| Availability: | |

|---|---|

| Quantity: | |

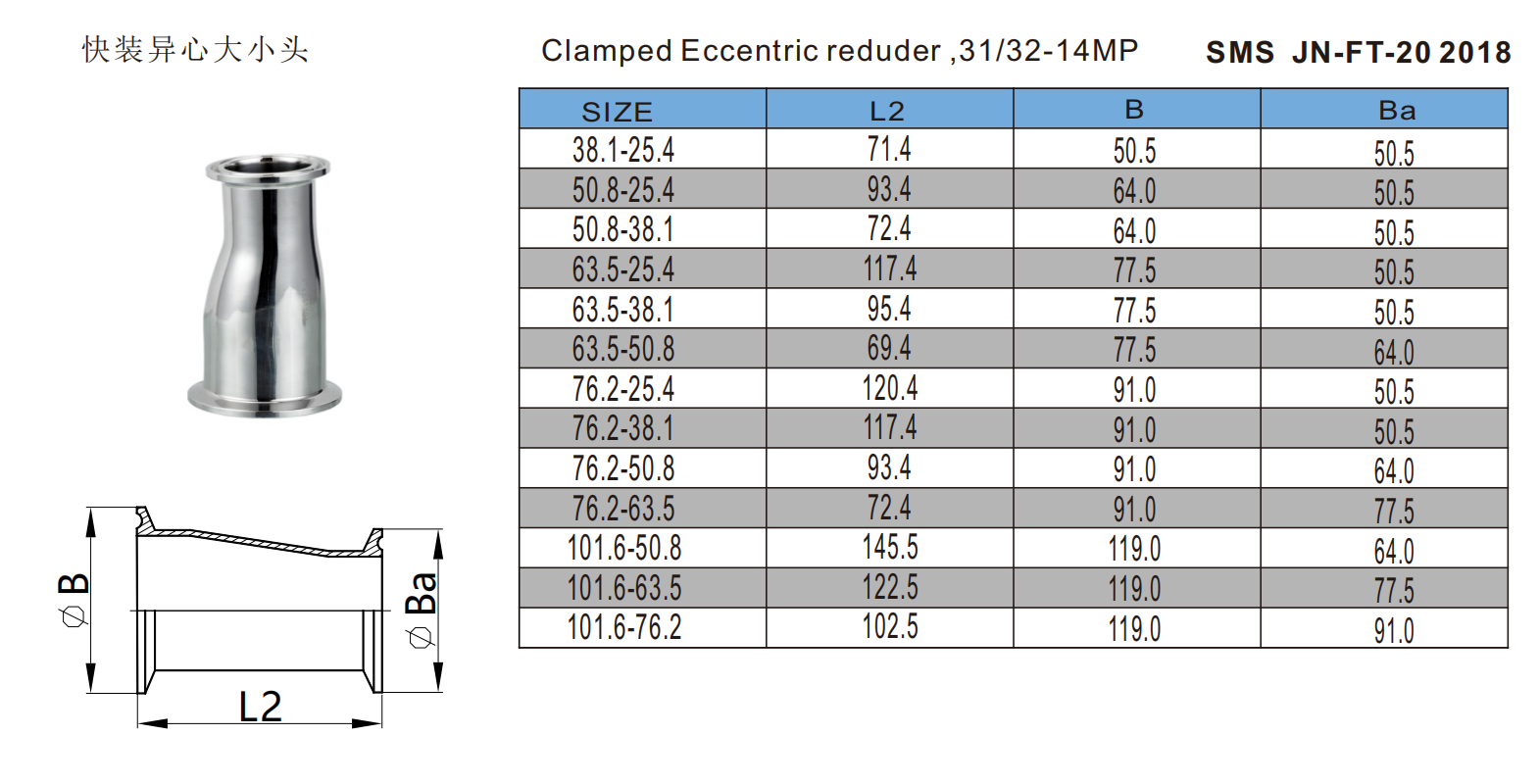

SMS JN-FT-20 2018

JONENG

7307290000

Stainless Steel Sanitary Quick-release CIP Process Eccentric Reducer

The design of the stainless steel sanitary quick-release eccentric reducer is mainly to achieve smooth and resistance-free fluid transition in the pipe system, especially in pipe connections that require diameter changes. The eccentric design ensures that the fluid will not produce unnecessary turbulence or gas accumulation due to center asymmetry when flowing, reducing the resistance of the fluid. It is widely used in pipe systems in the fields of food, pharmaceuticals, etc. to ensure smooth flow of the pipe and avoid accumulation of substances in dead corners. The quick-release structure also facilitates the rapid disassembly and assembly of the pipe, which is easy to clean and maintain, meeting the requirements of sanitary and efficient operation. Through these designs, the stainless steel quick-install eccentric reducer improves the reliability and safety of the pipeline system.

Working principle

The working principle of the stainless steel sanitary quick-install eccentric reducer is based on the quick connection design. The two ends of the eccentric reducer are connected to pipes of different sizes respectively, and the quick connection method ensures quick docking without additional tools. During installation, align the pipe port with the interface part of the eccentric reducer and fix it with a clamp or clamping device to ensure a tight connection. When the pipeline system is working, the fluid will flow from the smaller pipe to the larger pipe through the eccentric reducer, or vice versa, and the eccentric angle is used to ensure the uniform distribution of the fluid and avoid eddy currents.

The options of the stainless steel sanitary quick-install eccentric reducer include:

Material: 304 stainless steel, 316L stainless steel.

Connection method: clamp connection, welding connection.

Size specification: customized according to the size of the pipe.

Surface treatment: mirror polishing, roughness treatment.

