| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary straight-through filter is a filtering device designed for pipeline systems with high sanitation requirements. It is usually used to filter impurities, particles and microorganisms in liquids. The stainless steel sanitary straight-through filter is mainly used in sanitary pipeline systems in the food, pharmaceutical, cosmetic and beverage industries. It is usually installed at the water inlet of the pipeline or the key node of fluid delivery, such as before the pump, at the junction of the pipeline or where the filtration demand is high. There are mainly the following types of stainless steel sanitary clamp filters: Y-type straight-through filter, T-type straight-through filter, cylindrical straight-through filter, and filter mesh straight-through filter.

JN-STJY-23 1001

JONENG

8421219990

Stainless Steel Sanitary Single Filter Clamp Filter For Pharmaceutical Use

The stainless steel sanitary straight-through filter is designed to meet the requirements of strict hygiene standards. It removes impurities, particles and microorganisms in the fluid through an efficient filtration system to ensure the cleanliness of the fluid during the production process and avoid contamination and cross-infection. In addition, the clamp connection design enables the filter to maintain high efficiency under frequent cleaning and maintenance. This design not only improves the filtration efficiency, but also shortens the cleaning and replacement time, greatly reducing production downtime. Through high-precision filters and easy-to-disassemble structures, it can ensure the stability of the fluid delivery system in a high-hygiene environment, meet the requirements of strict standards such as GMP, and improve product quality and production efficiency.

Working Principles

The working principle of the stainless steel sanitary straight-through filter is based on the physical filtration process of the fluid passing through the filter. First, the fluid enters the filter from the pipeline and is introduced into the filter through the pipe interface connected by the clamp. Then, the fluid passes through the built-in filter or filter element, and solid impurities, particulate matter and microorganisms are effectively intercepted, while the clean fluid continues to flow through the outlet of the filter. According to the design of the filter, the pore size of the filter can be selected according to different application requirements to ensure the removal of different types of impurities.

The options of the stainless steel sanitary straight-through filter include:

Filter material: stainless steel, plastic

Filter accuracy: different mesh sizes (20μm, 50μm, 100μm, etc.)

Connection method: clamp type, flange type

Cleaning method: manual cleaning, automatic cleaning

Size: according to the pipe diameter (DN15-DN150, etc.)

