| Availability: | |

|---|---|

| Quantity: | |

JONENG

8481804090

Stainless Steel Sanitary Mirror Polished Fixture Sight Glass

The stainless steel sanitary mirror polished fixture sight glass is designed to achieve visual monitoring of the fluid status in the pipeline in an environment with high requirements for hygiene and sterility. Its mirror polished surface reduces the risk of bacteria and impurities by reducing the attachment of microorganisms, while also reducing the cumbersome steps in the cleaning process. In addition, the mirror design can provide extremely high clarity, helping operators to monitor the flow, color, bubbles and other subtle changes of the fluid in real time, timely detect problems in the pipeline, and avoid potential contamination or quality problems in the production process. This kind of sight glass is particularly suitable for sensitive production lines that need to finely monitor the flow of fluids and prevent cross contamination, ensuring the hygiene standards and quality control of products.

Working Principles

The working principle of the stainless steel sanitary mirror polished fixture sight glass is based on optical visualization technology. When the fluid passes through the pipeline, the mirror polished surface of the sight glass provides a clear reflection, allowing the operator to observe the flow state of the fluid in the pipeline through a transparent window. The sight glass is usually equipped with a sealing ring to ensure that the fluid does not leak and provide additional stability. Some sight glasses have built-in lights, which can provide additional lighting to help observe in low-light environments.

Options for stainless steel sanitary mirror polished fixture sight glasses include:

Lighting function: optional built-in LED lights to provide visualization support in dark environments.

Cleaning function: optional automatic cleaning system to keep the mirror clean.

Temperature and pressure levels: different temperature and pressure adaptation ranges, selected according to working conditions.

Installation method: welding, ferrule or threaded connection are optional.

Mirror window material: glass or polycarbonate can be selected to meet different application requirements.

