| Availability: | |

|---|---|

| Quantity: | |

A device made to filter impurities, particles, pollutants or undesired particles out of a liquid or gas as it passes through a pipeline or tube. To guarantee the fluid’s cleanliness and quality, inline filters are frequency utilized in a variety of application.The line type filters can be used for filtering the solid particles in liquid . The inlet and outlet are in the same line. So it is widely used for pipeline.

JN-STJY-23 1001

JONENG

8421219990

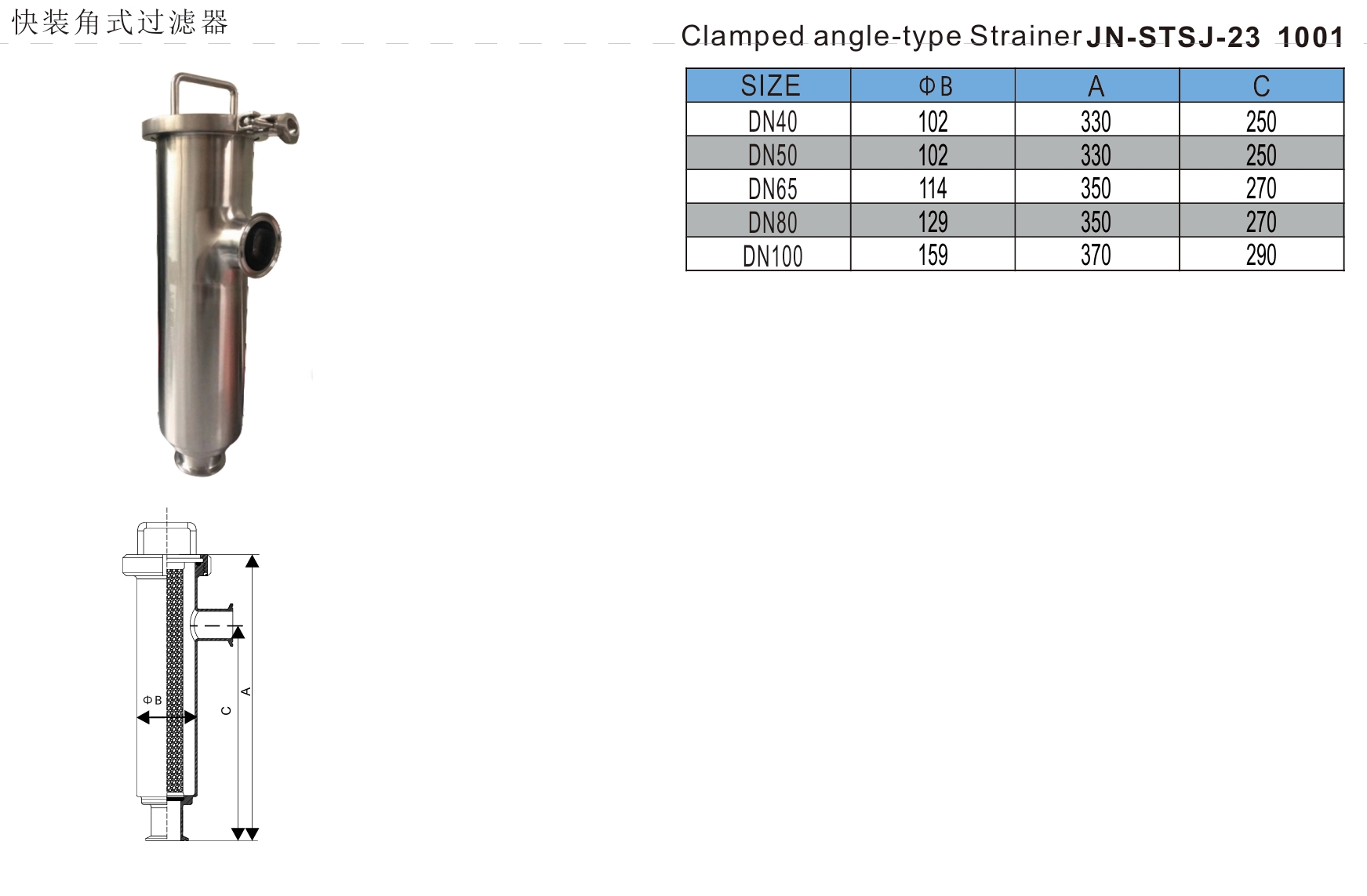

Top Flow Stainless Steel T L Straight Pipe Type Inline Strainer for Liquids Gases Filtration

These are essential component in systems where quality and cleanliness of the fluid are important. They contribute in maintaining the product quality, preventing equipment damage, and ensuring the safe and effective function of numerous processes and applications. This consists of a housing with inlet and outlet. The straining element is mounted in such a way that the flow forces through it. Thew element has a back up tube and straining mesh which is fixed by a rubber gasket between 2 flanges.

Working Principles

This works on a fairly simple principle, it filters and eliminates the pollutants by straining them through the mesh from liquid or gas while passing through the pipeline or tubing.

Stainless Steel Ln Line Filter Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

●Equipment protection, contaminant removal

●Product quality, improved system efficiency

●Customizability, health and safety

●Small pressure loss

●Good filtration

●Sealing ability

●Each cleaning

Application

This has various application in industries like water filtration and treatment plant, pharmaceutical and biotech, laboratory and research, chemical processing and others.

Working Principles

This works on a fairly simple principle, it filters and eliminates the pollutants by straining them through the mesh from liquid or gas while passing through the pipeline or tubing.

Feature and Specification

Stainless Steel Ln Line Filter Specification Chart

Size | 1” to 8” |

Material | AISI304, AISI316 |

Seals and gasket | PTFE, EPDM, silicon. Viton |

End connection | sanitary clamp, butt weld,threaded, union... |

Straining mesh | ¼ “ or 1/8” holes in backup tube 0.5mm,1.0mm,2.0mm,3.0mm,5.0mm,8.0mm.. |

Maximum pressure | up to 1.0mpa |

Maximum temperature | 120°c |

Max flow rate | 15T/H |

Features

●Equipment protection, contaminant removal

●Product quality, improved system efficiency

●Customizability, health and safety

●Small pressure loss

●Good filtration

●Sealing ability

●Each cleaning

Application

This has various application in industries like water filtration and treatment plant, pharmaceutical and biotech, laboratory and research, chemical processing and others.