Sealing ring material: silicone, EPDM, fluororubber.

Specification Chart

| Material | SS304, SS316L | |

| Size | 1/4''-12'' | |

| Raw material standard | ASTM A-269, A-270 | |

| Connection | Welded end, Triclover end, Male, Female, Flange | |

| Surface | Satin finish, Mirror polish, Vibrating surface, Pickled,EP, Sand Blasting | |

| Standard | 3A/SMS/DIN/ISO2037/ISO1127/AS1528/BS/BPE/IDF | |

| Certificate | ISO, PED,FDA | |

| Products Range | Elbow | 90degree elbow, 45degree elbow, 180degree elbow |

| Tee | equal tee, reducing tee | |

| Reducer | concentric reducer, eccentric reducer | |

| Application | Food, Beverage,Phamacy, Dairy | |

Features

● The stainless steel sanitary quick-install eccentric reducer adopts a precise eccentric angle design, which can effectively reduce eddy currents and bubble accumulation during fluid flow.

● The stainless steel sanitary quick-install eccentric reducer adopts an integrated molding process, which does not require welding seams, reducing the risk of leakage and stress concentration problems.

● The inner wall of the stainless steel sanitary quick-install eccentric reducer adopts mirror polishing technology, which reduces the possibility of material residue and scaling, and meets the sanitary requirements.

● The stainless steel sanitary quick-install eccentric reducer is integrated with a special sealing groove in the design to ensure that the sealing ring fits the pipeline tightly and reduces the sealing failure caused by thermal expansion.

● The design of the stainless steel sanitary quick-install eccentric reducer optimizes the path of fluid passage and improves the flow carrying capacity.

● The stainless steel sanitary quick-install eccentric reducer adopts a vibration-resistant reinforced design, which maintains the stability of the connection even in a high vibration environment.

Application

Stainless steel sanitary quick-release eccentric reducers are widely used in the following industries: Food industry: ensure smooth fluid flow and avoid accumulation of contaminants. Pharmaceutical industry: meet GMP requirements to ensure clean and sterile production lines. Beverage industry: suitable for beverage production lines with high hygiene standards. Chemical industry: strong corrosion resistance, adapt to the circulation of various chemical media. Dairy industry: ensure fluid hygiene during dairy production. Biopharmaceutical industry: accurately control fluid flow to avoid cross contamination. Cosmetics industry: ensuring high hygiene conditions in cosmetics production lines.

Working principle

The working principle of the stainless steel sanitary quick-install eccentric reducer is based on the quick connection design. The two ends of the eccentric reducer are connected to pipes of different sizes respectively, and the quick connection method ensures quick docking without additional tools. During installation, align the pipe port with the interface part of the eccentric reducer and fix it with a clamp or clamping device to ensure a tight connection. When the pipeline system is working, the fluid will flow from the smaller pipe to the larger pipe through the eccentric reducer, or vice versa, and the eccentric angle is used to ensure the uniform distribution of the fluid and avoid eddy currents.

The options of the stainless steel sanitary quick-install eccentric reducer include:

Material: 304 stainless steel, 316L stainless steel.

Connection method: clamp connection, welding connection.

Size specification: customized according to the size of the pipe.

Surface treatment: mirror polishing, roughness treatment.

Sealing ring material: silicone, EPDM, fluororubber.

Specification Chart

| Material | SS304, SS316L | |

| Size | 1/4''-12'' | |

| Raw material standard | ASTM A-269, A-270 | |

| Connection | Welded end, Triclover end, Male, Female, Flange | |

| Surface | Satin finish, Mirror polish, Vibrating surface, Pickled,EP, Sand Blasting | |

| Standard | 3A/SMS/DIN/ISO2037/ISO1127/AS1528/BS/BPE/IDF | |

| Certificate | ISO, PED,FDA | |

| Products Range | Elbow | 90degree elbow, 45degree elbow, 180degree elbow |

| Tee | equal tee, reducing tee | |

| Reducer | concentric reducer, eccentric reducer | |

| Application | Food, Beverage,Phamacy, Dairy | |

Features

● The stainless steel sanitary quick-install eccentric reducer adopts a precise eccentric angle design, which can effectively reduce eddy currents and bubble accumulation during fluid flow.

● The stainless steel sanitary quick-install eccentric reducer adopts an integrated molding process, which does not require welding seams, reducing the risk of leakage and stress concentration problems.

● The inner wall of the stainless steel sanitary quick-install eccentric reducer adopts mirror polishing technology, which reduces the possibility of material residue and scaling, and meets the sanitary requirements.

● The stainless steel sanitary quick-install eccentric reducer is integrated with a special sealing groove in the design to ensure that the sealing ring fits the pipeline tightly and reduces the sealing failure caused by thermal expansion.

● The design of the stainless steel sanitary quick-install eccentric reducer optimizes the path of fluid passage and improves the flow carrying capacity.

● The stainless steel sanitary quick-install eccentric reducer adopts a vibration-resistant reinforced design, which maintains the stability of the connection even in a high vibration environment.

Application

Stainless steel sanitary quick-release eccentric reducers are widely used in the following industries: Food industry: ensure smooth fluid flow and avoid accumulation of contaminants. Pharmaceutical industry: meet GMP requirements to ensure clean and sterile production lines. Beverage industry: suitable for beverage production lines with high hygiene standards. Chemical industry: strong corrosion resistance, adapt to the circulation of various chemical media. Dairy industry: ensure fluid hygiene during dairy production. Biopharmaceutical industry: accurately control fluid flow to avoid cross contamination. Cosmetics industry: ensuring high hygiene conditions in cosmetics production lines.