| Availability: | |

|---|---|

| Quantity: | |

Stainless steel sanitary angle reducer filter is a kind of equipment designed for industries with high hygiene requirements, usually used for filtering liquids or gases. Stainless steel sanitary angle reducer filter is usually used in sanitary piping systems in food, beverage, pharmaceutical and other industries. The installation location is mainly concentrated in the pipeline section where fluid filtration is required, and it is generally installed in the key position of the feed pipeline or delivery pipeline. The common types of stainless steel sanitary angle reducer filters are mainly distinguished according to different filtering methods and pipeline connection methods. Common types include: Y-type filter, T-type filter, porous filter, quick-open filter.

JN-STZT-23 1007

JONENG

8421219990

Stainless Steel Sanitary Welding Angle Reducer Filter for Drinks

The purpose of the design of stainless steel sanitary angle reducer filter is to optimize the space and fluid flow efficiency to the greatest extent while ensuring the cleanliness of the fluid. Its angle structure can not only solve the installation problem in a small space, but also avoid the problem of slow fluid flow rate or excessive local resistance that may be caused by traditional filters. Through the cleverly designed reducer transition, the filter can smoothly guide the fluid, remove impurities through precision filtration, avoid the contamination of equipment or finished products by tiny particles in the system, and ensure the stability of the production process and the safety of the final product, especially in the strict food, beverage and pharmaceutical industries.

Working Principles

The working principle of the stainless steel sanitary angle reducer filter is based on the process of fluid passing through the filter medium. First, the fluid enters the inlet end of the filter, and the fluid enters the filter through the angle pipe design. The filter is equipped with a precision filter screen or filter element. When the fluid flows through the filter screen, larger particles, impurities or contaminants are intercepted on the surface or inside of the filter screen, and the purified fluid flows out through the outlet. The use of stainless steel sanitary angle reducer filters can avoid uneven flow rate or pressure fluctuations, ensuring that the fluid enters the key equipment at a stable flow rate.

The options of stainless steel sanitary angle reducer filters include:

Filtration accuracy: filter screens or filter elements with different pore sizes to meet different particle filtration requirements.

Connection method: threaded connection, clamping or welding, suitable for different pipeline interfaces.

Material: different grades of stainless steel materials can be selected, such as 304, 316L, etc.

Cleaning method: manual cleaning or automatic backwashing function.

Filter type: Y-type, T-type or porous, etc., selected according to pipeline layout and needs.

