| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary T-type filter is a high-cleanliness precision filtration equipment that uses a T-shaped structure to optimize the fluid path and reduce turbulence and resistance. Its core component is a high-precision filter element, which can efficiently intercept particulate impurities. It also has the characteristics of easy cleaning and low retention, and is widely used in aseptic fluid control systems. The stainless steel sanitary T-type filter is mainly installed at the inlet of the fluid pipeline, before the pump, before the valve or at the key process node to remove particulate impurities, protect precision equipment, and prevent blockage or contamination. The stainless steel sanitary T-type filter mainly has the following types: standard T-type filter, high-precision filter element T-type filter, quick-install T-type filter, high-pressure T-type filter, and large-flow T-type filter.

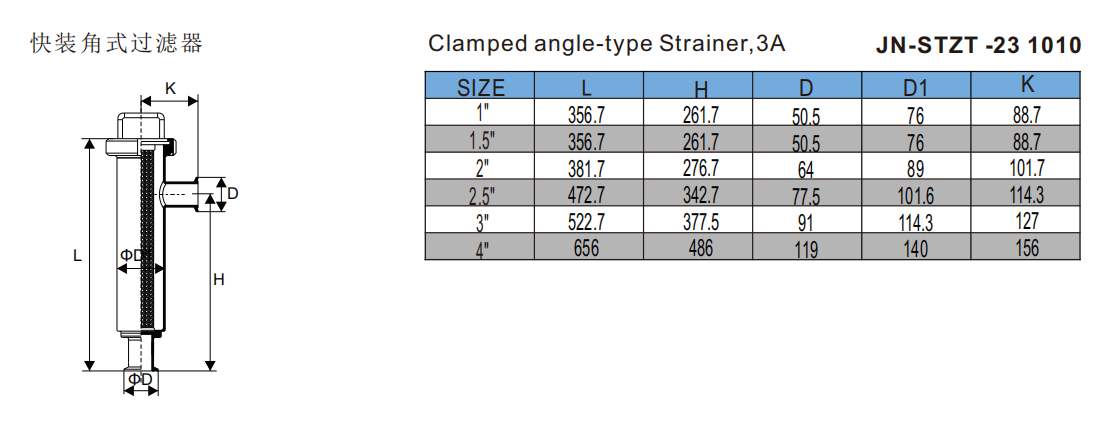

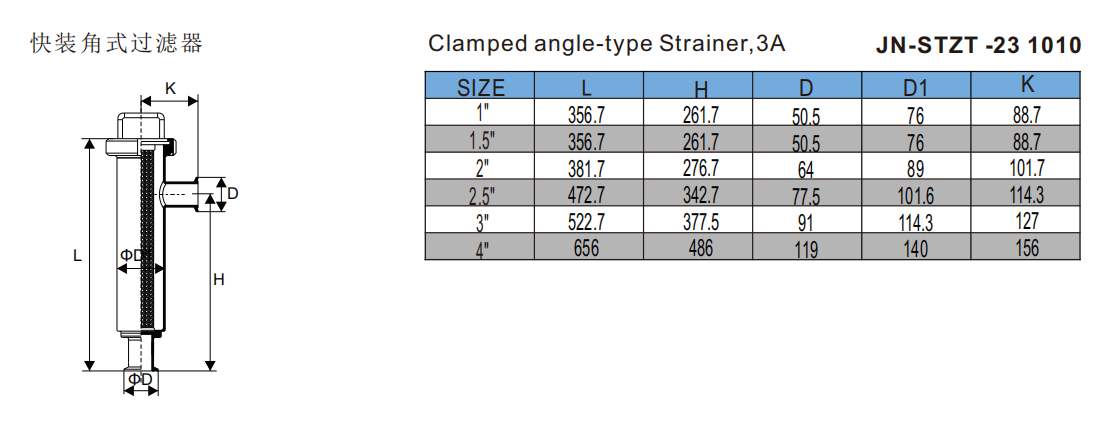

JN-STZT-23 1010

JONENG

8421219990

Stainless Steel Sanitary Welded T-type Water Filter Housing Cartridge

The stainless steel sanitary T-type filter is designed to achieve high-cleanliness fluid filtration and ensure that the production process is pollution-free and free of particulate interference. Its design goal is to remove tiny impurities, prevent equipment blockage or contamination, and ensure the high purity of the fluid and stable operation of the system. At the same time, by optimizing the fluid channel, the resistance is reduced, the energy consumption is reduced, and the filtration efficiency is improved. The use of sanitary stainless steel materials and polishing technology meets GMP, FDA and other standards, ensures the strict hygiene requirements of food, pharmaceutical, biotechnology and other industries, and achieves sterile, safe and efficient fluid management.