Filter form: single filter element, multiple filter elements

Gasket material: silicone, EPDM, Viton

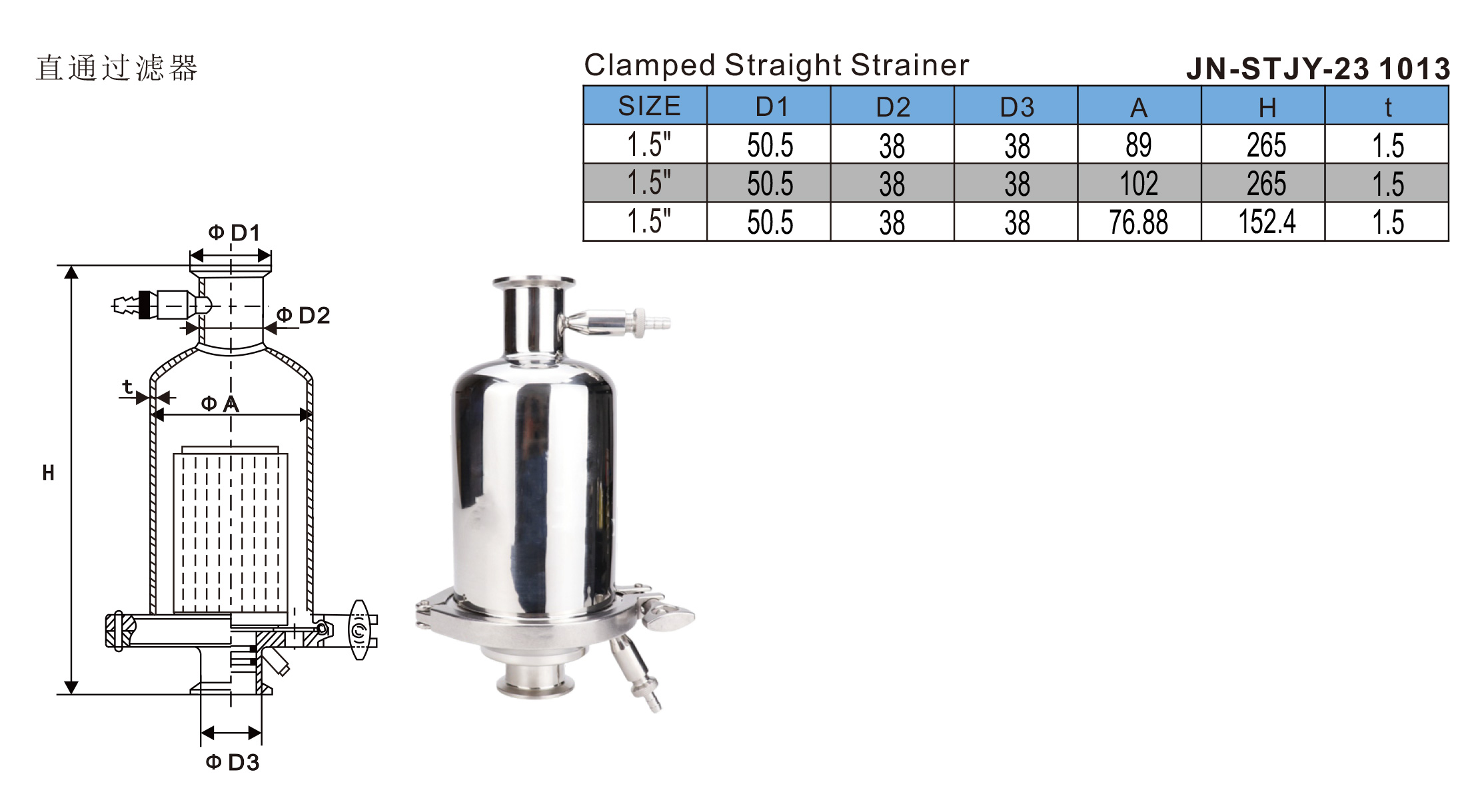

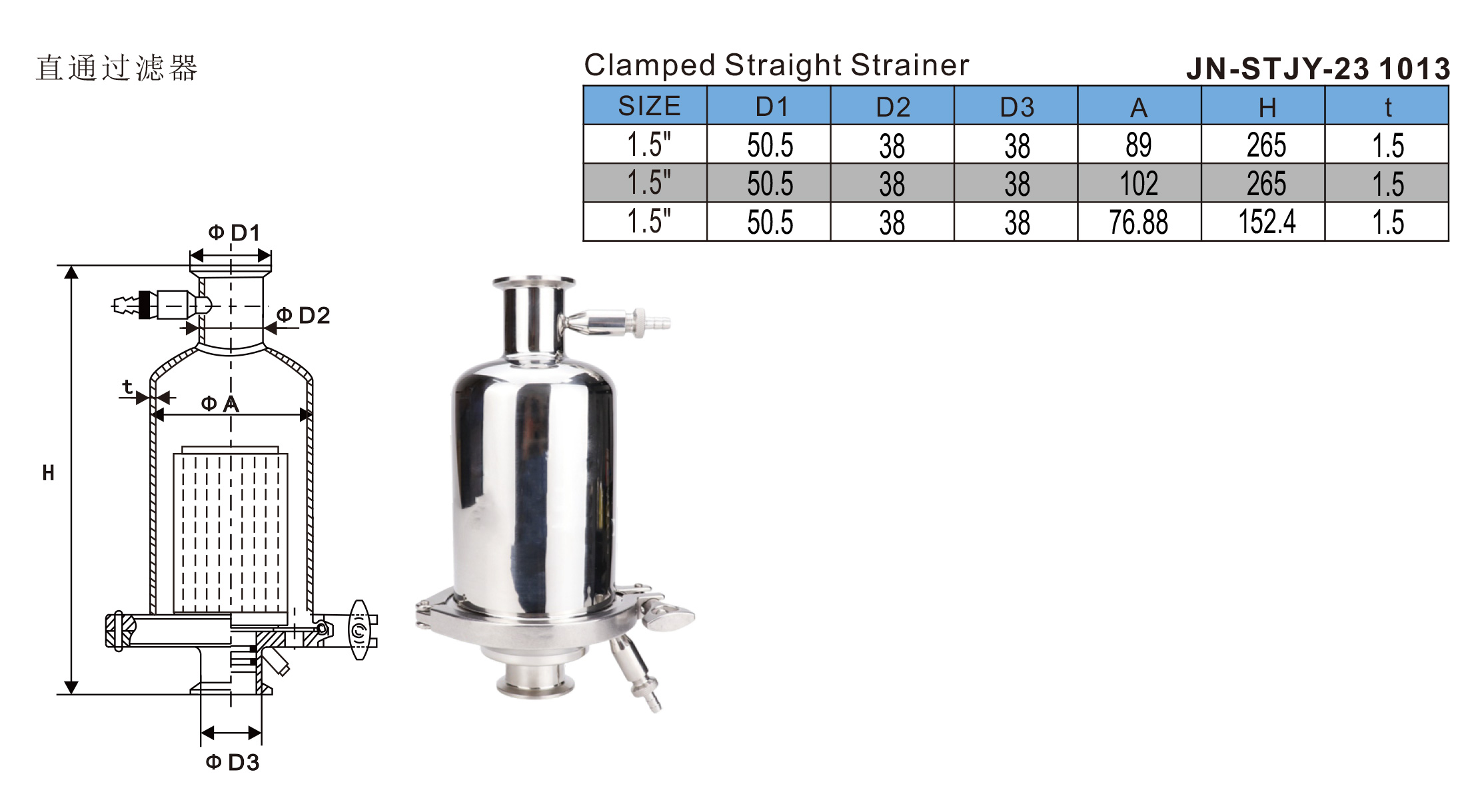

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● The stainless steel sanitary straight-through filter adopts multi-layer stainless steel fiber sintering technology, and the pore size decreases layer by layer from the outside to the inside, forming a gradient filtration structure, which effectively intercepts particles of different particle sizes and avoids rapid blockage caused by a single pore size.

