| Availability: | |

|---|---|

| Quantity: | |

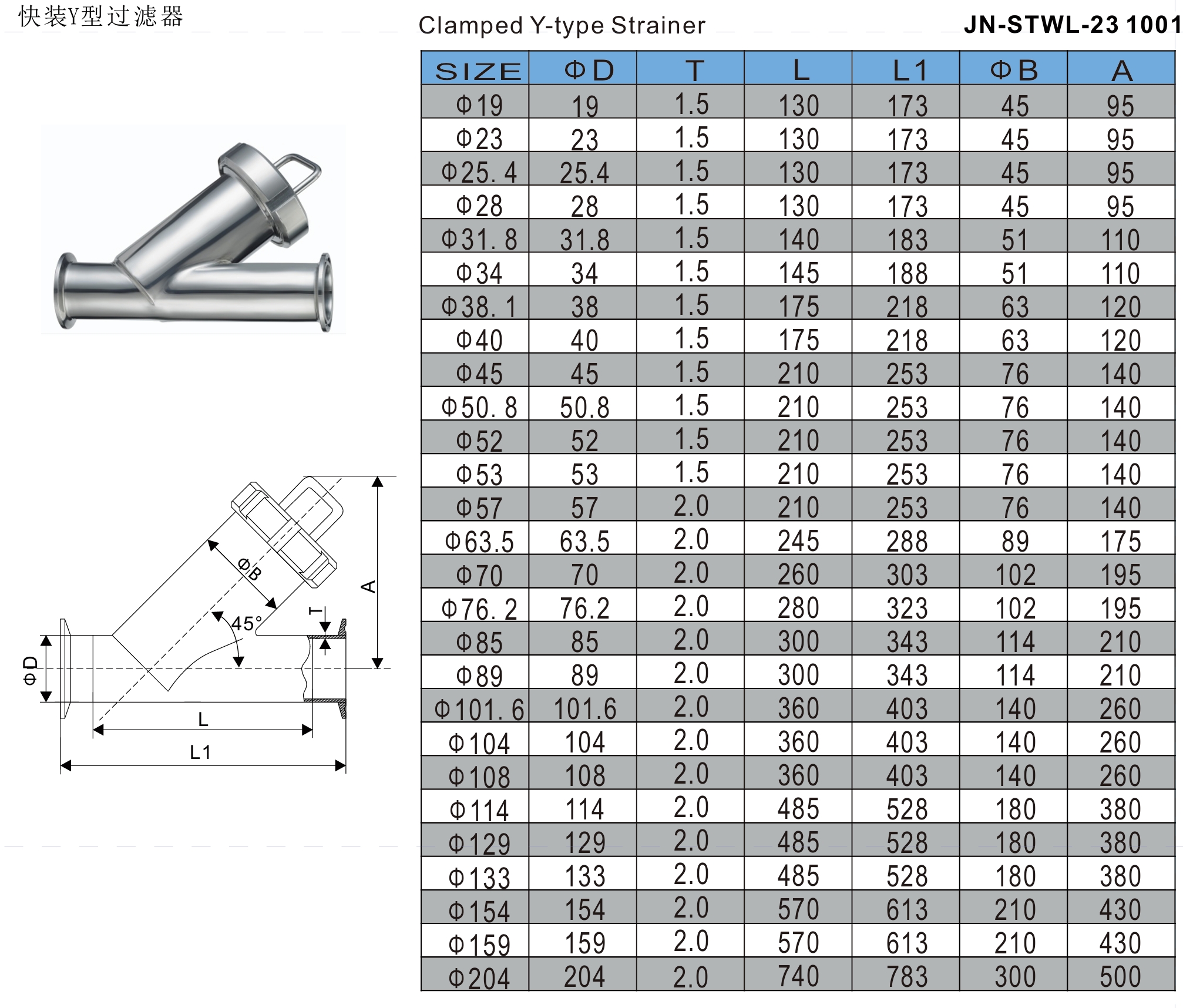

The stainless steel sanitary Y-type welded filter is a filtering device used in the pipeline system. It is usually installed at the entrance of the pipeline system, especially in the initial stage of liquid flow. It is installed in front of the pump, the main pipeline or at the location connected to other key equipment to ensure that the fluid entering the system is thoroughly filtered before entering the important equipment. According to the design, function and application requirements, there are several common types of stainless steel sanitary Y-type welded filters: single-tube filter, double-tube filter, filter with automatic cleaning function, clamp-type connection filter, high-pressure filter, low-flow filter.

JN-STZT-23 1010

JONENG

8421219990

Stainless Steel Sanitary Welded Y-type Single Cartridge Filter for Food

The stainless steel sanitary Y-type welded filter is designed to solve the potential threat of impurities to equipment in the pipeline system, especially when there are often tiny particles or solid substances in the fluid. Through its Y-type design, the filter can effectively intercept these impurities and prevent them from entering downstream equipment such as pumps, valves or sensors, avoiding equipment damage or performance degradation. The welded structure ensures high sealing and high-pressure resistance. At the same time, its sanitary material meets the strict hygiene requirements of the food, pharmaceutical and other industries to ensure the purity and safety of the product. In this way, the filter not only ensures the stable operation of the system, but also reduces the workload of maintenance and cleaning.

