| Availability: | |

|---|---|

| Quantity: | |

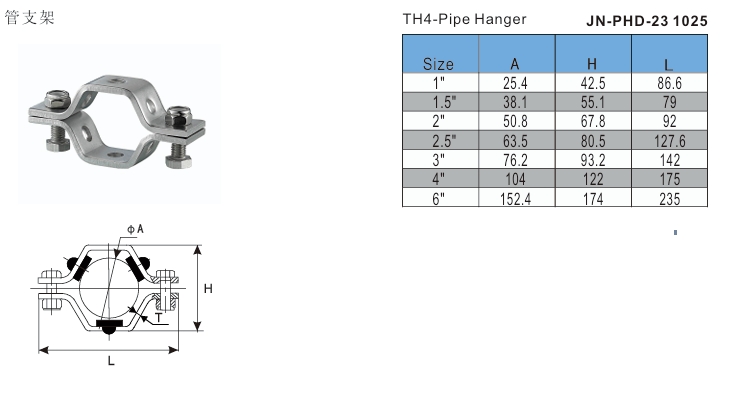

The stainless steel sanitary double-bolt hexagonal bracket is a fixed support device for pipeline systems in the food, pharmaceutical and other industries. The stainless steel sanitary double-bolt hexagonal bracket is mainly used in stainless steel pipeline systems in the food, pharmaceutical, chemical and other industries. It is usually installed at the support point, corner or place where a large load needs to be borne by the pipeline. According to the different designs and applications, the stainless steel sanitary double-bolt hexagonal bracket mainly has the following types: straight bracket, L-shaped bracket, U-shaped bracket, adjustable bracket, bracket with shock pad.

JONENG

8481804090

Stainless Steel Sanitary TriClamp Double Bolt Hexagon Bracket

The design goal of the stainless steel sanitary double-bolt hexagonal bracket is to ensure the stability and safety of the pipeline system under high hygiene standards. Its double-bolt structure enhances the firmness of the bracket, can withstand large pressure and temperature fluctuations, and prevents the pipeline from loosening or displacement, especially in the food, pharmaceutical, chemical and other industries, which often involve high temperature, high pressure or corrosive environment. The design takes into account easy cleaning to avoid bacterial growth. At the same time, the hexagonal bolts are easy to operate, which improves the convenience of installation and maintenance. The focus is on maintaining the long-term stable operation of the pipeline system while meeting strict hygiene and safety requirements.

Working Principles

The working principle of the stainless steel sanitary double bolt hexagonal bracket is to fix and support the pipeline through a double bolt structure. The bracket is installed at the support point or corner of the pipeline system to ensure the stability of the pipeline during operation. The hexagonal bolts are tightened with precise torque to ensure that the bracket is firmly connected to the pipeline to prevent the pipeline from loosening or displacement due to pressure, temperature fluctuations or vibration. The bracket usually has an adjustment function to adapt to the position of the pipeline so that it can be fine-tuned according to the needs of the site to ensure the long-term stable operation of the pipeline and resist the influence of the external environment.

The options of the stainless steel sanitary double bolt hexagonal bracket include:

Material selection: different grades of stainless steel (such as 304, 316L, etc.).

Size selection: adapt to pipelines of different diameters.

Surface treatment: such as polishing, brushing or sandblasting.

Shock pads: used to reduce vibration and protect pipelines.

Adjustable design: provides adjustment function for pipeline angle and position.

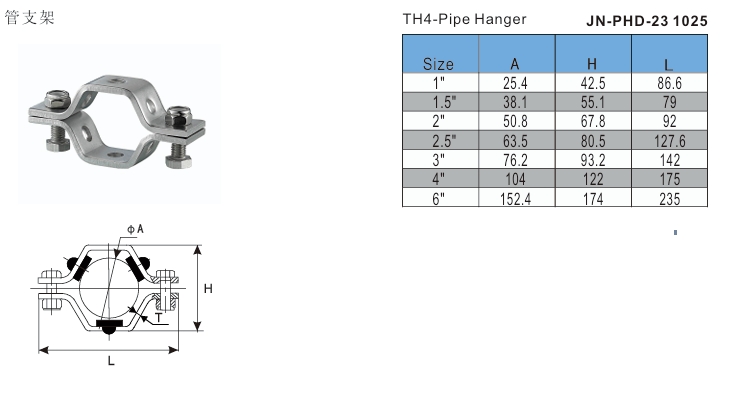

Specification Chart

Size | ½ " to 12 " |

Material | AISI 304,AISI201 |

Standard | DIN, SMS, ISO, 3A,AS,BS |

Production way | Pressed |

Made from sheets | |

Features

● The stainless steel sanitary double-bolt hexagonal bracket adopts high-precision thread cutting technology to ensure that the bolts and nuts are precisely matched and tightened reliably.

