| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary clamp pipe bracket is a device used for pipe support and fixation, and usually plays a role in stabilizing the pipe in the pipe system. The stainless steel sanitary clamp pipe bracket is usually used in pipe systems in the food, pharmaceutical, beverage and other industries, especially for pipes that require strict sanitary conditions. It is usually installed in the middle of the horizontal or vertical pipe section, especially at pipe connections, corners, long pipe sections or locations that are easily affected by external forces. According to the design and use requirements, the stainless steel sanitary clamp pipe bracket usually has the following types: single bracket type, double bracket type, adjustable type, hanging bracket type, and basic bracket.

JONENG

8481804090

Stainless Steel Sanitary High Performance Clamp Pipe Bracket

The design of the stainless steel sanitary clamp pipe bracket is to solve the stability and durability problems of the pipe system under high pressure, high temperature or complex environment. It uses a precise clamping structure to ensure that the pipe can effectively withstand internal and external pressures, temperature changes and vibrations during operation, thereby avoiding displacement, deformation or damage of the pipe due to uneven force or external interference. This design also ensures the convenience of installation and maintenance, and is suitable for industries with high hygiene requirements (such as food, pharmaceuticals, etc.), and optimizes the pipeline layout to improve the safety and reliability of the entire system.

Working Principles

The working principle of the stainless steel sanitary clamp pipe bracket is to firmly fix the pipe in the predetermined position through the clamping design to ensure the stability of the pipe during operation. The core is that the bracket clamps the two sides of the pipe through a pair of clamping components to form a stable support structure. These support points can not only withstand internal and external pressures, but also effectively resist the vibration of the pipe caused by fluid flow, temperature changes or external forces.

The options of the stainless steel sanitary clamp pipe bracket include:

Material options: 304, 316 stainless steel.

Size options: can be customized according to the diameter and length of the pipe.

Bracket type: single bracket, double bracket, adjustable, hanging type, etc.

Surface treatment: brushed, polished, sandblasted.

Fixation method: wall-mounted, ground-fixed.

Load capacity: adapt to different pressure and load requirements.

Installation method: bolt fixing or welding installation.

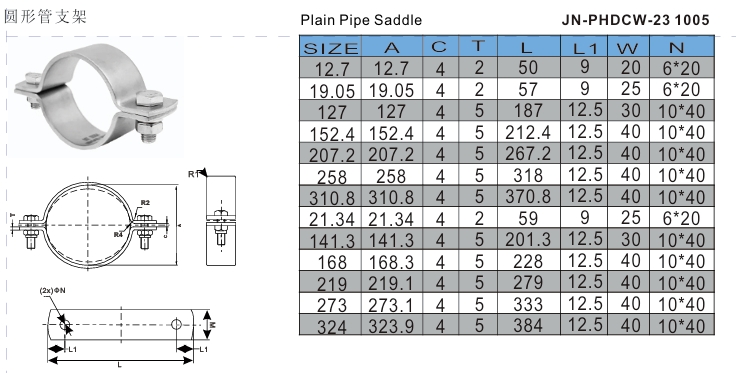

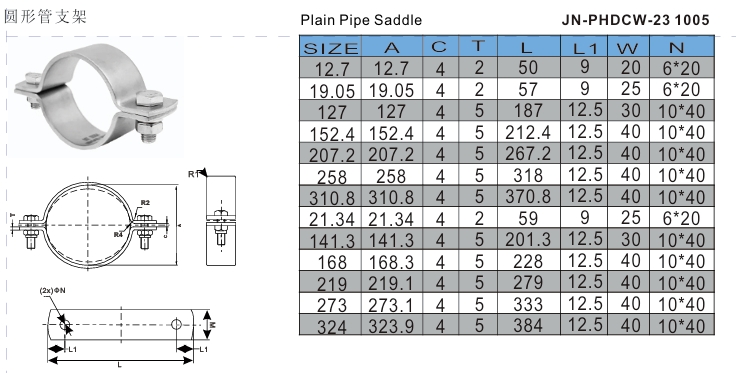

Specification Chart

Size | ½ " to 12 " |

Material | AISI 304,AISI201 |

Standard | DIN, SMS, ISO, 3A,AS,BS |

Production way | Pressed |

Made from sheets | |

Features

● The stainless steel sanitary clamp pipe bracket adopts an innovative anti-dynamic load design, which can withstand sudden impacts or variable loads in the pipeline system.

