| Availability: | |

|---|---|

| Quantity: | |

DIN JN-BV 1001

JONENG

8481804090

Stainless Steel Sanitary Welded Duckbill Manual Butterfly Valve

The stainless steel sanitary welded duckbill manual butterfly valve is designed to meet the fluid control requirements of high sanitation requirements while providing efficient flow regulation functions. Its unique duckbill shape helps the fluid to pass smoothly, reducing the retention of fluid in the valve, thereby reducing the risk of contamination. Through manual operation, the valve can accurately adjust the flow and avoid common fault problems in automation systems. In addition, the valve has a simple structure and is suitable for the installation of sanitary pipeline systems. It can ensure that the fluid is not contaminated during the flow process and meets strict hygiene standards.

Working Principles

The working principle of the stainless steel sanitary welded duckbill manual butterfly valve relies on the rotation of the butterfly plate in the valve body to control the flow of the fluid. When the valve stem is rotated manually, the connected butterfly plate rotates 90 degrees inside the valve body. The unique duckbill shape of the butterfly plate makes the change of valve opening smoother, which can effectively adjust the flow of fluid or completely close the flow channel. When closed, the design of the duckbill butterfly plate can achieve a tighter seal, prevent fluid residue, and reduce the risk of contamination.

The options of stainless steel sanitary welded duckbill manual butterfly valve include:

Material selection: 304 or 316L stainless steel.

Sealing material: fluororubber, silicone, PTFE, etc.

Manual operation mode: lever, handwheel, gear drive.

Connection mode: welding, flange connection.

Seal type: double seal or single seal design.

Valve body surface treatment: polishing, sandblasting, pickling.

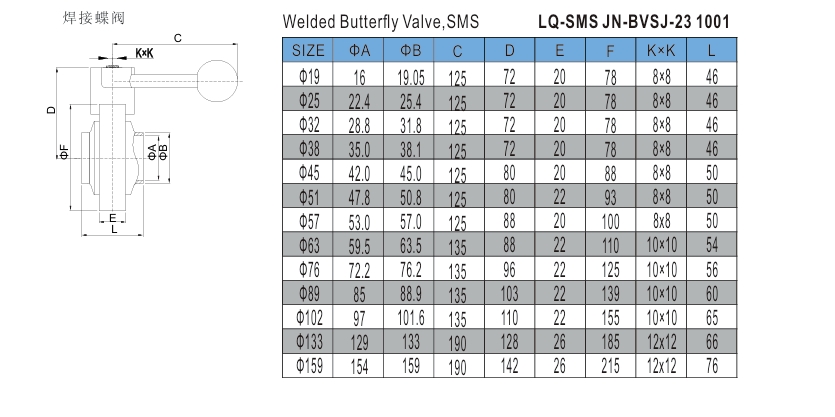

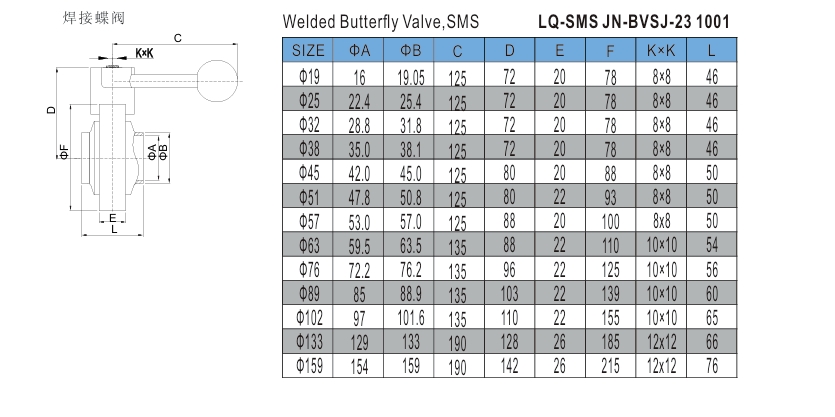

Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Valve parts

Body | Stainless steel AISI316L or AISI 304 (1.4301/1.4404) |

Disc | AISI304 or AISI316L |

Pull-position handle | Stainless Steel Material, Round type or square type |

Multi-position Gripper Handle | ABS gripper handle, SS gripper handle, 2/3/4/12 positions to adjustment, Universal type |

Gasket | EPDM, VITON(FPM), Silicone, different color is available |

Bushing | EPDM or PTFE, other material request |

Nut | Stainless Steel 304 or 316 Material or other request |

Bolt | Stainless Steel 304 or 316 Material or other request |

Features

● The butterfly plate of the stainless steel sanitary welded duckbill manual butterfly valve adopts a duckbill design, which can ensure the smoothness of the fluid when it flows through the valve and reduce eddy currents and turbulence.

● The stainless steel sanitary welded duckbill manual butterfly valve adopts a double sealing system, and the seal between the valve body and the butterfly plate is tighter than that of ordinary valves.