● The design of the stainless steel sanitary double-bolt hexagonal bracket is optimized based on fluid mechanics, and the structure of the pipeline support point is precisely calculated to reduce pipeline stress concentration and evenly distribute the load.

● The stainless steel sanitary double-bolt hexagonal bracket adopts special surface treatment technology, such as electrolytic polishing or nitriding treatment, to make the bracket surface smoother, reducing the possibility of tiny cracks and bacteria breeding.

● The stainless steel sanitary double-bolt hexagonal bracket is designed with elastic components that adapt to temperature changes, which can maintain stable connection when the temperature fluctuates violently.

● The support point design of the stainless steel sanitary double-bolt hexagonal bracket enables it to withstand higher loads than traditional brackets by thickening the steel and strengthening the structure.

● The stainless steel sanitary double-bolt hexagonal bracket is designed with an anti-vibration and noise reduction isolation layer inside, which can effectively isolate the vibration transmitted by the pipeline and reduce the impact of pipeline vibration on the surrounding environment.

Application

Stainless steel sanitary double bolt hexagonal bracket is widely used in the following industries, food industry: ensure the hygiene of the pipeline system and meet strict food safety standards. Pharmaceutical industry: Meet the high requirements for hygiene and stability in the drug production process. Chemical industry: Keep the pipeline system stable and safe in highly corrosive environments. Beverage production: Keep the production environment clean and avoid cross contamination. Biopharmaceuticals: Support high-pressure and high-temperature pipeline systems to ensure the stability of the pharmaceutical process. Medical devices: Keep the pipeline system clean to prevent bacterial growth. Dairy processing: Avoid pipeline contamination in dairy production and improve product quality.

Working Principles

The working principle of the stainless steel sanitary double bolt hexagonal bracket is to fix and support the pipeline through a double bolt structure. The bracket is installed at the support point or corner of the pipeline system to ensure the stability of the pipeline during operation. The hexagonal bolts are tightened with precise torque to ensure that the bracket is firmly connected to the pipeline to prevent the pipeline from loosening or displacement due to pressure, temperature fluctuations or vibration. The bracket usually has an adjustment function to adapt to the position of the pipeline so that it can be fine-tuned according to the needs of the site to ensure the long-term stable operation of the pipeline and resist the influence of the external environment.

The options of the stainless steel sanitary double bolt hexagonal bracket include:

Material selection: different grades of stainless steel (such as 304, 316L, etc.).

Size selection: adapt to pipelines of different diameters.

Surface treatment: such as polishing, brushing or sandblasting.

Shock pads: used to reduce vibration and protect pipelines.

Adjustable design: provides adjustment function for pipeline angle and position.

Specification Chart

Size | ½ " to 12 " |

Material | AISI 304,AISI201 |

Standard | DIN, SMS, ISO, 3A,AS,BS |

Production way | Pressed |

Made from sheets | |

Features

● The stainless steel sanitary double-bolt hexagonal bracket adopts high-precision thread cutting technology to ensure that the bolts and nuts are precisely matched and tightened reliably.

● The design of the stainless steel sanitary double-bolt hexagonal bracket is optimized based on fluid mechanics, and the structure of the pipeline support point is precisely calculated to reduce pipeline stress concentration and evenly distribute the load.

● The stainless steel sanitary double-bolt hexagonal bracket adopts special surface treatment technology, such as electrolytic polishing or nitriding treatment, to make the bracket surface smoother, reducing the possibility of tiny cracks and bacteria breeding.

● The stainless steel sanitary double-bolt hexagonal bracket is designed with elastic components that adapt to temperature changes, which can maintain stable connection when the temperature fluctuates violently.

● The support point design of the stainless steel sanitary double-bolt hexagonal bracket enables it to withstand higher loads than traditional brackets by thickening the steel and strengthening the structure.

● The stainless steel sanitary double-bolt hexagonal bracket is designed with an anti-vibration and noise reduction isolation layer inside, which can effectively isolate the vibration transmitted by the pipeline and reduce the impact of pipeline vibration on the surrounding environment.

Application

Stainless steel sanitary double bolt hexagonal bracket is widely used in the following industries, food industry: ensure the hygiene of the pipeline system and meet strict food safety standards. Pharmaceutical industry: Meet the high requirements for hygiene and stability in the drug production process. Chemical industry: Keep the pipeline system stable and safe in highly corrosive environments. Beverage production: Keep the production environment clean and avoid cross contamination. Biopharmaceuticals: Support high-pressure and high-temperature pipeline systems to ensure the stability of the pharmaceutical process. Medical devices: Keep the pipeline system clean to prevent bacterial growth. Dairy processing: Avoid pipeline contamination in dairy production and improve product quality.