● The stainless steel sanitary clamp pipe bracket is equipped with a dynamic adjustment mechanism, which can automatically adjust according to the changes in the pipeline load to ensure that the pipeline always maintains the best support state.

● The stainless steel sanitary clamp pipe bracket adopts advanced anti-micro-vibration technology, and the bracket can effectively suppress the impact of micro-vibration on the pipeline.

● The welding part of the stainless steel sanitary clamp pipe bracket adopts seamless welding technology, which avoids the micro-cracks that may be caused by traditional welding joints and ensures the strength and sealing of the welding part.

● The surface of the stainless steel sanitary clamp pipe bracket is treated with an anti-oxidation coating, which can effectively resist oxidation and corrosion and extend the service life of the bracket. The coating not only improves corrosion resistance, but also maintains good performance in high temperature environments.

● The base of the stainless steel sanitary clamp pipe bracket is designed with an anti-slip function. The base adopts a special anti-slip material or design to ensure that the bracket can firmly withstand external pressure without moving when fixing the pipeline.

Application

Stainless steel sanitary clamp pipe brackets are widely used in the following industries: Food industry: ensure stable installation of pipelines and meet sanitary standards. Pharmaceutical industry: provide stable support to prevent pipeline displacement and meet strict standards. Beverage production: ensure the stability and cleanliness of the pipeline system and prevent pollution. Chemical industry: withstand pipeline pressure changes to ensure stable system operation. Medical industry: suitable for clean environments to protect fluids from contamination. Dairy processing: ensure pipelines are securely fixed and meet hygiene and corrosion resistance requirements. Drinking water treatment: support pipeline structures to avoid leakage and external damage.

Working Principles

The working principle of the stainless steel sanitary clamp pipe bracket is to firmly fix the pipe in the predetermined position through the clamping design to ensure the stability of the pipe during operation. The core is that the bracket clamps the two sides of the pipe through a pair of clamping components to form a stable support structure. These support points can not only withstand internal and external pressures, but also effectively resist the vibration of the pipe caused by fluid flow, temperature changes or external forces.

The options of the stainless steel sanitary clamp pipe bracket include:

Material options: 304, 316 stainless steel.

Size options: can be customized according to the diameter and length of the pipe.

Bracket type: single bracket, double bracket, adjustable, hanging type, etc.

Surface treatment: brushed, polished, sandblasted.

Fixation method: wall-mounted, ground-fixed.

Load capacity: adapt to different pressure and load requirements.

Installation method: bolt fixing or welding installation.

Specification Chart

Size | ½ " to 12 " |

Material | AISI 304,AISI201 |

Standard | DIN, SMS, ISO, 3A,AS,BS |

Production way | Pressed |

Made from sheets | |

Features

● The stainless steel sanitary clamp pipe bracket adopts an innovative anti-dynamic load design, which can withstand sudden impacts or variable loads in the pipeline system.

● The stainless steel sanitary clamp pipe bracket is equipped with a dynamic adjustment mechanism, which can automatically adjust according to the changes in the pipeline load to ensure that the pipeline always maintains the best support state.

● The stainless steel sanitary clamp pipe bracket adopts advanced anti-micro-vibration technology, and the bracket can effectively suppress the impact of micro-vibration on the pipeline.

● The welding part of the stainless steel sanitary clamp pipe bracket adopts seamless welding technology, which avoids the micro-cracks that may be caused by traditional welding joints and ensures the strength and sealing of the welding part.

● The surface of the stainless steel sanitary clamp pipe bracket is treated with an anti-oxidation coating, which can effectively resist oxidation and corrosion and extend the service life of the bracket. The coating not only improves corrosion resistance, but also maintains good performance in high temperature environments.

● The base of the stainless steel sanitary clamp pipe bracket is designed with an anti-slip function. The base adopts a special anti-slip material or design to ensure that the bracket can firmly withstand external pressure without moving when fixing the pipeline.

Application

Stainless steel sanitary clamp pipe brackets are widely used in the following industries: Food industry: ensure stable installation of pipelines and meet sanitary standards. Pharmaceutical industry: provide stable support to prevent pipeline displacement and meet strict standards. Beverage production: ensure the stability and cleanliness of the pipeline system and prevent pollution. Chemical industry: withstand pipeline pressure changes to ensure stable system operation. Medical industry: suitable for clean environments to protect fluids from contamination. Dairy processing: ensure pipelines are securely fixed and meet hygiene and corrosion resistance requirements. Drinking water treatment: support pipeline structures to avoid leakage and external damage.