DIN JN-BV 1001

JONENG

8481804090

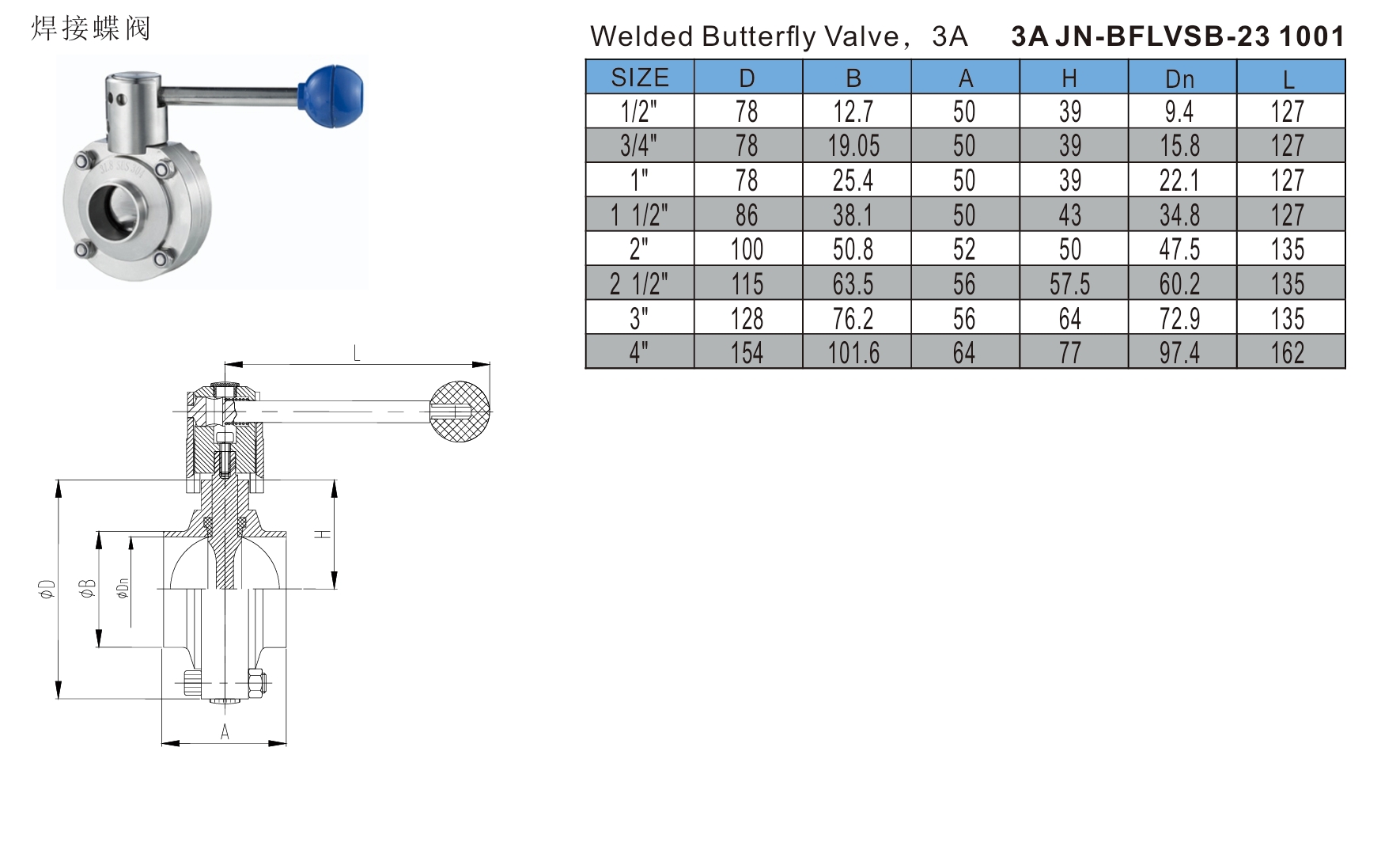

Stainless Steel Sanitary Duckbill Welding Manual Butterfly Valve

The stainless steel sanitary duckbill welded manual butterfly valve is designed to provide fluid control solutions in environments with high hygiene requirements. Its unique duckbill structure effectively avoids the retention of fluid inside the valve body, reducing the possibility of contamination sources and microbial growth. This design not only optimizes fluid flow, reduces turbulence and pressure loss, but also ensures that the valve body is easy to clean and maintain, meeting strict hygiene standards. It is particularly suitable for applications that require frequent cleaning and disinfection, such as food, beverage, pharmaceutical and other industries. It realizes fluid control while ensuring the purity and safety of the system.

