| Availability: | |

|---|---|

| Quantity: | |

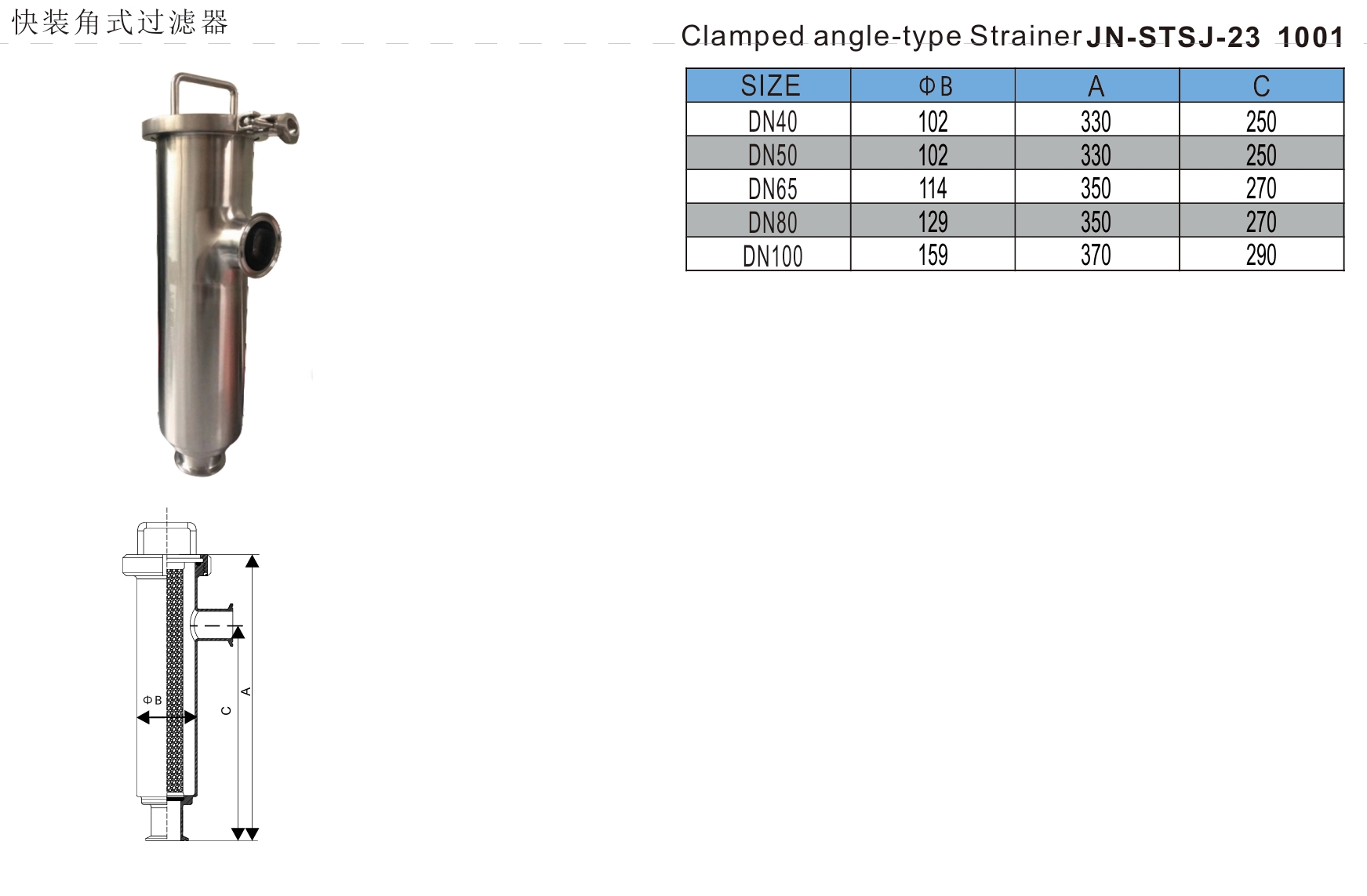

The stainless steel sanitary quick-install angle filter is a filtering device designed for high-cleanliness fluids. It is made of stainless steel, has a quick-install interface, an angle structure, a built-in precision filter, and a high-polished surface and modular design to achieve efficient filtration and convenient maintenance. The stainless steel sanitary quick-install angle filter is usually installed at the water inlet or other key parts of the pipeline system to filter impurities in the fluid. According to different application requirements and filtering functions, the stainless steel sanitary quick-install angle filter can be mainly divided into the following types: single-layer filter, multi-layer filter, automatic cleaning filter, Y-type filter, and filter with drain port.

