| Availability: | |

|---|---|

| Quantity: | |

JONENG

8481804090

Stainless Steel Sanitary Pipe Straight-through Sight Glass with Protective Cover

The stainless steel sanitary pipe straight-through sight glass with protective cover is designed to provide efficient fluid monitoring while ensuring the long-term durability of the equipment in harsh environments. Its unique protective cover design effectively prevents damage caused by external impact, corrosion or improper operation. Especially during the production process, the sight glass can observe the color, concentration or whether there are impurities in the fluid in real time, helping to detect abnormalities in time. Its hygienic stainless steel material and protective function make it suitable for the food, beverage and pharmaceutical industries with high cleanliness requirements, ensuring the safety of the production environment and the stability of the fluid process, thereby improving the reliability and efficiency of the entire production system.

Working Principles

The working principle of the stainless steel sanitary pipeline straight-through sight glass with protective cover is based on real-time monitoring of the fluid through the pipeline using a transparent observation window. First, the fluid enters the sight glass through the pipeline, and the observation window allows the operator to intuitively view the fluid status in the pipeline. Because the sight glass is equipped with a protective cover, it effectively prevents external impact or contamination from affecting the observation window. The flow, color, concentration and other characteristics of the fluid can be clearly presented through the sight glass window, helping to monitor whether the fluid meets the expected standards. If there are abnormal conditions (such as impurities or flow problems), the staff can take timely measures.

The options of the stainless steel sanitary pipeline straight-through sight glass with protective cover include:

Sight glass material: 304 or 316L stainless steel.

Observation window type: flat or curved window.

Lighting system: built-in LED lighting or without lighting.

Pressure/temperature sensor: with sensor to monitor pipeline pressure or temperature.

Protective cover design: transparent or metal protective cover.

Cleaning method: removable cleaning or automatic cleaning function.

Connection method: threaded connection or welding connection.

