| Availability: | |

|---|---|

| Quantity: | |

JONENG

8481804090

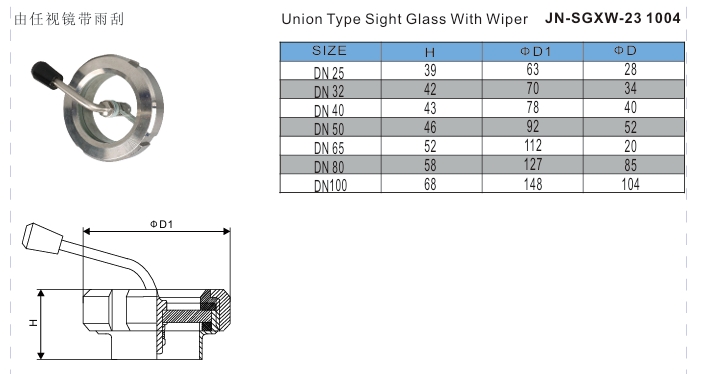

Stainless Steel Sanitary Manual Flange Sight Glass With Brush

The stainless steel sanitary manual brush flange sight glass is designed to provide a clear observation window in the pipeline system while ensuring operation under high hygiene standards. The sight glass integrates a flange connection, which is convenient for close connection with the pipeline system to ensure sealing. The design of the manual brush function allows operators to easily clean the surface of the sight glass during the observation process to avoid unclear observation due to dirt or liquid residue. This sight glass is particularly suitable for fluid flow monitoring, which can help production line workers check changes in fluid status, color, bubbles, etc. in real time and find problems in time. Its design meets the hygiene standards of the food, pharmaceutical, beverage and other industries, prevents cross contamination, ensures the quality and safety of products, especially in demanding production environments, to ensure the cleanliness of equipment and the non-contamination of fluids.

Working Principles

The working principle of the stainless steel sanitary manual brush flange sight glass is based on the sealing of the flange connection and the observation function of the sight glass window. When the sight glass is installed on the pipeline, the fluid flows through the pipeline, and the operator can observe the fluid state in the pipeline through the sight glass. The surface of the sight glass is equipped with a brush, and the user can manually operate the brush to clean the surface of the sight glass to avoid dirt or fluid residue affecting the observation field of view. The brush removes impurities on the sight glass by rotating or moving, ensuring that the observation window always remains transparent and provides a clear view. The flange connection of the sight glass ensures the tight closure of the equipment, prevents fluid leakage, and ensures hygiene requirements.

The options for stainless steel sanitary manual brush flange sight glass include:

Sight glass window shape: round, square

Material selection: stainless steel 304, 316L

Flange standard: DIN, ANSI, SMS, etc.

Brush material: stainless steel brush, nylon brush

Dimensions: suitable for different pipe diameters

Cleaning method: manual cleaning, automatic cleaning options

Seal material: EPDM, PTFE, etc.

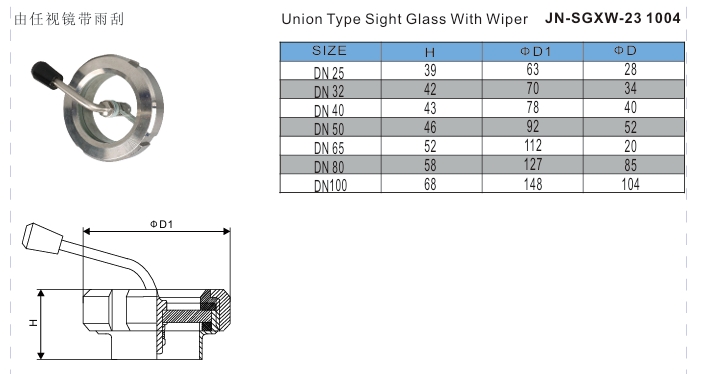

Specification Chart

Size | 1” to 6” |

End connections | Sanitary clamp, butt-weld, i-line or others on request. |

Guard | polycarbonate guard (protects from being broken or damaged) |

Seal material | PTFE, silicone,EPDM |

Studs and Nuts | AISI 304 |

| Flange | AISI304, AISI 316L |

Pressure | - up to 10 bar |

Temperature | - up to 250 F. |

Features

● The brush inside the stainless steel sanitary manual brush flange sight glass has a bidirectional rotation function, which can be rotated clockwise or counterclockwise to clean the mirror surface as needed.