Working Principles

The stainless steel sanitary Y-type welded filter achieves precise filtration through its unique Y-type design. When working, the fluid first enters the Y-type structure through the inlet of the filter. As the fluid flows and enters the fluid channel, the filter element or mesh layer in the filter will intercept impurities or solid particles in the fluid. These particles are large in size and cannot pass through the fine mesh or filter element pores, and are eventually blocked in the filter. At the same time, the flow rate and pressure of the fluid change during the passage, which will accelerate the filtration of sediments. As impurities accumulate, the filter will gradually increase the resistance to fluid flow. At this time, the filter element needs to be cleaned or replaced regularly to maintain the flow and filtration effect of the system.

The options of the stainless steel sanitary Y-type welded filter include:

Filter material: stainless steel 304/316L, polyester, nylon.

Filter element type: optional pore size to meet different filtration needs.

Connection method: clamp connection, welding, threaded connection.

Cleaning method: manual cleaning, automatic cleaning.

Filter shape: single-tube or double-tube design.

Pressure level: high-pressure or low-pressure models can be selected according to needs.

External coating: anti-corrosion coating, mirror polishing, etc.

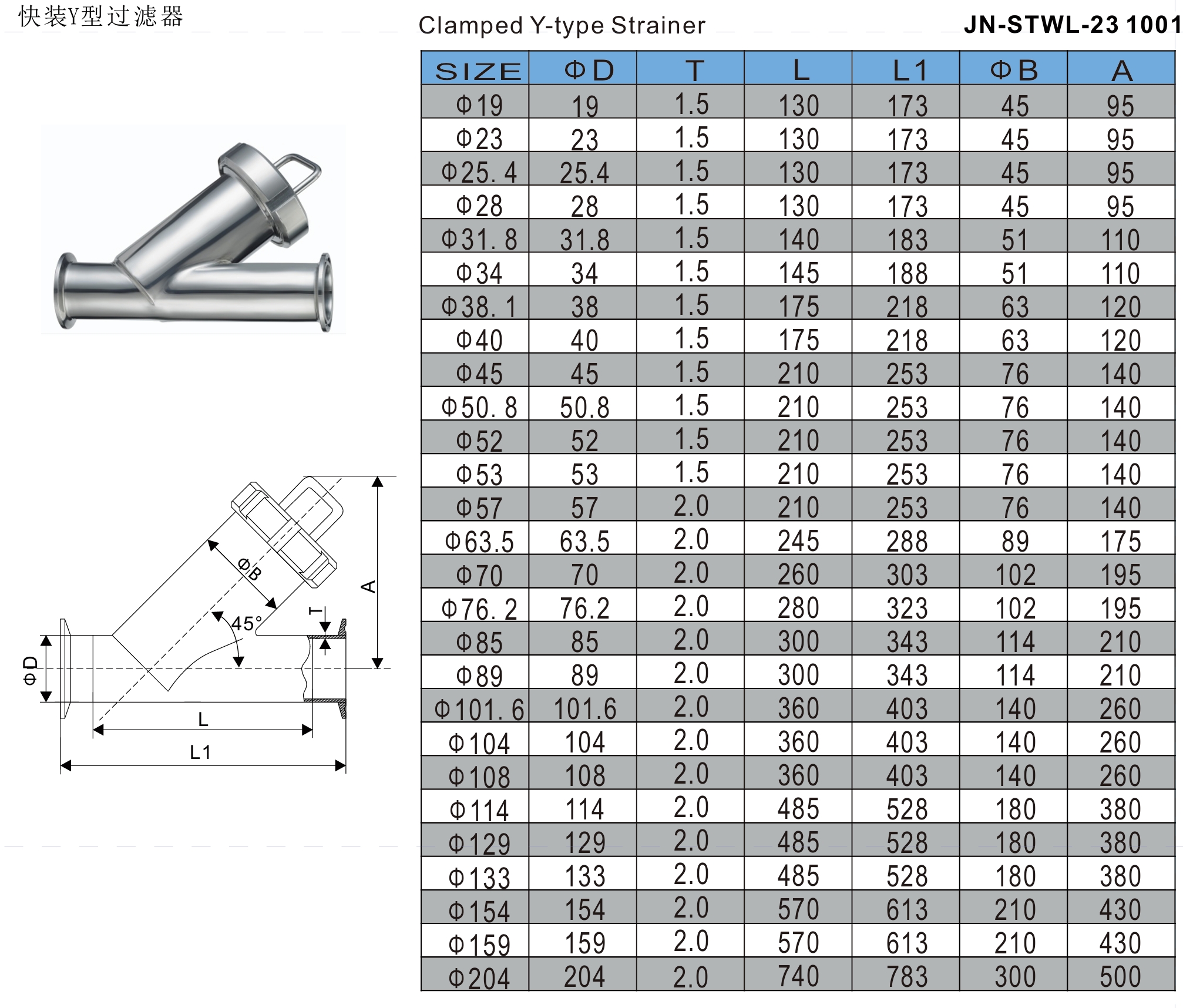

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | Silicone, EPDM, Viton, PTFE |