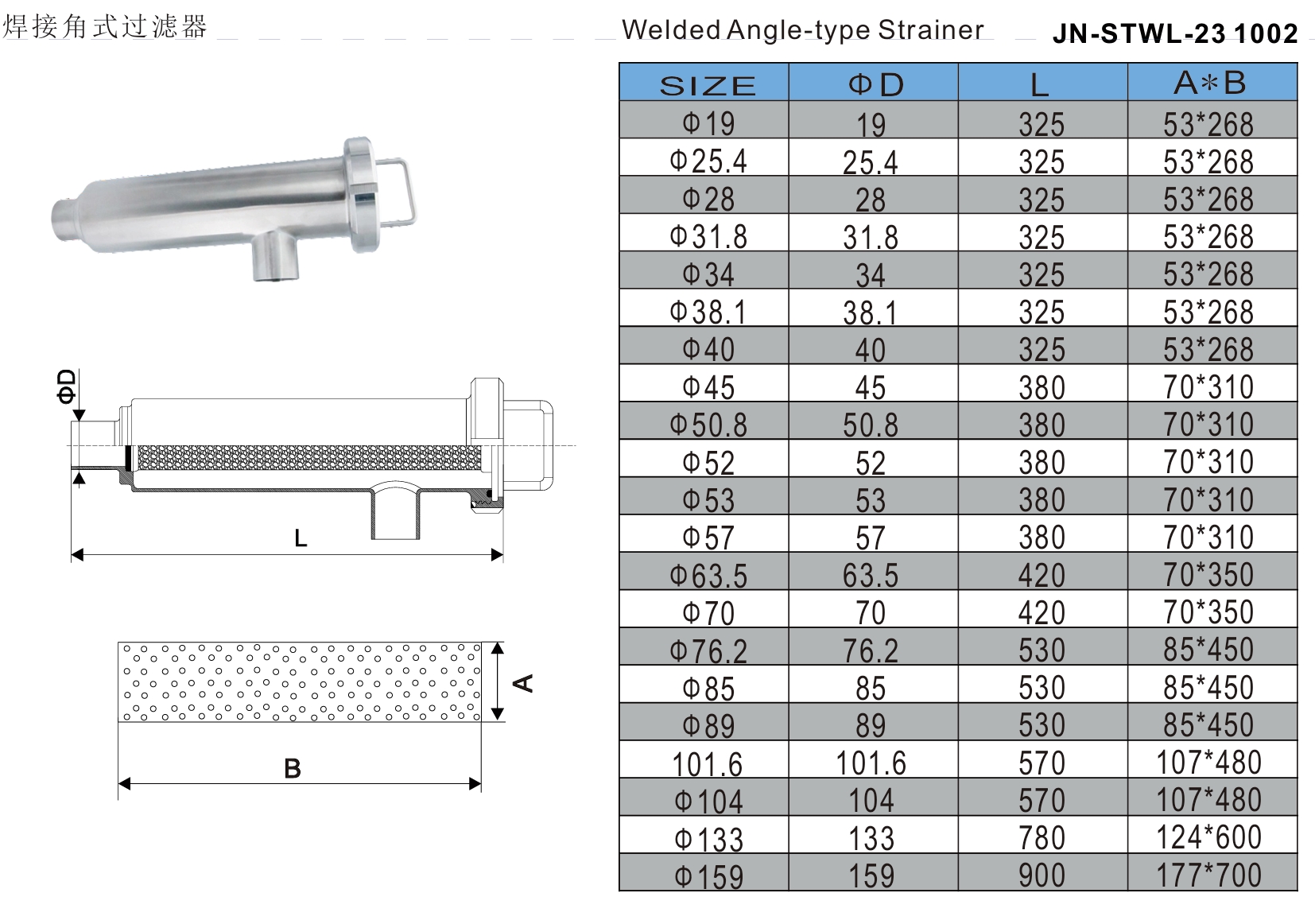

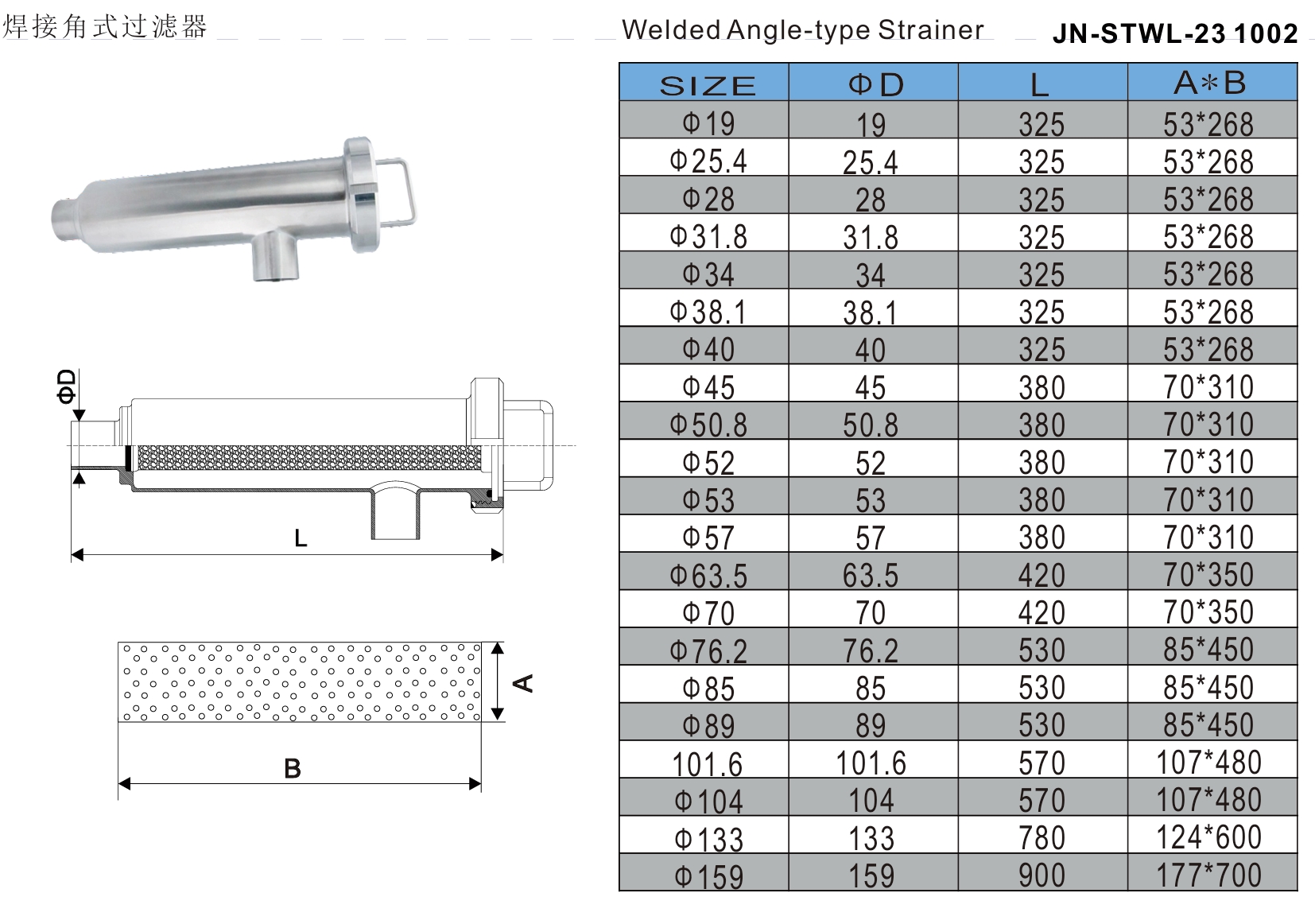

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | Silicone, EPDM, Viton, PTFE |

End connection | sanitary clamp, butt weld,threaded, union... |

Standard | 3A, DIN, SMS, ISO |

Mesh size | from 0.5mm to 2.0mm |

Screen | from 20 mesh to 300 mesh |

Internal/External Finish | Ra 16 ~ 32µin (0.4 ~ 0.8µm) |

Features

● The stainless steel sanitary angle reducer filter adopts a unique fluid distribution design, which optimizes the inlet distribution of the fluid through the angle structure.

