| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary angle filter is a specially designed filtering device with an angular structure. It ensures efficient filtration of impurities by diverting and evenly distributing the fluid. It effectively ensures the purity of the fluid during the production process, prevents equipment failures and product quality problems caused by pollution sources, and improves the reliability of the entire system. The stainless steel sanitary angle filter is usually used in sanitary piping systems in the food, pharmaceutical, chemical and other industries, and is installed at the fluid inlet, before the pump or at key pipeline locations. According to different design and functional requirements, the stainless steel sanitary angle filter can be divided into the following types: manual cleaning type, automatic sewage discharge type, single-layer filter type, multi-layer filter type, and adjustable filter type.

JN-STZT-23 1009

JONENG

8421219990

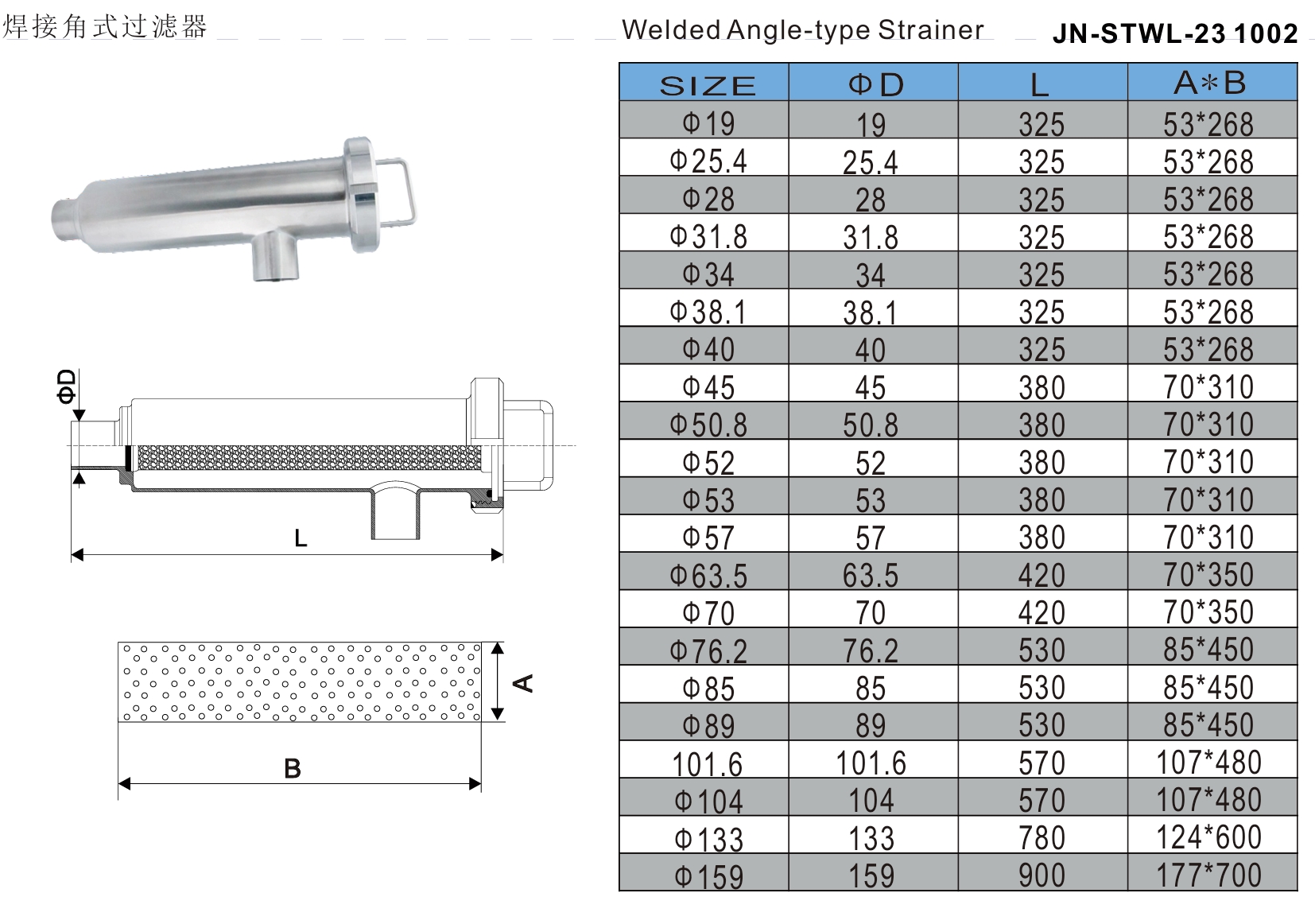

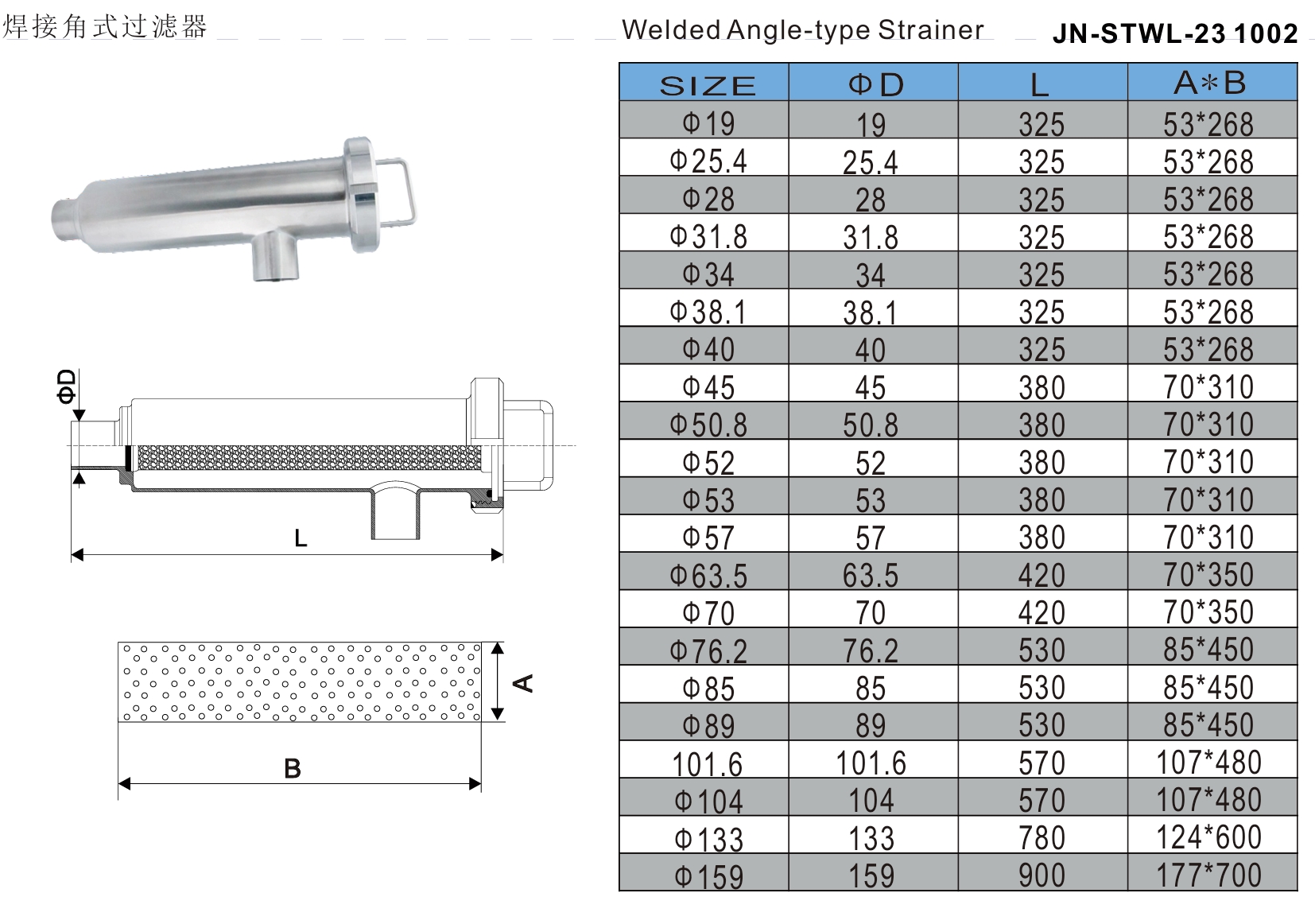

Stainless Steel Sanitary High Perfomace Welded Angle Filter Cartridge

The stainless steel sanitary angle filter is designed to effectively remove solid impurities and particulate matter from the fluid and protect the pipeline system and downstream equipment from contamination. Through the unique angular structure, it can guide the fluid to divert and evenly distribute when passing through the filter, reduce fluid turbulence, and ensure that the fluid passes through the filter at a stable and uniform speed, thereby improving the filtration efficiency. Its excellent filtering performance can meet the high hygiene standards of the food, pharmaceutical, chemical and other industries, prevent impurities in the fluid from damaging products and equipment, extend the service life of the pipeline system, and ensure the smooth production process.

Working Principles

The working principle of the stainless steel sanitary angle filter is that its unique angle design makes the fluid turn when it flows through the filter, and the solid impurities in the fluid are intercepted and isolated through the filter. After the fluid first enters the filter, it is guided by the pipe corner and flows to the filter along a special flow path. In this process, larger solid particles are physically blocked by the filter, and only clean liquid can continue to flow through the filter. The use of stainless steel sanitary angle filters can significantly improve production efficiency, product quality and system reliability, while reducing operating costs and environmental impact.