JN-STZT-23 1010

JONENG

8421219990

Stainless Steel Sanitary High Flow Quick-install Angle Filter

The stainless steel sanitary quick-install angle filter is mainly used in the pipeline system of the food, beverage, pharmaceutical and other industries. The purpose is to filter solid particles, impurities or other contaminants in the fluid to ensure the cleanliness and hygienic safety of the fluid. Its unique angle design is easy to install, disassemble and clean, meets hygiene standards, and prevents the generation of pollution sources. Made of stainless steel, it not only has good corrosion resistance, but also ensures durability in long-term use, meets high-demand hygiene standards, and is widely used in the filtration and separation of liquids and gases.

Working Principles

The working principle of the stainless steel sanitary quick-install angle filter is based on the filtration process of the fluid through the filter screen. When the fluid enters the filter, it first enters the filter housing through the water inlet, and then the fluid passes through the filter screen in the housing, and the mesh will intercept the solid particles and impurities in the fluid. The cleaner fluid flows out through the filter screen and enters the downstream part of the pipeline system.

The options of the stainless steel sanitary quick-install angle filter include:

Filter material: 304 or 316L stainless steel.

Filter accuracy: different aperture meshes (such as 20 mesh, 40 mesh, 60 mesh, etc.).

Cleaning method: manual cleaning or automatic cleaning (backwash function).

Connection method: quick installation, welding or threaded connection.

Drainage function: whether it is equipped with a drain port.

Sealing material: rubber, silicone or PTFE.