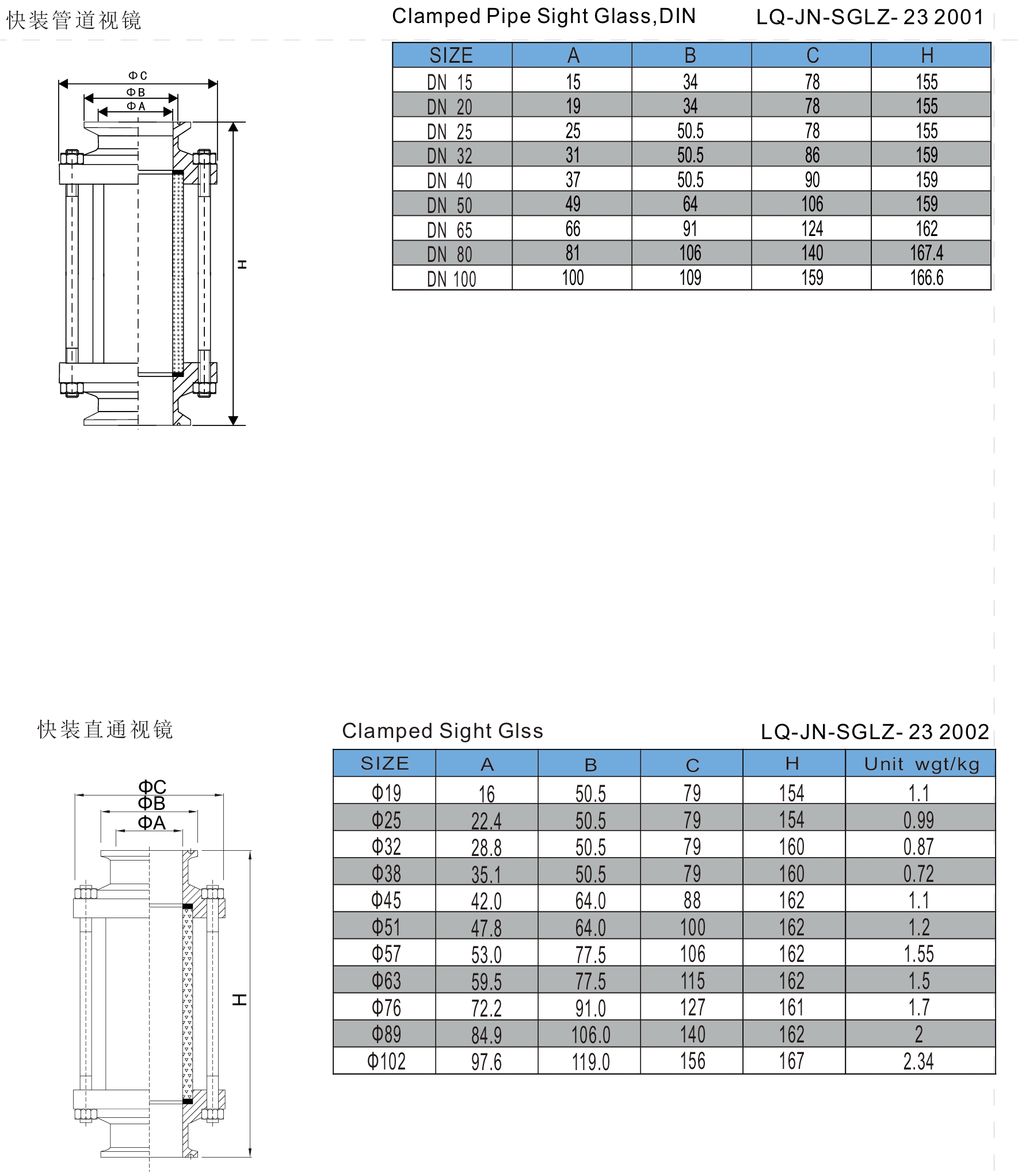

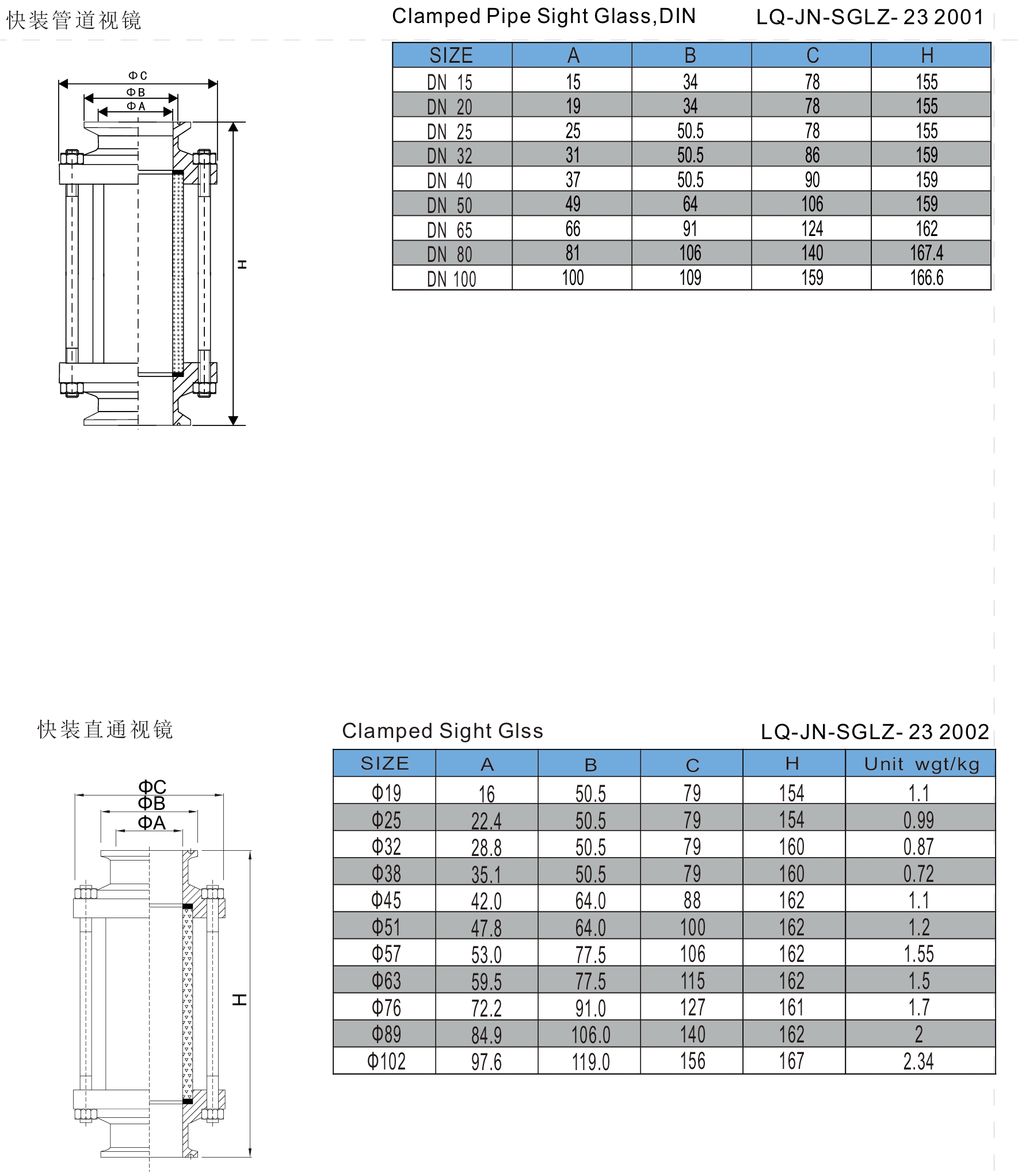

Specification Chart

Size | 1” to 6” |

End connections | Sanitary clamp, butt-weld, i-line or others on request. |

Guard | polycarbonate guard (protects from being broken or damaged) |

Seal material | PTFE, silicone,EPDM |

Studs and Nuts | AISI 304 |

| Flange | AISI304, AISI 316L |

Pressure | - up to 10 bar |

Temperature | - up to 250 F. |

Features

● The stainless steel sanitary mirror polished fixture sight glass adopts microstructure optimization surface treatment technology to ensure that the mirror surface has extremely low surface roughness and reduce resistance and deposition in fluid flow.