Working Principles

The working principle of the stainless steel sanitary duckbill welded manual butterfly valve is based on the rotation of the butterfly plate in the valve body to control the flow of the fluid. The valve rotates the valve stem manually to gradually rotate the butterfly plate from the opening of the pipeline to form a fluid channel or completely close the pipeline. When the operating handwheel rotates, the valve stem drives the butterfly plate to rotate around its central axis. The angle adjustment of the butterfly plate determines the size of the fluid channel, thereby achieving flow regulation or closure. The structure of the stainless steel sanitary duckbill welded manual butterfly valve is simple, easy to clean and maintain, and meets the needs of frequent disinfection.

The options of the stainless steel sanitary duckbill welded manual butterfly valve include:

Material: 304 stainless steel, 316 stainless steel, etc.

Sealing material: silicone, fluororubber, EPDM, etc.

Drive mode: manual, pneumatic, electric.

Connection method: welding, clamp, threaded connection.

Butterfly plate design: full channel type, half channel type, one-way flow type, etc.

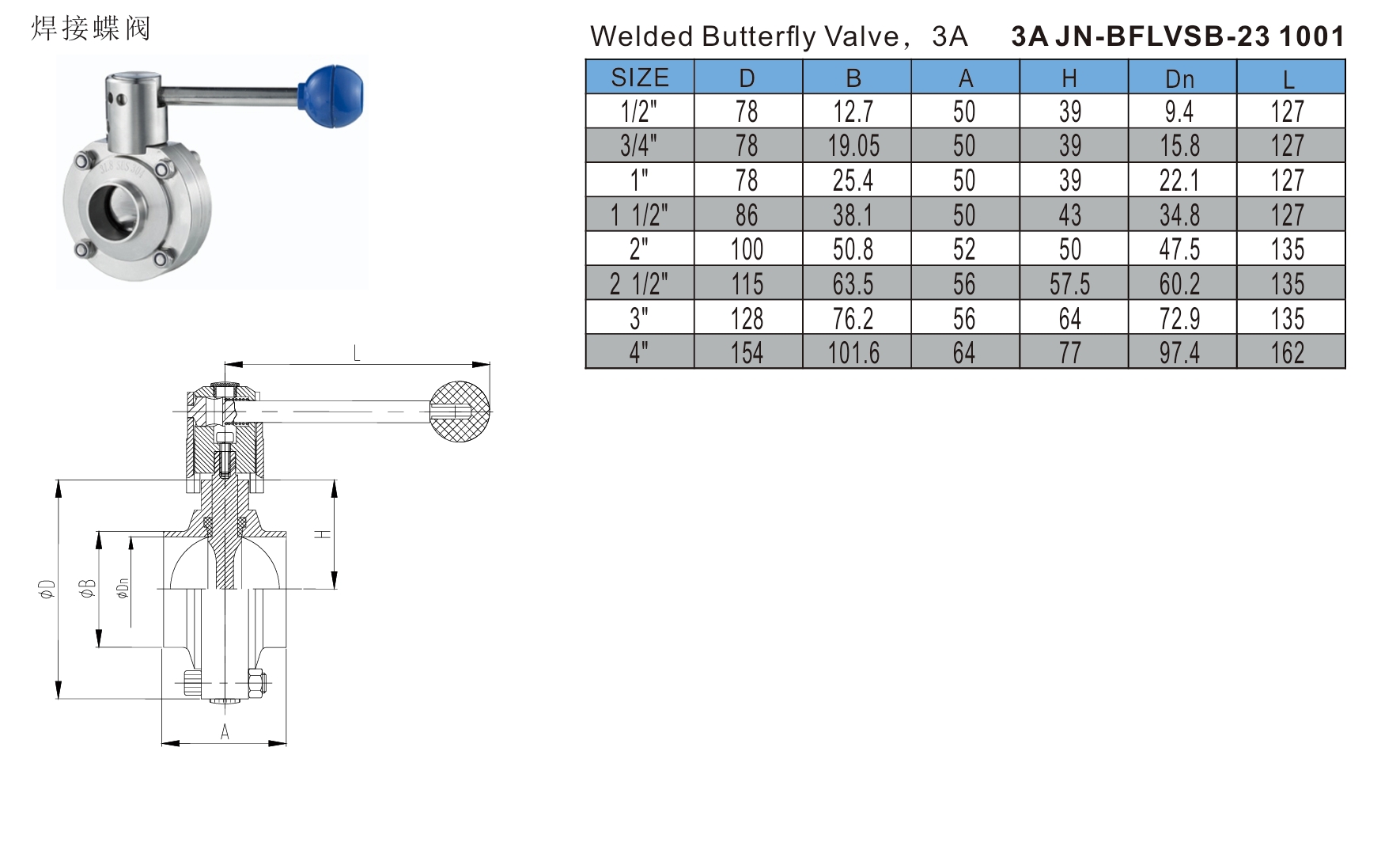

Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Valve parts

Body | Stainless steel AISI316L or AISI 304 (1.4301/1.4404) |

Disc | AISI304 or AISI316L |

Pull-position handle | Stainless Steel Material, Round type or square type |

Multi-position Gripper Handle | ABS gripper handle, SS gripper handle, 2/3/4/12 positions to adjustment, Universal type |

Gasket | EPDM, VITON(FPM), Silicone, different color is available |

Bushing | EPDM or PTFE, other material request |

Nut | Stainless Steel 304 or 316 Material or other request |

Bolt | Stainless Steel 304 or 316 Material or other request |

Features

● The stainless steel sanitary duckbill welded manual butterfly valve reduces turbulence and makes the flow smoother when the fluid flows through the valve body.