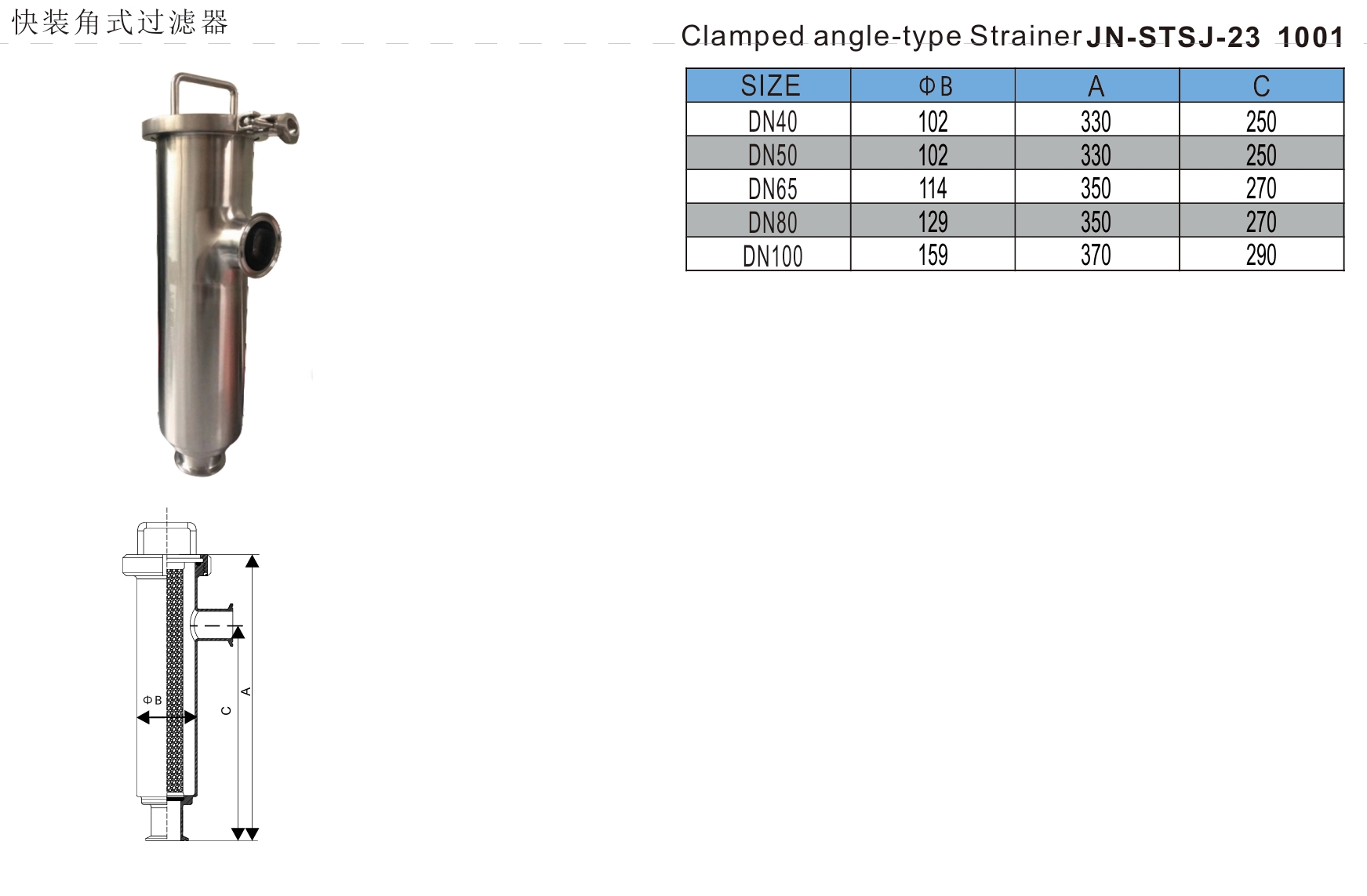

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | Silicone, EPDM, Viton, PTFE |

End connection | sanitary clamp, butt weld,threaded, union... |

Standard | 3A, DIN, SMS, ISO |

Mesh size | from 0.5mm to 2.0mm |

Screen | from 20 mesh to 300 mesh |

Internal/External Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

Features

● The stainless steel sanitary quick-install angle filter adopts a fluid vortex enhancement design, which causes the fluid to generate vortices when passing through the filter screen, thereby improving the sedimentation efficiency of particulate matter.

● The unique quick-install structure design of the stainless steel sanitary quick-install angle filter allows the filter to be quickly disassembled and cleaned, reducing maintenance and downtime.

● The stainless steel sanitary quick-install angle filter has a double-layer filter screen structure, and the inner and outer layers of the filter screen cooperate with each other to effectively improve the filtration accuracy of tiny particles.

● In addition to the internal cleaning design of the stainless steel sanitary quick-install angle filter, the outside of the filter also has a cleaning function to avoid the accumulation and pollution of external dirt.

● The internal filter screen of the stainless steel sanitary quick-install angle filter is coated with an anti-corrosion coating to effectively prevent the rapid damage of the filter screen caused by highly corrosive liquids or gases.

● The stainless steel sanitary quick-install angle filter reduces the pressure loss of the fluid during the filtration process by optimizing the fluid channel design.

Application

Stainless steel sanitary quick-install angle filters are widely used in the following industries: Food industry: beverage and dairy production filtration. Pharmaceutical industry: filtration and purification of pharmaceutical raw material liquid. Bioengineering: high-cleanliness medium filtration. Cosmetic industry: filtration of raw materials and finished products. Chemical industry: fine filtration of chemicals.

Working Principles

The working principle of the stainless steel sanitary quick-install angle filter is based on the filtration process of the fluid through the filter screen. When the fluid enters the filter, it first enters the filter housing through the water inlet, and then the fluid passes through the filter screen in the housing, and the mesh will intercept the solid particles and impurities in the fluid. The cleaner fluid flows out through the filter screen and enters the downstream part of the pipeline system.

The options of the stainless steel sanitary quick-install angle filter include:

Filter material: 304 or 316L stainless steel.

Filter accuracy: different aperture meshes (such as 20 mesh, 40 mesh, 60 mesh, etc.).

Cleaning method: manual cleaning or automatic cleaning (backwash function).

Connection method: quick installation, welding or threaded connection.

Drainage function: whether it is equipped with a drain port.

Sealing material: rubber, silicone or PTFE.

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● The stainless steel sanitary quick-install angle filter adopts a fluid vortex enhancement design, which causes the fluid to generate vortices when passing through the filter screen, thereby improving the sedimentation efficiency of particulate matter.

● The unique quick-install structure design of the stainless steel sanitary quick-install angle filter allows the filter to be quickly disassembled and cleaned, reducing maintenance and downtime.

● The stainless steel sanitary quick-install angle filter has a double-layer filter screen structure, and the inner and outer layers of the filter screen cooperate with each other to effectively improve the filtration accuracy of tiny particles.

● In addition to the internal cleaning design of the stainless steel sanitary quick-install angle filter, the outside of the filter also has a cleaning function to avoid the accumulation and pollution of external dirt.

● The internal filter screen of the stainless steel sanitary quick-install angle filter is coated with an anti-corrosion coating to effectively prevent the rapid damage of the filter screen caused by highly corrosive liquids or gases.

● The stainless steel sanitary quick-install angle filter reduces the pressure loss of the fluid during the filtration process by optimizing the fluid channel design.

Application

Stainless steel sanitary quick-install angle filters are widely used in the following industries: Food industry: beverage and dairy production filtration. Pharmaceutical industry: filtration and purification of pharmaceutical raw material liquid. Bioengineering: high-cleanliness medium filtration. Cosmetic industry: filtration of raw materials and finished products. Chemical industry: fine filtration of chemicals.