| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary angle filter is a filtering device designed for pipeline systems. Its unique structure makes the liquid flow rate unaffected and provides stable filtering performance. The stainless steel sanitary angle filter is mainly used at the inlet or outlet position of the liquid or gas pipeline system. It is usually installed at the water inlet or feed end of the pipeline to filter impurities, particles or precipitation in the fluid to ensure the normal operation of downstream equipment and the cleanliness of the fluid. Common types of stainless steel sanitary angle filters include: Y-type filter, T-type filter, basket filter, spiral filter, automatic cleaning filter.

JN-STJY-23 1001

JONENG

8421219990

Stainless Steel Sanitary Tri Clamp Automatic Cleaning Single Angle Filter

The purpose of the stainless steel sanitary angle filter design is to improve the stability and long-term reliability of the fluid system. Through its unique angle structure, it can effectively isolate and remove impurities such as solid particles and sediments in the fluid without affecting the flow rate and pressure, thereby protecting the pipeline and other equipment from damage by pollutants. This design is particularly suitable for environments with limited space, easy to install and maintain, ensuring the hygiene and efficient operation of the entire system, and suitable for industries with high cleanliness requirements, such as pharmaceuticals, food processing, etc.

Working Principles

The working principle of the stainless steel sanitary angle filter is based on the principle of physical filtration, and the solid impurities in the fluid are intercepted by the filter or screen inside it. The fluid first enters the filter, passes through the inlet pipe of the filter, and enters the filter cavity. When the fluid flows through the filter, larger particulate matter is intercepted by the filter, and the purified fluid flows out smoothly through the outlet. The pore size of the filter can be selected according to needs to meet the requirements of different filtration accuracy. When impurities accumulate to a certain extent, clean or replace the filter to ensure the filtration effect. This process does not require external force and is completely driven by the pressure of the fluid.

The options for stainless steel sanitary angle filters include:

Filter material: stainless steel, ceramic, nylon and other materials can be selected.

Filter accuracy: Filters with different pore sizes (such as 20μm, 50μm, 100μm, etc.) can be selected according to needs.

Cleaning method: manual cleaning or automatic cleaning.

Connection method: quick-install, flange, threaded, etc.

Flow size: filter adapted to different flow requirements.

Dimensions: select the appropriate size and design according to the pipeline space.