● The stainless steel sanitary mirror polished fixture sight glass is equipped with a dynamic pressure response seal ring, which can automatically adjust the sealing strength according to the pipeline pressure to ensure that the sight glass can maintain stable sealing under different working conditions.

● The stainless steel sanitary mirror polished fixture sight glass has a built-in intelligent temperature control system, which can automatically adjust the working temperature to avoid material aging or structural damage caused by high temperature.

● The stainless steel sanitary mirror polished fixture sight glass adopts a high-precision fluid monitoring window design, which improves fluid visibility through a special optical coating, and can clearly observe the flow state even in highly turbid fluids.

● The material and sealing system of the stainless steel sanitary mirror polished fixture sight glass have been specially treated to maintain good toughness and sealing in low temperature environments.

● The stainless steel sanitary mirror polished fixture sight glass adopts anti-ultraviolet radiation coating technology to prevent ultraviolet rays from damaging the material and internal structure.

Application

Stainless steel sanitary mirror polished fixture sight glasses are widely used in the following industries: Food processing industry: used in the production process of milk, juice, sauce, beverage, etc. to observe the fluid state in real time to ensure product quality and hygiene standards. Dairy industry: monitor the flow state of liquids such as milk and yogurt in pasteurization, fermentation, filling and other links to prevent contamination and quality abnormalities. Pharmaceutical industry: suitable for aseptic conveying pipelines to ensure visual monitoring of high-clean fluids such as liquid medicine and injection to prevent cross contamination. Biotechnology industry: in vaccines, culture media, bioreactors and other processes, provide precise fluid monitoring to ensure a sterile environment and production stability. Beer and beverage industry: used in the filtration, fermentation, mixing and other processes of the production line to ensure the uniformity of the fluid and the controllability of the production process.

Working Principles

The working principle of the stainless steel sanitary mirror polished fixture sight glass is based on optical visualization technology. When the fluid passes through the pipeline, the mirror polished surface of the sight glass provides a clear reflection, allowing the operator to observe the flow state of the fluid in the pipeline through a transparent window. The sight glass is usually equipped with a sealing ring to ensure that the fluid does not leak and provide additional stability. Some sight glasses have built-in lights, which can provide additional lighting to help observe in low-light environments.

Options for stainless steel sanitary mirror polished fixture sight glasses include:

Lighting function: optional built-in LED lights to provide visualization support in dark environments.

Cleaning function: optional automatic cleaning system to keep the mirror clean.

Temperature and pressure levels: different temperature and pressure adaptation ranges, selected according to working conditions.

Installation method: welding, ferrule or threaded connection are optional.

Mirror window material: glass or polycarbonate can be selected to meet different application requirements.

Specification Chart

Size | 1” to 6” |

End connections | Sanitary clamp, butt-weld, i-line or others on request. |

Guard | polycarbonate guard (protects from being broken or damaged) |

Seal material | PTFE, silicone,EPDM |

Studs and Nuts | AISI 304 |

| Flange | AISI304, AISI 316L |

Pressure | - up to 10 bar |

Temperature | - up to 250 F. |

Features

● The stainless steel sanitary mirror polished fixture sight glass adopts microstructure optimization surface treatment technology to ensure that the mirror surface has extremely low surface roughness and reduce resistance and deposition in fluid flow.

● The stainless steel sanitary mirror polished fixture sight glass is equipped with a dynamic pressure response seal ring, which can automatically adjust the sealing strength according to the pipeline pressure to ensure that the sight glass can maintain stable sealing under different working conditions.

● The stainless steel sanitary mirror polished fixture sight glass has a built-in intelligent temperature control system, which can automatically adjust the working temperature to avoid material aging or structural damage caused by high temperature.

● The stainless steel sanitary mirror polished fixture sight glass adopts a high-precision fluid monitoring window design, which improves fluid visibility through a special optical coating, and can clearly observe the flow state even in highly turbid fluids.

● The material and sealing system of the stainless steel sanitary mirror polished fixture sight glass have been specially treated to maintain good toughness and sealing in low temperature environments.

● The stainless steel sanitary mirror polished fixture sight glass adopts anti-ultraviolet radiation coating technology to prevent ultraviolet rays from damaging the material and internal structure.

Application

Stainless steel sanitary mirror polished fixture sight glasses are widely used in the following industries: Food processing industry: used in the production process of milk, juice, sauce, beverage, etc. to observe the fluid state in real time to ensure product quality and hygiene standards. Dairy industry: monitor the flow state of liquids such as milk and yogurt in pasteurization, fermentation, filling and other links to prevent contamination and quality abnormalities. Pharmaceutical industry: suitable for aseptic conveying pipelines to ensure visual monitoring of high-clean fluids such as liquid medicine and injection to prevent cross contamination. Biotechnology industry: in vaccines, culture media, bioreactors and other processes, provide precise fluid monitoring to ensure a sterile environment and production stability. Beer and beverage industry: used in the filtration, fermentation, mixing and other processes of the production line to ensure the uniformity of the fluid and the controllability of the production process.