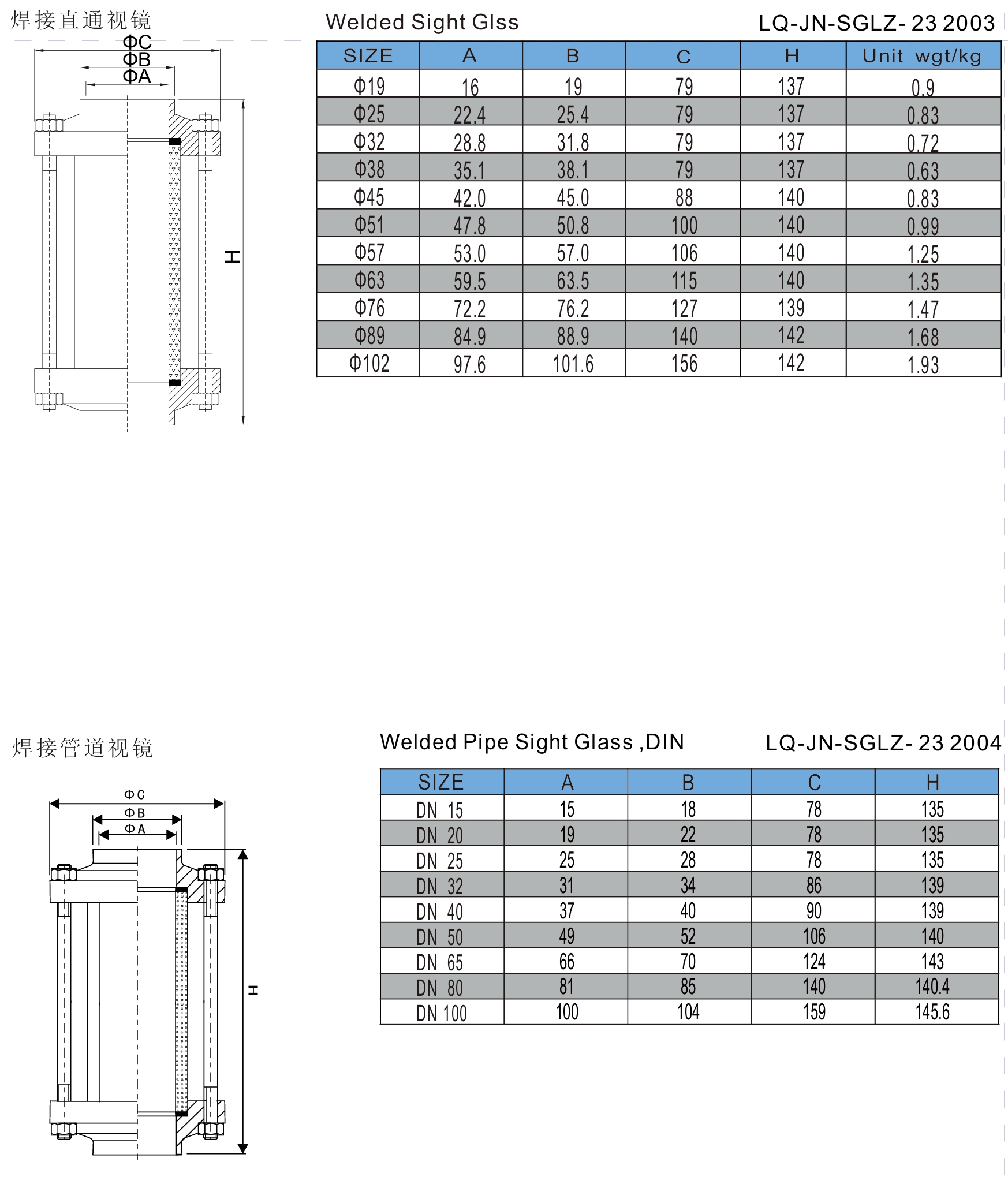

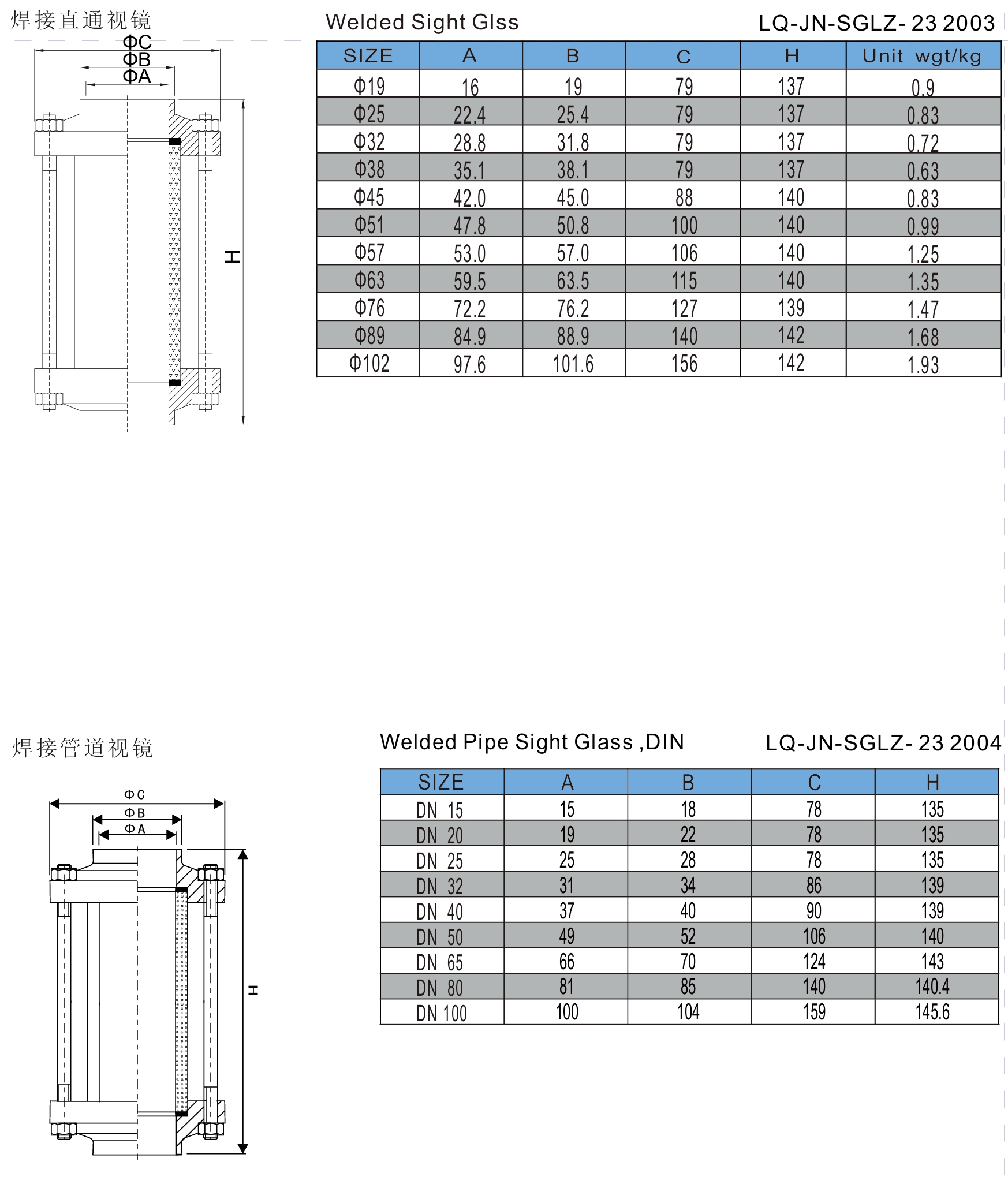

Specification Chart

Size | 1” to 6” |

End connections | Sanitary clamp, butt-weld, i-line or others on request. |

Guard | polycarbonate guard (protects from being broken or damaged) |

Seal material | PTFE, silicone,EPDM |

Studs and Nuts | AISI 304 |

| Flange | AISI304, AISI 316L |

Pressure | - up to 10 bar |

Temperature | - up to 250 F. |

Features

● The stainless steel sanitary pipe straight-through sight glass with protective cover adopts a special inner surface coating, which has anti-fouling and self-cleaning functions.