Working Principles

The working principle of the stainless steel sanitary T-type filter is to intercept impurities in the fluid through an internal high-precision filter or filter element, thereby ensuring the cleanliness of the downstream fluid. When the fluid enters the filter housing from the inlet and outlet, solid particles or suspended matter are intercepted on the surface of the filter when passing through the filter, and the clean liquid flows to the outlet through the filter element. The use of stainless steel sanitary T-type filters can effectively filter micron and nanometer particles, prevent extremely small pollutants from affecting product purity, and improve the quality of terminal products.

The options of stainless steel sanitary T-type filters include:

Filter element type: micron stainless steel mesh, PE, PTFE, etc. are optional

Connection method: quick installation, welding, flange, thread, etc.

Seal material: EPDM, PTFE, FKM, etc. meet FDA standards

Drainage method: manual drainage, automatic drainage, backwashing function

Surface treatment: mirror polishing, electrolytic polishing, sandblasting

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | Silicone, EPDM, Viton, PTFE |

End connection | sanitary clamp, butt weld,threaded, union... |

Standard | 3A, DIN, SMS, ISO |

Mesh size | from 0.5mm to 2.0mm |

Screen | from 20 mesh to 300 mesh |

Internal/External Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

Features

● The T-shaped structure of the stainless steel sanitary T-type filter allows the fluid to pass through multiple filtration channels, effectively improving the filtration efficiency and reducing fluid resistance.

● The filter element design of the stainless steel sanitary T-type filter can adjust the pore size according to the process requirements to adapt to the filtration requirements of different particulate matter.

● The stainless steel sanitary T-type filter adopts backwashing or automatic slag discharge design to reduce manual intervention and maintain the long-term stability of the filter.

● The stainless steel sanitary T-type filter uses filter screens with different pore sizes from 0.5μm to 200μm to ensure that the filtration accuracy meets strict requirements.

● The stainless steel sanitary T-type filter optimizes the flow channel design to reduce the pressure loss when the fluid passes through and maintain the system efficiency.

● The stainless steel sanitary T-type filter can choose welding, quick installation, flange and other connection methods according to the needs to adapt to different pipeline systems.

Application

Stainless steel sanitary T-type filters are widely used in the following industries, pharmaceutical industry: filter liquid medicine to ensure sterility and product purity. Food industry: prevent impurities from entering the food production process. Biotechnology: filter biological products to maintain high purity. Cosmetic industry: filter cosmetic ingredients to prevent contamination. Dairy industry: filter dairy products to ensure sterility and quality. Beverage industry: ensure fluid cleanliness during beverage production. Water treatment industry: remove impurities in water to ensure water quality.

Working Principles

The working principle of the stainless steel sanitary T-type filter is to intercept impurities in the fluid through an internal high-precision filter or filter element, thereby ensuring the cleanliness of the downstream fluid. When the fluid enters the filter housing from the inlet and outlet, solid particles or suspended matter are intercepted on the surface of the filter when passing through the filter, and the clean liquid flows to the outlet through the filter element. The use of stainless steel sanitary T-type filters can effectively filter micron and nanometer particles, prevent extremely small pollutants from affecting product purity, and improve the quality of terminal products.

The options of stainless steel sanitary T-type filters include:

Filter element type: micron stainless steel mesh, PE, PTFE, etc. are optional

Connection method: quick installation, welding, flange, thread, etc.

Seal material: EPDM, PTFE, FKM, etc. meet FDA standards

Drainage method: manual drainage, automatic drainage, backwashing function

Surface treatment: mirror polishing, electrolytic polishing, sandblasting

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● The T-shaped structure of the stainless steel sanitary T-type filter allows the fluid to pass through multiple filtration channels, effectively improving the filtration efficiency and reducing fluid resistance.

● The filter element design of the stainless steel sanitary T-type filter can adjust the pore size according to the process requirements to adapt to the filtration requirements of different particulate matter.

● The stainless steel sanitary T-type filter adopts backwashing or automatic slag discharge design to reduce manual intervention and maintain the long-term stability of the filter.

● The stainless steel sanitary T-type filter uses filter screens with different pore sizes from 0.5μm to 200μm to ensure that the filtration accuracy meets strict requirements.

● The stainless steel sanitary T-type filter optimizes the flow channel design to reduce the pressure loss when the fluid passes through and maintain the system efficiency.

● The stainless steel sanitary T-type filter can choose welding, quick installation, flange and other connection methods according to the needs to adapt to different pipeline systems.

Application

Stainless steel sanitary T-type filters are widely used in the following industries, pharmaceutical industry: filter liquid medicine to ensure sterility and product purity. Food industry: prevent impurities from entering the food production process. Biotechnology: filter biological products to maintain high purity. Cosmetic industry: filter cosmetic ingredients to prevent contamination. Dairy industry: filter dairy products to ensure sterility and quality. Beverage industry: ensure fluid cleanliness during beverage production. Water treatment industry: remove impurities in water to ensure water quality.