The options of stainless steel sanitary angle filters include:

Filter element accuracy: 1-200 microns are optional.

Material: 304 or 316L stainless steel.

Connection method: clamp, thread, welding.

Sealing material: silicone, fluororubber, EPDM.

Surface treatment: polishing, sandblasting.

Accessories: pressure gauge, exhaust valve.

Customized specifications: non-standard size, special interface.

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | Silicone, EPDM, Viton, PTFE |

End connection | sanitary clamp, butt weld,threaded, union... |

Standard | 3A, DIN, SMS, ISO |

Mesh size | from 0.5mm to 2.0mm |

Screen | from 20 mesh to 300 mesh |

Internal/External Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

Features

● The internal flow channel of the stainless steel sanitary angle filter adopts an asymmetric structure to reduce fluid resistance, avoid turbulence, and ensure maximum filtration efficiency.

● The surface of the stainless steel sanitary angle filter screen adopts a special coating, which can generate micro-vibration when the fluid passes through, automatically remove attached impurities, and extend the cleaning cycle.

● The inner wall of the stainless steel sanitary angle filter is nano-polished to form an ultra-smooth surface to prevent bacteria from attaching and improve hygienic performance.

● The stainless steel sanitary angle filter has a built-in micro pressure sensor to monitor the filter blockage in real time and remind maintenance through signal transmission.

● The filter element of the stainless steel sanitary angle filter can be quickly replaced, supports different precision requirements, and adapts to various process requirements without replacing the entire filter.

● The stainless steel sanitary angle filter adopts low-temperature plasma welding technology to ensure that the weld is free of cracks and pores, avoiding the risk of medium leakage.

Application

Stainless steel sanitary angle filters are used in the following industries: Food and beverage: filter liquid raw materials to ensure hygiene and safety. Pharmaceutical industry: purify liquid medicine in accordance with GMP standards. Bioengineering: separate cells and impurities to ensure purity. Cosmetics: filter raw materials to improve product quality. Dairy products: remove impurities to ensure the purity of dairy products. Chemical industry: filter corrosive media to protect equipment. Electronics industry: purify high-purity water to meet production needs. Brewing industry: filter wine to improve taste and quality.

Working Principles

The working principle of the stainless steel sanitary angle filter is that its unique angle design makes the fluid turn when it flows through the filter, and the solid impurities in the fluid are intercepted and isolated through the filter. After the fluid first enters the filter, it is guided by the pipe corner and flows to the filter along a special flow path. In this process, larger solid particles are physically blocked by the filter, and only clean liquid can continue to flow through the filter. The use of stainless steel sanitary angle filters can significantly improve production efficiency, product quality and system reliability, while reducing operating costs and environmental impact.

The options of stainless steel sanitary angle filters include:

Filter element accuracy: 1-200 microns are optional.

Material: 304 or 316L stainless steel.

Connection method: clamp, thread, welding.

Sealing material: silicone, fluororubber, EPDM.

Surface treatment: polishing, sandblasting.

Accessories: pressure gauge, exhaust valve.

Customized specifications: non-standard size, special interface.

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● The internal flow channel of the stainless steel sanitary angle filter adopts an asymmetric structure to reduce fluid resistance, avoid turbulence, and ensure maximum filtration efficiency.

● The surface of the stainless steel sanitary angle filter screen adopts a special coating, which can generate micro-vibration when the fluid passes through, automatically remove attached impurities, and extend the cleaning cycle.

● The inner wall of the stainless steel sanitary angle filter is nano-polished to form an ultra-smooth surface to prevent bacteria from attaching and improve hygienic performance.

● The stainless steel sanitary angle filter has a built-in micro pressure sensor to monitor the filter blockage in real time and remind maintenance through signal transmission.

● The filter element of the stainless steel sanitary angle filter can be quickly replaced, supports different precision requirements, and adapts to various process requirements without replacing the entire filter.

● The stainless steel sanitary angle filter adopts low-temperature plasma welding technology to ensure that the weld is free of cracks and pores, avoiding the risk of medium leakage.

Application

Stainless steel sanitary angle filters are used in the following industries: Food and beverage: filter liquid raw materials to ensure hygiene and safety. Pharmaceutical industry: purify liquid medicine in accordance with GMP standards. Bioengineering: separate cells and impurities to ensure purity. Cosmetics: filter raw materials to improve product quality. Dairy products: remove impurities to ensure the purity of dairy products. Chemical industry: filter corrosive media to protect equipment. Electronics industry: purify high-purity water to meet production needs. Brewing industry: filter wine to improve taste and quality.