● The stainless steel sanitary pipe straight-through sight glass with protective cover has an integrated automatic temperature compensation system, which automatically adjusts the transparency of the sight glass window according to the temperature change of the fluid in the pipeline.

● The stainless steel sanitary pipe straight-through sight glass with protective cover uses a multi-layer heat insulation protective layer to avoid the influence of high-temperature fluid on the sight glass body.

● The stainless steel sanitary pipe straight-through sight glass with protective cover is equipped with an intelligent light sensing adjustment system, which automatically adjusts the brightness of the observation window according to the light intensity of the fluid in the pipeline.

● The stainless steel sanitary pipe straight-through sight glass with protective cover can effectively suppress the high-frequency vibration caused by the flow of pipeline fluid. The fixing method and structure of the sight glass can reduce the interference of vibration on the observation effect.

● The angle and position of the external protective cover of the stainless steel sanitary pipe straight-through sight glass with protective cover can be adjusted according to different pipeline layouts to meet different installation requirements.

Application

Stainless steel sanitary pipe straight-through sight glasses with protective covers are widely used in the following industries: Food industry: used to observe the flowing liquid to ensure that no impurities contaminate the food quality. Beverage industry: real-time monitoring of the beverage fluid state to ensure that the product is free of foreign matter. Pharmaceutical industry: ensure the fluid cleanliness during the drug production process to avoid impurity contamination. Chemical industry: observe the flow of chemicals to prevent harmful substances from affecting production safety. Dairy industry: monitor the flow of dairy products to prevent contaminants from entering the finished product. Water treatment industry: monitor the purified water flow to ensure that the water quality meets the standards.

··

Working Principles

The working principle of the stainless steel sanitary pipeline straight-through sight glass with protective cover is based on real-time monitoring of the fluid through the pipeline using a transparent observation window. First, the fluid enters the sight glass through the pipeline, and the observation window allows the operator to intuitively view the fluid status in the pipeline. Because the sight glass is equipped with a protective cover, it effectively prevents external impact or contamination from affecting the observation window. The flow, color, concentration and other characteristics of the fluid can be clearly presented through the sight glass window, helping to monitor whether the fluid meets the expected standards. If there are abnormal conditions (such as impurities or flow problems), the staff can take timely measures.

The options of the stainless steel sanitary pipeline straight-through sight glass with protective cover include:

Sight glass material: 304 or 316L stainless steel.

Observation window type: flat or curved window.

Lighting system: built-in LED lighting or without lighting.

Pressure/temperature sensor: with sensor to monitor pipeline pressure or temperature.

Protective cover design: transparent or metal protective cover.

Cleaning method: removable cleaning or automatic cleaning function.

Connection method: threaded connection or welding connection.

Specification Chart

Size | 1” to 6” |

End connections | Sanitary clamp, butt-weld, i-line or others on request. |

Guard | polycarbonate guard (protects from being broken or damaged) |

Seal material | PTFE, silicone,EPDM |

Studs and Nuts | AISI 304 |

| Flange | AISI304, AISI 316L |

Pressure | - up to 10 bar |

Temperature | - up to 250 F. |

Features

● The stainless steel sanitary pipe straight-through sight glass with protective cover adopts a special inner surface coating, which has anti-fouling and self-cleaning functions.

● The stainless steel sanitary pipe straight-through sight glass with protective cover has an integrated automatic temperature compensation system, which automatically adjusts the transparency of the sight glass window according to the temperature change of the fluid in the pipeline.

● The stainless steel sanitary pipe straight-through sight glass with protective cover uses a multi-layer heat insulation protective layer to avoid the influence of high-temperature fluid on the sight glass body.

● The stainless steel sanitary pipe straight-through sight glass with protective cover is equipped with an intelligent light sensing adjustment system, which automatically adjusts the brightness of the observation window according to the light intensity of the fluid in the pipeline.

● The stainless steel sanitary pipe straight-through sight glass with protective cover can effectively suppress the high-frequency vibration caused by the flow of pipeline fluid. The fixing method and structure of the sight glass can reduce the interference of vibration on the observation effect.

● The angle and position of the external protective cover of the stainless steel sanitary pipe straight-through sight glass with protective cover can be adjusted according to different pipeline layouts to meet different installation requirements.

Application

Stainless steel sanitary pipe straight-through sight glasses with protective covers are widely used in the following industries: Food industry: used to observe the flowing liquid to ensure that no impurities contaminate the food quality. Beverage industry: real-time monitoring of the beverage fluid state to ensure that the product is free of foreign matter. Pharmaceutical industry: ensure the fluid cleanliness during the drug production process to avoid impurity contamination. Chemical industry: observe the flow of chemicals to prevent harmful substances from affecting production safety. Dairy industry: monitor the flow of dairy products to prevent contaminants from entering the finished product. Water treatment industry: monitor the purified water flow to ensure that the water quality meets the standards.