| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary T-type filter is installed in the pipeline system to intercept and remove impurities or particles in the liquid to ensure the cleanliness of the fluid. The stainless steel sanitary T-type filter is usually installed at the front end of the sanitary process pipeline of food, beverage, pharmaceutical, etc. or in front of key equipment, such as pumps, valves, heat exchangers or filling machine inlets, to intercept particulate impurities in the liquid, protect downstream equipment, and ensure the cleanliness of the fluid and safe operation of the equipment during the production process. The common types of stainless steel sanitary T-type filters are mainly the following: quick-install T-type filter, welded T-type filter, threaded T-type filter, flange T-type filter.

JN-STZT-23 1010

JONENG

8421219990

Stainless Steel Sanitary T-type Filter For Water Treatment Industry

The stainless steel sanitary T-type filter is designed to ensure the purity and safety of the fluid in industries with extremely high cleanliness requirements. Its main purpose is to filter out particulate impurities, sediments or tiny foreign matter in the liquid to prevent these impurities from entering the subsequent production links, affecting product quality or damaging equipment. The T-type structure design is easy to install in the pipeline system without affecting the normal flow of the liquid. At the same time, the filter element is easy to disassemble and clean, which improves maintenance efficiency. The filter adopts a sanitary design, with a smooth interior and no dead corners, which meets the CIP/SIP cleaning requirements, can effectively prevent bacterial growth, and ensure that the entire process meets the sanitary standards.

Working Principles

The working principle of the stainless steel sanitary T-type filter is: when the liquid medium flows into the filter from the pipeline, it first enters the filter cavity, and the fluid is guided through the internal stainless steel filter or filter element. In the process of the liquid passing through the filter, impurities, particles or suspended matter are intercepted on the surface or inside of the filter, and only clean liquid is allowed to pass, thereby achieving preliminary purification. The filtered liquid continues to flow from the filter outlet to the downstream equipment. As impurities gradually accumulate, the filtering capacity of the filter will weaken, so the filter element needs to be removed regularly for cleaning or replacement.

The options for stainless steel sanitary T-type filters include:

Connection methods: quick-install, welding, thread, flange

Filter accuracy: 10μm, 50μm, 100μm, etc. are available

Filter material: wire mesh, sintered mesh, wedge mesh

Surface treatment: internal and external polishing, mirror polishing, electrolytic polishing

Drain design: optional with or without drain outlet

Pressure level: standard or high pressure

Installation direction: horizontal or vertical installation

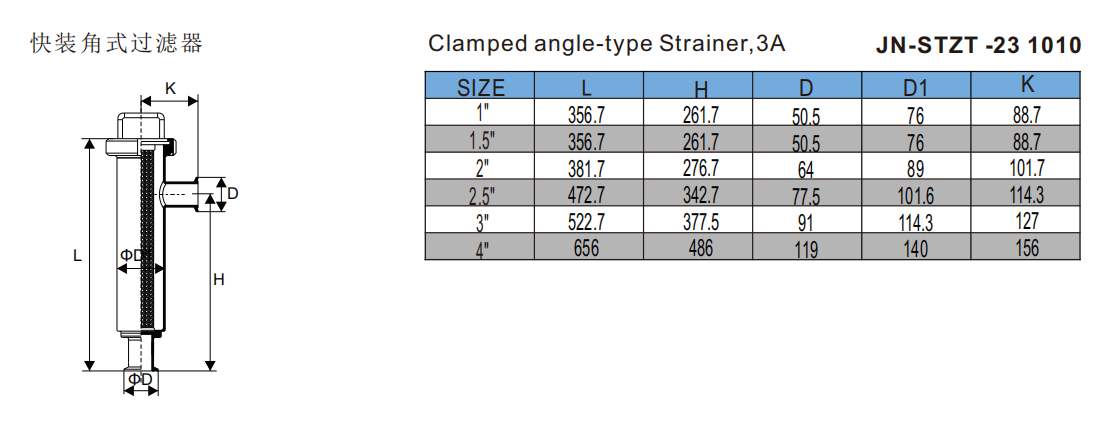

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | Silicone, EPDM, Viton, PTFE |

End connection | sanitary clamp, butt weld,threaded, union... |

Standard | 3A, DIN, SMS, ISO |

Mesh size | from 0.5mm to 2.0mm |

Screen | from 20 mesh to 300 mesh |

Internal/External Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

Features

● The stainless steel sanitary T-type filter is equipped with a slot or a limit ring inside, which can automatically locate the filter position, prevent the filter from shifting due to fluid impact, and ensure stable filtering accuracy.

● The inner wall of the stainless steel sanitary T-type filter is mirror-polished and matched with a large rounded transition structure, which effectively avoids dead corners and reduces material residues. It is suitable for processes with extremely high cleanliness.

● A small buffer chamber is provided at the inlet of the stainless steel sanitary T-type filter, which can disperse the instantaneous impact force of the fluid, protect the filter from being damaged by the impact of high-pressure fluid, and extend the service life.

● The filter element of the stainless steel sanitary T-type filter adopts a segmented assembly structure, which can be quickly replaced with multiple sections in parallel or in series according to flow requirements to improve the filtering area and accuracy.