End connection | sanitary clamp, butt weld,threaded, union... |

Standard | 3A, DIN, SMS, ISO |

Mesh size | from 0.5mm to 2.0mm |

Screen | from 20 mesh to 300 mesh |

Internal/External Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

Features

● The internal structure of the stainless steel sanitary Y-type welded filter is carefully designed to ensure that there are no dead corners, avoiding the accumulation of liquid or impurities inside the filter and the breeding of microorganisms.

● The stainless steel sanitary Y-type welded filter adopts a high-precision porous grid structure, which can be customized according to the size of different particles to ensure that every drop of fluid in the system is accurately filtered.

● The stainless steel sanitary Y-type welded filter adopts a high-temperature resistant and corrosion-resistant coating, which can withstand high temperature fluctuations and corrosion from chemicals, extending the service life of the equipment.

● The stainless steel sanitary Y-type welded filter adopts a quick disassembly design, which can quickly replace or clean the filter element without completely disassembling the entire equipment.

● The filter element surface of the stainless steel sanitary Y-type welded filter is specially treated with anti-scaling function, which can effectively resist the deposition of minerals or impurities in the fluid.

● The stainless steel sanitary Y-type welded filter adopts a multi-stage filtration structure, which usually includes two or more filtration levels of coarse filtration and fine filtration.

Application

Stainless steel sanitary Y-type welded filters are widely used in the following industries: Food industry: used for liquid food filtration to ensure no impurities and pollution. Beverage industry: filter beverage raw materials and finished products to maintain stable product quality. Pharmaceutical industry: filter raw materials and pharmaceutical liquids to prevent impurities from affecting quality. Chemical industry: remove impurities from chemicals to ensure production safety. Dairy industry: filter dairy liquid to keep it sanitary. Water treatment industry: purify water sources and remove solid particles in water. Cosmetics industry: filter raw material liquid to ensure product purity.

Working Principles

The stainless steel sanitary Y-type welded filter achieves precise filtration through its unique Y-type design. When working, the fluid first enters the Y-type structure through the inlet of the filter. As the fluid flows and enters the fluid channel, the filter element or mesh layer in the filter will intercept impurities or solid particles in the fluid. These particles are large in size and cannot pass through the fine mesh or filter element pores, and are eventually blocked in the filter. At the same time, the flow rate and pressure of the fluid change during the passage, which will accelerate the filtration of sediments. As impurities accumulate, the filter will gradually increase the resistance to fluid flow. At this time, the filter element needs to be cleaned or replaced regularly to maintain the flow and filtration effect of the system.

The options of the stainless steel sanitary Y-type welded filter include:

Filter material: stainless steel 304/316L, polyester, nylon.

Filter element type: optional pore size to meet different filtration needs.

Connection method: clamp connection, welding, threaded connection.

Cleaning method: manual cleaning, automatic cleaning.

Filter shape: single-tube or double-tube design.

Pressure level: high-pressure or low-pressure models can be selected according to needs.

External coating: anti-corrosion coating, mirror polishing, etc.

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● The internal structure of the stainless steel sanitary Y-type welded filter is carefully designed to ensure that there are no dead corners, avoiding the accumulation of liquid or impurities inside the filter and the breeding of microorganisms.

● The stainless steel sanitary Y-type welded filter adopts a high-precision porous grid structure, which can be customized according to the size of different particles to ensure that every drop of fluid in the system is accurately filtered.

● The stainless steel sanitary Y-type welded filter adopts a high-temperature resistant and corrosion-resistant coating, which can withstand high temperature fluctuations and corrosion from chemicals, extending the service life of the equipment.

● The stainless steel sanitary Y-type welded filter adopts a quick disassembly design, which can quickly replace or clean the filter element without completely disassembling the entire equipment.

● The filter element surface of the stainless steel sanitary Y-type welded filter is specially treated with anti-scaling function, which can effectively resist the deposition of minerals or impurities in the fluid.

● The stainless steel sanitary Y-type welded filter adopts a multi-stage filtration structure, which usually includes two or more filtration levels of coarse filtration and fine filtration.

Application

Stainless steel sanitary Y-type welded filters are widely used in the following industries: Food industry: used for liquid food filtration to ensure no impurities and pollution. Beverage industry: filter beverage raw materials and finished products to maintain stable product quality. Pharmaceutical industry: filter raw materials and pharmaceutical liquids to prevent impurities from affecting quality. Chemical industry: remove impurities from chemicals to ensure production safety. Dairy industry: filter dairy liquid to keep it sanitary. Water treatment industry: purify water sources and remove solid particles in water. Cosmetics industry: filter raw material liquid to ensure product purity.