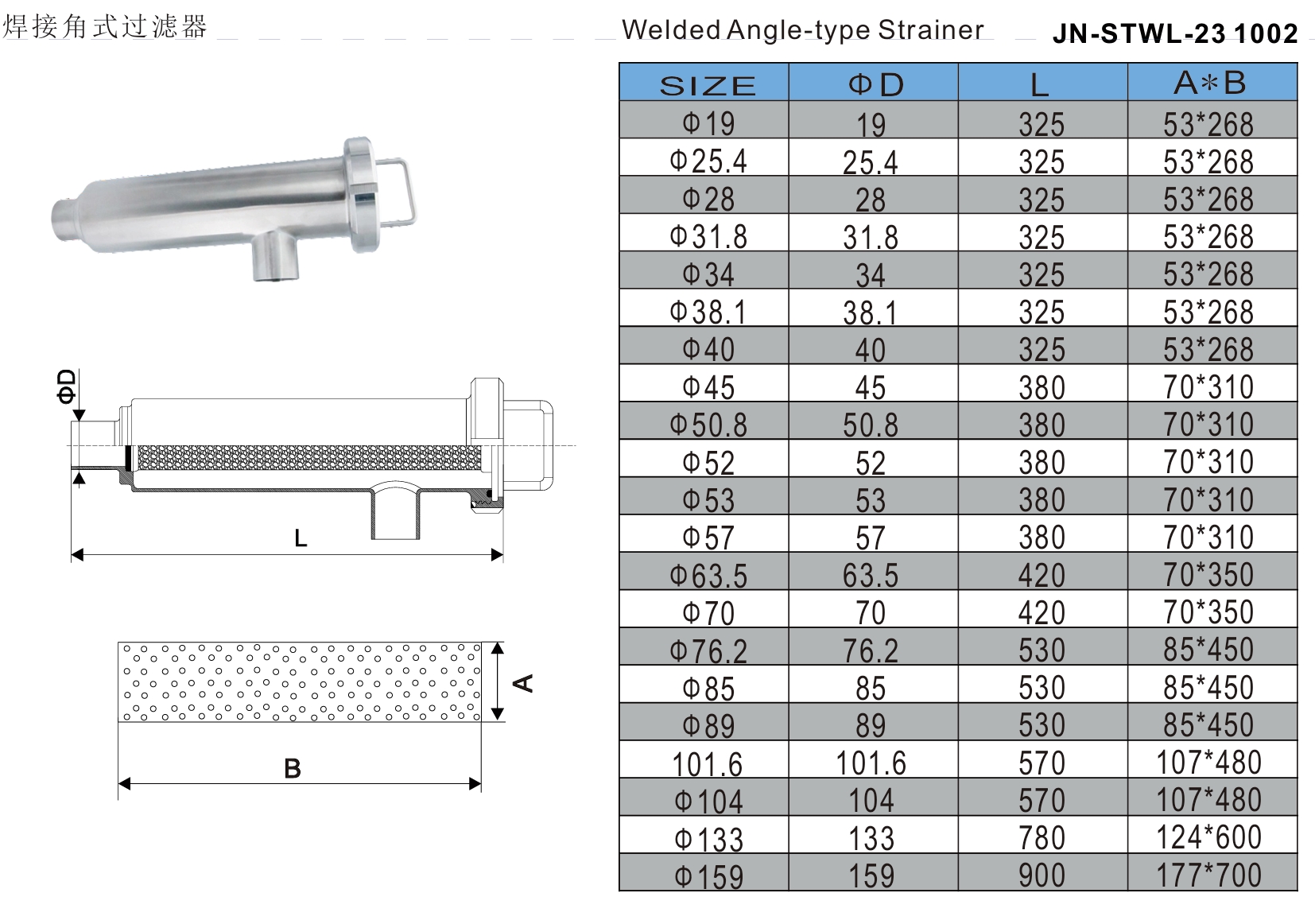

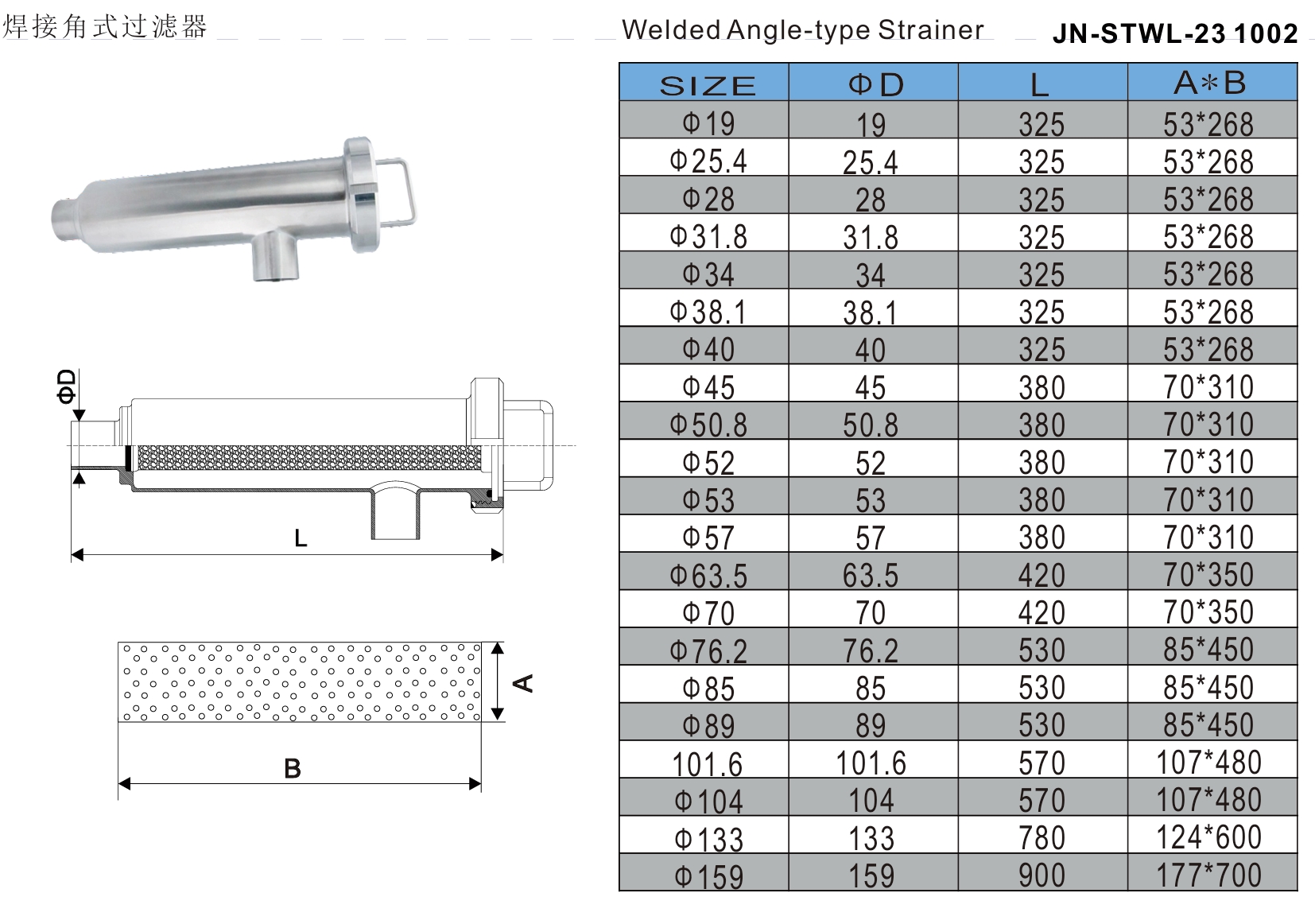

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● The stainless steel sanitary angle filter adopts a carefully designed filter mesh structure, and its filter element area is far greater than that of conventional filters.

● The stainless steel sanitary angle filter adopts a carefully designed filter mesh structure, and its filter element area is far greater than that of conventional filters.

● The built-in flushing mechanism of the stainless steel sanitary angle filter can effectively remove impurities accumulated on the surface of the filter element.

● The stainless steel sanitary angle filter is equipped with a real-time pressure monitoring system, which can accurately monitor the pressure changes on both sides of the filter element. Once an abnormal pressure fluctuation is detected, the system will automatically alarm and take corresponding measures.

● The stainless steel sanitary angle filter is designed with multiple filter layers inside, each with a different pore size, which is used to grade and filter impurities of different sizes.

● The stainless steel sanitary angle filter is designed with an adjustable flow rate distribution device. Through reasonable flow rate distribution, the contact time of the fluid in the filter is increased, and the filtering effect is enhanced.

Application

Stainless steel sanitary angle filters are widely used in the following industries: Food processing industry: used to remove impurities and particles from food liquids. Beverage production industry: ensure that the raw materials in beverages remain pure and free of impurities. Pharmaceutical industry: filter contaminants that may exist in the production process of drugs. Dairy industry: filter impurities in milk to ensure product quality. Cosmetics production: filter cosmetic raw materials to ensure that the product is pollution-free. Water treatment industry: used for water quality filtration to remove bacteria and impurities in water.

Working Principles

The working principle of the stainless steel sanitary angle filter is based on the principle of physical filtration, and the solid impurities in the fluid are intercepted by the filter or screen inside it. The fluid first enters the filter, passes through the inlet pipe of the filter, and enters the filter cavity. When the fluid flows through the filter, larger particulate matter is intercepted by the filter, and the purified fluid flows out smoothly through the outlet. The pore size of the filter can be selected according to needs to meet the requirements of different filtration accuracy. When impurities accumulate to a certain extent, clean or replace the filter to ensure the filtration effect. This process does not require external force and is completely driven by the pressure of the fluid.