● The liquid outlet of the stainless steel sanitary T-type filter is designed as a rotatable structure, which can adjust the liquid outlet direction according to the on-site installation direction, which is convenient for installation and saves space.

● The stainless steel sanitary T-type filter housing is preset with a pressure gauge or sensor installation position, which can be used to install a pressure monitoring system later to achieve online monitoring of the degree of blockage.

Application

Stainless steel sanitary T-type filters are widely used in the following industries: Food and beverage industry: used to filter liquid raw materials to ensure hygiene and safety. Pharmaceutical industry: purify liquid medicines in accordance with GMP aseptic requirements. Cosmetics industry: Filter essences, etc. to ensure product purity. Water treatment industry: Purify drinking water and remove particulate impurities. Chemical industry: Treat corrosive media, acid, alkali and high temperature resistance. Bioengineering: Filter cell culture fluid to maintain a sterile environment. Electronics industry: Prepare ultrapure water to prevent particulate contamination.

Working Principles

The working principle of the stainless steel sanitary T-type filter is: when the liquid medium flows into the filter from the pipeline, it first enters the filter cavity, and the fluid is guided through the internal stainless steel filter or filter element. In the process of the liquid passing through the filter, impurities, particles or suspended matter are intercepted on the surface or inside of the filter, and only clean liquid is allowed to pass, thereby achieving preliminary purification. The filtered liquid continues to flow from the filter outlet to the downstream equipment. As impurities gradually accumulate, the filtering capacity of the filter will weaken, so the filter element needs to be removed regularly for cleaning or replacement.

The options for stainless steel sanitary T-type filters include:

Connection methods: quick-install, welding, thread, flange

Filter accuracy: 10μm, 50μm, 100μm, etc. are available

Filter material: wire mesh, sintered mesh, wedge mesh

Surface treatment: internal and external polishing, mirror polishing, electrolytic polishing

Drain design: optional with or without drain outlet

Pressure level: standard or high pressure

Installation direction: horizontal or vertical installation

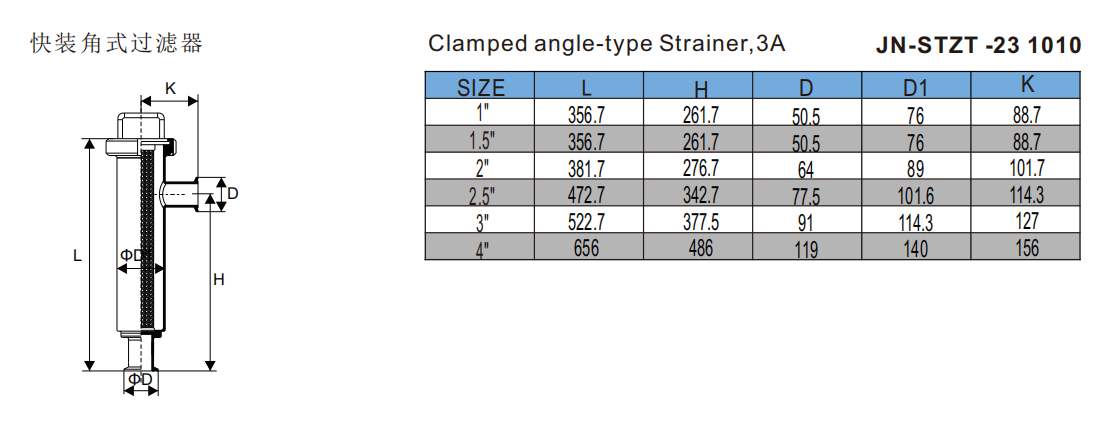

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● The stainless steel sanitary T-type filter is equipped with a slot or a limit ring inside, which can automatically locate the filter position, prevent the filter from shifting due to fluid impact, and ensure stable filtering accuracy.

● The inner wall of the stainless steel sanitary T-type filter is mirror-polished and matched with a large rounded transition structure, which effectively avoids dead corners and reduces material residues. It is suitable for processes with extremely high cleanliness.

● A small buffer chamber is provided at the inlet of the stainless steel sanitary T-type filter, which can disperse the instantaneous impact force of the fluid, protect the filter from being damaged by the impact of high-pressure fluid, and extend the service life.

● The filter element of the stainless steel sanitary T-type filter adopts a segmented assembly structure, which can be quickly replaced with multiple sections in parallel or in series according to flow requirements to improve the filtering area and accuracy.

● The liquid outlet of the stainless steel sanitary T-type filter is designed as a rotatable structure, which can adjust the liquid outlet direction according to the on-site installation direction, which is convenient for installation and saves space.

● The stainless steel sanitary T-type filter housing is preset with a pressure gauge or sensor installation position, which can be used to install a pressure monitoring system later to achieve online monitoring of the degree of blockage.

Application

Stainless steel sanitary T-type filters are widely used in the following industries: Food and beverage industry: used to filter liquid raw materials to ensure hygiene and safety. Pharmaceutical industry: purify liquid medicines in accordance with GMP aseptic requirements. Cosmetics industry: Filter essences, etc. to ensure product purity. Water treatment industry: Purify drinking water and remove particulate impurities. Chemical industry: Treat corrosive media, acid, alkali and high temperature resistance. Bioengineering: Filter cell culture fluid to maintain a sterile environment. Electronics industry: Prepare ultrapure water to prevent particulate contamination.