● The surface of the stainless steel sanitary welded duckbill manual butterfly valve plate is polished inside and outside, which not only improves the aesthetics, but also reduces the retention of materials in the valve to ensure cleanliness and hygiene.

● The stainless steel sanitary welded duckbill manual butterfly valve is designed with an automatic exhaust function, which can automatically exhaust the air or gas in the pipeline during the closing process to avoid operational difficulties caused by gas accumulation.

● The stainless steel sanitary welded duckbill manual butterfly valve is designed to withstand higher temperatures, especially in the transportation of steam, hot water or other high-temperature fluids, and can work stably without being affected by thermal deformation.

● The stainless steel sanitary welded duckbill manual butterfly valve adopts a special fluid dynamics design, so that even at a large flow rate, it can still maintain accurate flow regulation and adapt to various working conditions.

Application

Stainless steel sanitary welded duckbill manual butterfly valve is widely used in the following industries: Food industry: used to adjust the flow control of liquids such as syrup, dairy products, and juice. Pharmaceutical industry: control the flow of drug solutions during pharmaceutical production. Cosmetics industry: used to precisely control the delivery of lotions, skin care products and other fluids. Beverage industry: used to control the flow of beverages, juices and other liquids. Chemical industry: to control the flow in fluid pipelines such as chemicals and solvents. Dairy industry: used to control the flow and distribution of fluids in the production process of dairy products.

Working Principles

The working principle of the stainless steel sanitary welded duckbill manual butterfly valve relies on the rotation of the butterfly plate in the valve body to control the flow of the fluid. When the valve stem is rotated manually, the connected butterfly plate rotates 90 degrees inside the valve body. The unique duckbill shape of the butterfly plate makes the change of valve opening smoother, which can effectively adjust the flow of fluid or completely close the flow channel. When closed, the design of the duckbill butterfly plate can achieve a tighter seal, prevent fluid residue, and reduce the risk of contamination.

The options of stainless steel sanitary welded duckbill manual butterfly valve include:

Material selection: 304 or 316L stainless steel.

Sealing material: fluororubber, silicone, PTFE, etc.

Manual operation mode: lever, handwheel, gear drive.

Connection mode: welding, flange connection.

Seal type: double seal or single seal design.

Valve body surface treatment: polishing, sandblasting, pickling.

Specification Chart

Working Pressure | 10 Bar (Max. Pressure is 16bar for but welded connection in small sizes |

Working temperature | -10ºC TO + 120ºC |

Size | 1/2”-12”, DN15-DN300 |

Grade | AISI304 and AISI316L |

FDA approved gaskets in silicone, EPDM, viton, PTFE | |

Connection | Clamp, Weld, Thread,male threaded; female threaded; flange end;union connection |

Surface | Sanitary inside polish (Ra ≤ 0.8 μm) |

Sanitary outside polish (Ra ≤1.6 μm) | |

Standard | ISO, 3A, SMS, RJT, DIN and so on |

Butterfly valve disc and body is made from forging | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

Features

● The butterfly plate of the stainless steel sanitary welded duckbill manual butterfly valve adopts a duckbill design, which can ensure the smoothness of the fluid when it flows through the valve and reduce eddy currents and turbulence.

● The stainless steel sanitary welded duckbill manual butterfly valve adopts a double sealing system, and the seal between the valve body and the butterfly plate is tighter than that of ordinary valves.

● The surface of the stainless steel sanitary welded duckbill manual butterfly valve plate is polished inside and outside, which not only improves the aesthetics, but also reduces the retention of materials in the valve to ensure cleanliness and hygiene.

● The stainless steel sanitary welded duckbill manual butterfly valve is designed with an automatic exhaust function, which can automatically exhaust the air or gas in the pipeline during the closing process to avoid operational difficulties caused by gas accumulation.

● The stainless steel sanitary welded duckbill manual butterfly valve is designed to withstand higher temperatures, especially in the transportation of steam, hot water or other high-temperature fluids, and can work stably without being affected by thermal deformation.

● The stainless steel sanitary welded duckbill manual butterfly valve adopts a special fluid dynamics design, so that even at a large flow rate, it can still maintain accurate flow regulation and adapt to various working conditions.

Application

Stainless steel sanitary welded duckbill manual butterfly valve is widely used in the following industries: Food industry: used to adjust the flow control of liquids such as syrup, dairy products, and juice. Pharmaceutical industry: control the flow of drug solutions during pharmaceutical production. Cosmetics industry: used to precisely control the delivery of lotions, skin care products and other fluids. Beverage industry: used to control the flow of beverages, juices and other liquids. Chemical industry: to control the flow in fluid pipelines such as chemicals and solvents. Dairy industry: used to control the flow and distribution of fluids in the production process of dairy products.