● The internal flow channel of the stainless steel sanitary angle reducer filter has been finely designed, and a streamlined surface is adopted to reduce the turbulence and resistance of the fluid.

● The stainless steel sanitary angle reducer filter is designed with an adjustable filter element clamping system, which can adjust the tightness of the filter element according to the actual filtering needs to improve the filtering effect.

● The stainless steel sanitary angle reducer filter is equipped with a quick disassembly design, and the filter element and other internal components can be easily disassembled, which is convenient for quick cleaning and maintenance, reducing equipment downtime.

● The stainless steel sanitary angle reducer filter adopts a double sealing design. The inlet and outlet and cover of the filter are equipped with two layers of sealing rings, which further enhances the sealing performance and prevents leakage.

● The stainless steel sanitary angle reducer filter is equipped with an automatic backwashing function, which regularly backwashes the filter element through an intelligent control system to remove accumulated impurities.

Application

Stainless steel sanitary angle reducer filters are widely used in the following industries, food industry: ensure liquid filtration and prevent impurities from affecting food safety. Beverage industry: filter raw water and finished beverages to ensure product quality. Pharmaceutical industry: clean filtration to prevent impurities from contaminating drugs and production equipment. Chemical industry: filter chemicals to prevent particulate matter from affecting the reaction process. Dairy industry: ensure the cleanliness of dairy products to prevent impurities from affecting taste and quality. Water treatment industry: remove impurities in water to ensure clean water quality and stable system. Biotechnology industry: filter cell culture fluid to keep the culture environment pollution-free.

Working Principles

The working principle of the stainless steel sanitary angle reducer filter is based on the process of fluid passing through the filter medium. First, the fluid enters the inlet end of the filter, and the fluid enters the filter through the angle pipe design. The filter is equipped with a precision filter screen or filter element. When the fluid flows through the filter screen, larger particles, impurities or contaminants are intercepted on the surface or inside of the filter screen, and the purified fluid flows out through the outlet. The use of stainless steel sanitary angle reducer filters can avoid uneven flow rate or pressure fluctuations, ensuring that the fluid enters the key equipment at a stable flow rate.

The options of stainless steel sanitary angle reducer filters include:

Filtration accuracy: filter screens or filter elements with different pore sizes to meet different particle filtration requirements.

Connection method: threaded connection, clamping or welding, suitable for different pipeline interfaces.

Material: different grades of stainless steel materials can be selected, such as 304, 316L, etc.

Cleaning method: manual cleaning or automatic backwashing function.

Filter type: Y-type, T-type or porous, etc., selected according to pipeline layout and needs.

Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

● The stainless steel sanitary angle reducer filter adopts a unique fluid distribution design, which optimizes the inlet distribution of the fluid through the angle structure.

● The internal flow channel of the stainless steel sanitary angle reducer filter has been finely designed, and a streamlined surface is adopted to reduce the turbulence and resistance of the fluid.

● The stainless steel sanitary angle reducer filter is designed with an adjustable filter element clamping system, which can adjust the tightness of the filter element according to the actual filtering needs to improve the filtering effect.

● The stainless steel sanitary angle reducer filter is equipped with a quick disassembly design, and the filter element and other internal components can be easily disassembled, which is convenient for quick cleaning and maintenance, reducing equipment downtime.

● The stainless steel sanitary angle reducer filter adopts a double sealing design. The inlet and outlet and cover of the filter are equipped with two layers of sealing rings, which further enhances the sealing performance and prevents leakage.

● The stainless steel sanitary angle reducer filter is equipped with an automatic backwashing function, which regularly backwashes the filter element through an intelligent control system to remove accumulated impurities.

Application

Stainless steel sanitary angle reducer filters are widely used in the following industries, food industry: ensure liquid filtration and prevent impurities from affecting food safety. Beverage industry: filter raw water and finished beverages to ensure product quality. Pharmaceutical industry: clean filtration to prevent impurities from contaminating drugs and production equipment. Chemical industry: filter chemicals to prevent particulate matter from affecting the reaction process. Dairy industry: ensure the cleanliness of dairy products to prevent impurities from affecting taste and quality. Water treatment industry: remove impurities in water to ensure clean water quality and stable system. Biotechnology industry: filter cell culture fluid to keep the culture environment pollution-free.