● The stainless steel sanitary straight-through filter is equipped with a spiral guide groove inside the filter. When the fluid passes through, a vortex effect is generated, which automatically flushes the surface of the filter element, reduces particle adhesion, and extends the cleaning cycle.

● The force-bearing surface of the stainless steel sanitary straight-through filter clamp adopts an asymmetric design with an oblique angle, which generates radial and axial double clamping forces when locked, ensuring uniform deformation of the sealing gasket and eliminating side leakage.

● The stainless steel sanitary straight-through filter generates a dense chromium oxide film on the surface of 316L stainless steel through electrochemical passivation, and the thickness is controlled at the nanometer level, which not only improves corrosion resistance, but also avoids the microscopic roughness caused by traditional pickling.

● The stainless steel sanitary straight-through filter has a pre-buried micro pressure sensor interface inside the filter housing, which can monitor the pressure difference before and after the filter element in real time. The data is transmitted to the control system wirelessly to achieve predictive maintenance.

● The stainless steel sanitary straight-through filter adopts pulse plasma arc welding under inert gas protection, and the heat-affected zone of the weld is extremely narrow, which avoids the formation of intergranular corrosion sensitive areas.

Application

Stainless steel sanitary straight-through filters are widely used in the following industries: Food industry: used to support the pipeline system during food production to ensure the hygiene and safety of the food production process. Pharmaceutical industry: used to support the pipeline of drug production to ensure that the production environment meets GMP standards and prevent pollution. Cosmetics industry: support the pipeline system of cosmetics production to ensure that there is no pollution during fluid transportation. Beverage industry: ensure the stability of the beverage production pipeline system and meet food safety standards.

Working Principles

The working principle of the stainless steel sanitary straight-through filter is based on the physical filtration process of the fluid passing through the filter. First, the fluid enters the filter from the pipeline and is introduced into the filter through the pipe interface connected by the clamp. Then, the fluid passes through the built-in filter or filter element, and solid impurities, particulate matter and microorganisms are effectively intercepted, while the clean fluid continues to flow through the outlet of the filter. According to the design of the filter, the pore size of the filter can be selected according to different application requirements to ensure the removal of different types of impurities.

The options of the stainless steel sanitary straight-through filter include:

Filter material: stainless steel, plastic

Filter accuracy: different mesh sizes (20μm, 50μm, 100μm, etc.)

Connection method: clamp type, flange type

Cleaning method: manual cleaning, automatic cleaning

Size: according to the pipe diameter (DN15-DN150, etc.)

Filter form: single filter element, multiple filter elements

Gasket material: silicone, EPDM, Viton

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● The stainless steel sanitary straight-through filter adopts multi-layer stainless steel fiber sintering technology, and the pore size decreases layer by layer from the outside to the inside, forming a gradient filtration structure, which effectively intercepts particles of different particle sizes and avoids rapid blockage caused by a single pore size.

● The stainless steel sanitary straight-through filter is equipped with a spiral guide groove inside the filter. When the fluid passes through, a vortex effect is generated, which automatically flushes the surface of the filter element, reduces particle adhesion, and extends the cleaning cycle.

● The force-bearing surface of the stainless steel sanitary straight-through filter clamp adopts an asymmetric design with an oblique angle, which generates radial and axial double clamping forces when locked, ensuring uniform deformation of the sealing gasket and eliminating side leakage.

● The stainless steel sanitary straight-through filter generates a dense chromium oxide film on the surface of 316L stainless steel through electrochemical passivation, and the thickness is controlled at the nanometer level, which not only improves corrosion resistance, but also avoids the microscopic roughness caused by traditional pickling.

● The stainless steel sanitary straight-through filter has a pre-buried micro pressure sensor interface inside the filter housing, which can monitor the pressure difference before and after the filter element in real time. The data is transmitted to the control system wirelessly to achieve predictive maintenance.

● The stainless steel sanitary straight-through filter adopts pulse plasma arc welding under inert gas protection, and the heat-affected zone of the weld is extremely narrow, which avoids the formation of intergranular corrosion sensitive areas.

Application

Stainless steel sanitary straight-through filters are widely used in the following industries: Food industry: used to support the pipeline system during food production to ensure the hygiene and safety of the food production process. Pharmaceutical industry: used to support the pipeline of drug production to ensure that the production environment meets GMP standards and prevent pollution. Cosmetics industry: support the pipeline system of cosmetics production to ensure that there is no pollution during fluid transportation. Beverage industry: ensure the stability of the beverage production pipeline system and meet food safety standards.