● The stainless steel sanitary manual brush flange sight glass is designed with a dead zone flow channel to ensure that impurities will not be retained or deposited in any part when the fluid passes through the sight glass.

● The stainless steel sanitary manual brush flange sight glass uses a special material window with anti-fog function, which can keep the window clear even in high humidity or large temperature difference environment.

● The stainless steel sanitary manual brush flange sight glass is designed with an integrated temperature sensor inside, which can monitor the temperature changes of the fluid in the pipeline in real time.

● The stainless steel sanitary manual brush flange sight glass is equipped with an automatic sewage discharge system, which automatically cleans the impurities accumulated on the surface of the sight glass or in the pipeline through the flow of fluid.

● The stainless steel sanitary manual brush flange sight glass is designed with a quick disassembly function, and the operator can easily disassemble the sight glass for maintenance or cleaning without tools.

Application

Stainless steel sanitary manual brush flange mirrors are widely used in the following industries: Food and beverage: real-time monitoring of pipeline fluids to ensure production hygiene and safety. Pharmaceutical industry: GMP certification process observation to eliminate cross contamination. Bioengineering: Visualization of the fermentation process to precisely control quality. Dairy processing: CIP cleaning verification to ensure the purity of dairy products. Cosmetics industry: Raw material status detection to maintain product stability. Semiconductor industry: High-purity medium observation to meet clean room standards.

Working Principles

The working principle of the stainless steel sanitary manual brush flange sight glass is based on the sealing of the flange connection and the observation function of the sight glass window. When the sight glass is installed on the pipeline, the fluid flows through the pipeline, and the operator can observe the fluid state in the pipeline through the sight glass. The surface of the sight glass is equipped with a brush, and the user can manually operate the brush to clean the surface of the sight glass to avoid dirt or fluid residue affecting the observation field of view. The brush removes impurities on the sight glass by rotating or moving, ensuring that the observation window always remains transparent and provides a clear view. The flange connection of the sight glass ensures the tight closure of the equipment, prevents fluid leakage, and ensures hygiene requirements.

The options for stainless steel sanitary manual brush flange sight glass include:

Sight glass window shape: round, square

Material selection: stainless steel 304, 316L

Flange standard: DIN, ANSI, SMS, etc.

Brush material: stainless steel brush, nylon brush

Dimensions: suitable for different pipe diameters

Cleaning method: manual cleaning, automatic cleaning options

Seal material: EPDM, PTFE, etc.

Specification Chart

Size | 1” to 6” |

End connections | Sanitary clamp, butt-weld, i-line or others on request. |

Guard | polycarbonate guard (protects from being broken or damaged) |

Seal material | PTFE, silicone,EPDM |

Studs and Nuts | AISI 304 |

| Flange | AISI304, AISI 316L |

Pressure | - up to 10 bar |

Temperature | - up to 250 F. |

Features

● The brush inside the stainless steel sanitary manual brush flange sight glass has a bidirectional rotation function, which can be rotated clockwise or counterclockwise to clean the mirror surface as needed.

● The stainless steel sanitary manual brush flange sight glass is designed with a dead zone flow channel to ensure that impurities will not be retained or deposited in any part when the fluid passes through the sight glass.

● The stainless steel sanitary manual brush flange sight glass uses a special material window with anti-fog function, which can keep the window clear even in high humidity or large temperature difference environment.

● The stainless steel sanitary manual brush flange sight glass is designed with an integrated temperature sensor inside, which can monitor the temperature changes of the fluid in the pipeline in real time.

● The stainless steel sanitary manual brush flange sight glass is equipped with an automatic sewage discharge system, which automatically cleans the impurities accumulated on the surface of the sight glass or in the pipeline through the flow of fluid.

● The stainless steel sanitary manual brush flange sight glass is designed with a quick disassembly function, and the operator can easily disassemble the sight glass for maintenance or cleaning without tools.

Application

Stainless steel sanitary manual brush flange mirrors are widely used in the following industries: Food and beverage: real-time monitoring of pipeline fluids to ensure production hygiene and safety. Pharmaceutical industry: GMP certification process observation to eliminate cross contamination. Bioengineering: Visualization of the fermentation process to precisely control quality. Dairy processing: CIP cleaning verification to ensure the purity of dairy products. Cosmetics industry: Raw material status detection to maintain product stability. Semiconductor industry: High-purity medium observation to meet clean room standards.