● The stainless steel sanitary duckbill welded manual butterfly valve adopts a precision stem and butterfly plate connection system, which can achieve more precise angle adjustment.

● The stainless steel sanitary duckbill welded manual butterfly valve seal ring design has adaptive ability, which can automatically adjust the sealing effect according to the temperature and pressure fluctuations during use.

● The edge of the stainless steel sanitary duckbill welded manual butterfly valve butterfly plate has been optimized to reduce the area of contact with the fluid, which helps to reduce friction and the risk of fluid contamination.

● The stainless steel sanitary duckbill welded manual butterfly valve stem system has an adjustable preload function, which can be adjusted manually.

● The stainless steel sanitary duckbill welded manual butterfly valve has a streamlined shape to reduce the resistance of the fluid flow, thereby reducing energy consumption and flow loss.

Application

Stainless steel sanitary duckbill welded manual butterfly valves are widely used in the following industries: Food industry: ensure that the fluid is pollution-free, meet hygiene standards, and ensure food safety. Beverage industry: precise flow control, prevent pollution, and ensure the quality of beverages. Pharmaceutical industry: high hygiene standards, avoid drug contamination, and ensure the safety of the production process. Cosmetics industry: prevent ingredient contamination, ensure product purity, and meet quality requirements. Chemical industry: strong corrosion resistance, control fluid flow, and avoid chemical leakage. Dairy industry: provide pollution-free fluid circulation, meet strict hygiene requirements. Water treatment industry: regulate water flow to ensure water quality and circulation efficiency.

Working Principles

The working principle of the stainless steel sanitary duckbill welded manual butterfly valve is based on the rotation of the butterfly plate in the valve body to control the flow of the fluid. The valve rotates the valve stem manually to gradually rotate the butterfly plate from the opening of the pipeline to form a fluid channel or completely close the pipeline. When the operating handwheel rotates, the valve stem drives the butterfly plate to rotate around its central axis. The angle adjustment of the butterfly plate determines the size of the fluid channel, thereby achieving flow regulation or closure. The structure of the stainless steel sanitary duckbill welded manual butterfly valve is simple, easy to clean and maintain, and meets the needs of frequent disinfection.

The options of the stainless steel sanitary duckbill welded manual butterfly valve include:

Material: 304 stainless steel, 316 stainless steel, etc.

Sealing material: silicone, fluororubber, EPDM, etc.

Drive mode: manual, pneumatic, electric.

Connection method: welding, clamp, threaded connection.

Butterfly plate design: full channel type, half channel type, one-way flow type, etc.

Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Features

● The stainless steel sanitary duckbill welded manual butterfly valve reduces turbulence and makes the flow smoother when the fluid flows through the valve body.

● The stainless steel sanitary duckbill welded manual butterfly valve adopts a precision stem and butterfly plate connection system, which can achieve more precise angle adjustment.

● The stainless steel sanitary duckbill welded manual butterfly valve seal ring design has adaptive ability, which can automatically adjust the sealing effect according to the temperature and pressure fluctuations during use.

● The edge of the stainless steel sanitary duckbill welded manual butterfly valve butterfly plate has been optimized to reduce the area of contact with the fluid, which helps to reduce friction and the risk of fluid contamination.

● The stainless steel sanitary duckbill welded manual butterfly valve stem system has an adjustable preload function, which can be adjusted manually.

● The stainless steel sanitary duckbill welded manual butterfly valve has a streamlined shape to reduce the resistance of the fluid flow, thereby reducing energy consumption and flow loss.

Application

Stainless steel sanitary duckbill welded manual butterfly valves are widely used in the following industries: Food industry: ensure that the fluid is pollution-free, meet hygiene standards, and ensure food safety. Beverage industry: precise flow control, prevent pollution, and ensure the quality of beverages. Pharmaceutical industry: high hygiene standards, avoid drug contamination, and ensure the safety of the production process. Cosmetics industry: prevent ingredient contamination, ensure product purity, and meet quality requirements. Chemical industry: strong corrosion resistance, control fluid flow, and avoid chemical leakage. Dairy industry: provide pollution-free fluid circulation, meet strict hygiene requirements. Water treatment industry: regulate water flow to ensure water quality and circulation efficiency.