The options for stainless steel sanitary angle filters include:

Filter material: stainless steel, ceramic, nylon and other materials can be selected.

Filter accuracy: Filters with different pore sizes (such as 20μm, 50μm, 100μm, etc.) can be selected according to needs.

Cleaning method: manual cleaning or automatic cleaning.

Connection method: quick-install, flange, threaded, etc.

Flow size: filter adapted to different flow requirements.

Dimensions: select the appropriate size and design according to the pipeline space.

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● The stainless steel sanitary angle filter adopts a carefully designed filter mesh structure, and its filter element area is far greater than that of conventional filters.

● The stainless steel sanitary angle filter adopts a carefully designed filter mesh structure, and its filter element area is far greater than that of conventional filters.

● The built-in flushing mechanism of the stainless steel sanitary angle filter can effectively remove impurities accumulated on the surface of the filter element.

● The stainless steel sanitary angle filter is equipped with a real-time pressure monitoring system, which can accurately monitor the pressure changes on both sides of the filter element. Once an abnormal pressure fluctuation is detected, the system will automatically alarm and take corresponding measures.

● The stainless steel sanitary angle filter is designed with multiple filter layers inside, each with a different pore size, which is used to grade and filter impurities of different sizes.

● The stainless steel sanitary angle filter is designed with an adjustable flow rate distribution device. Through reasonable flow rate distribution, the contact time of the fluid in the filter is increased, and the filtering effect is enhanced.

Application

Stainless steel sanitary angle filters are widely used in the following industries: Food processing industry: used to remove impurities and particles from food liquids. Beverage production industry: ensure that the raw materials in beverages remain pure and free of impurities. Pharmaceutical industry: filter contaminants that may exist in the production process of drugs. Dairy industry: filter impurities in milk to ensure product quality. Cosmetics production: filter cosmetic raw materials to ensure that the product is pollution-free. Water treatment industry: used for water quality filtration to remove bacteria and impurities in water.