| Availability: | |

|---|---|

| Quantity: | |

The stainless steel sanitary round pipe clamp bracket is a high-precision component used for stable fixing of pipeline systems. The stainless steel sanitary round pipe clamp bracket is mainly used in sanitary fluid conveying pipeline systems in industries such as food, pharmaceuticals, and bioengineering. It is usually installed at the support nodes, corners, vertical pipe sections, and locations with large vibrations of the pipeline. Near key control valves, pump outlets, and diversion points, it helps to reduce the impact of fluids, ensure the stable operation of the pipeline system, optimize the fluid flow state, and improve the durability and sanitation safety of the overall system. The stainless steel sanitary round pipe clamp bracket can be mainly divided into the following types: single-bolt pipe clamp bracket, double-bolt pipe clamp bracket, adjustable pipe clamp bracket, welded pipe clamp bracket, and quick-install pipe clamp bracket.

JONENG

8481804090

Stainless Steel Sanitary Round Pipe Clamp Bracket For Food

The stainless steel sanitary round pipe clamp bracket is not only a simple pipeline fixing device, but also a key support unit in a precision control system. It is designed to provide dynamic buffering while ensuring the stability of the pipeline to adapt to the influence of temperature changes, fluid pulses, and mechanical vibrations, and prevent fatigue damage caused by the accumulation of small stresses. At the same time, it optimizes the arrangement of pipelines to maximize space utilization and avoid increased maintenance costs due to cluttered pipelines. In addition, the bracket can also reduce the resonance caused by high-speed fluid flow and improve the silent operation of the system. In an environment with high sanitation requirements, its seamless polished surface prevents the accumulation of pollutants and ensures that the pipeline is clean for a long time.

Working Principles

The working principle of the stainless steel sanitary round pipe clamp bracket is based on the combined effect of mechanical fixation, force dispersion and anti-seismic buffering to ensure the stability of the pipeline, balanced force and reduce the impact of vibration. First, the clamping structure of the bracket fixes the pipeline to the support point by bolts, quick-release buckles or welding to limit its radial and axial displacement. Secondly, the arc-shaped clamping surface of the bracket fits tightly with the outer wall of the pipeline, so that the weight of the pipeline is evenly distributed, preventing local stress concentration from causing deformation or fatigue damage to the pipeline. During the fluid transportation process, the pipeline may produce slight vibrations due to medium flow, pump pulses or environmental vibrations. The shock-proof bracket absorbs part of the vibration through rubber pads or elastic buffer structures, reduces noise, and protects the pipeline from fatigue impact.

The options of the stainless steel sanitary round pipe clamp bracket include:

Material: 304 or 316L stainless steel, to meet different corrosion resistance requirements.

Size: Various diameters to suit different pipe sizes.

Surface treatment: Electrolytic polishing or mirror polishing to improve hygiene.

Installation: Bolt-on, welding or snap-on installation.

Gasket material: EPDM, silicone or PTFE gasket to suit different media and temperatures.

Anti-corrosion coating: Optional Teflon coating to enhance corrosion resistance.

Certification standards: Comply with international hygiene certifications such as 3A, FDA, and EHEDG.

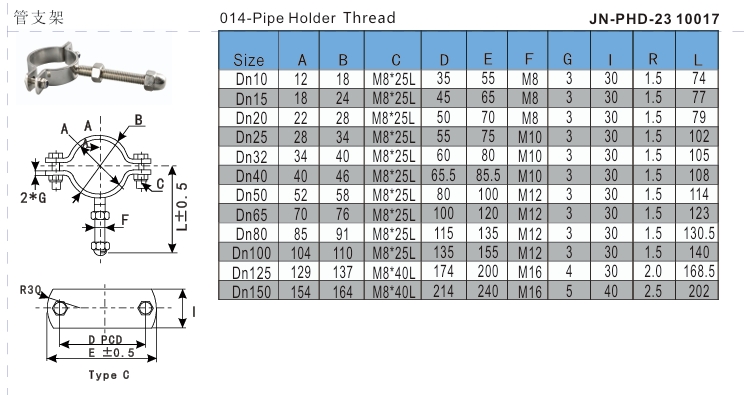

Specification Chart

Size | ½ " to 12 " |

Material | AISI 304,AISI201 |

Standard | DIN, SMS, ISO, 3A,AS,BS |

Production way | Pressed |

Made from sheets | |

Features

● The stainless steel sanitary round pipe clamp bracket adopts micron-level electrolytic polishing technology to precisely polish the inner wall of the valve body to form a super-mirror seamless structure, which effectively inhibits the attachment of microorganisms and maintains a sterile environment.

● The stainless steel sanitary round pipe clamp bracket introduces an integrated pneumatic feedback system to monitor the status of the bracket in real time, collects data through micro sensors, and realizes remote diagnosis and early warning.

● The stainless steel sanitary round pipe clamp bracket adopts a modular design structure and standardized production of various components, which is convenient for rapid assembly, disassembly and maintenance.

● The stainless steel sanitary round pipe clamp bracket uses anti-vibration and vibration reduction technology to integrate rubber buffer pads to absorb equipment vibration and shock and disperse local stress concentration.

● The stainless steel sanitary round pipe clamp bracket adopts anti-corrosion surface treatment technology to fully protect the bracket from acid and alkali erosion, delay aging loss, and ensure that the pipeline is in a high clean state for a long time.

● The stainless steel sanitary round pipe clamp bracket has a built-in guide slide design, which allows the pipeline to be adjusted by micro displacement, adapt to thermal expansion and contraction changes, and prevent stress concentration from causing pipeline damage.

Application

Stainless steel sanitary round pipe clamp brackets are widely used in the following industries: Food processing industry: Pipeline fixation to ensure a hygienic and sterile production environment. Dairy industry: Connecting delivery pipelines to ensure the stability of liquid delivery. Pharmaceutical industry: Maintain clean pipelines to meet GMP aseptic standards. Beverage production industry: Secure the delivery pipeline to ensure contamination-free delivery of fluids. Biotechnology industry: Fix the experimental pipeline to ensure the precise operation of the fluid system. Cosmetics industry: Connect sanitary pipelines to ensure pure and contaminant-free products. Beer brewing industry: Secure the fermentation tank pipeline to prevent vibration from affecting quality.

Working Principles

The working principle of the stainless steel sanitary round pipe clamp bracket is based on the combined effect of mechanical fixation, force dispersion and anti-seismic buffering to ensure the stability of the pipeline, balanced force and reduce the impact of vibration. First, the clamping structure of the bracket fixes the pipeline to the support point by bolts, quick-release buckles or welding to limit its radial and axial displacement. Secondly, the arc-shaped clamping surface of the bracket fits tightly with the outer wall of the pipeline, so that the weight of the pipeline is evenly distributed, preventing local stress concentration from causing deformation or fatigue damage to the pipeline. During the fluid transportation process, the pipeline may produce slight vibrations due to medium flow, pump pulses or environmental vibrations. The shock-proof bracket absorbs part of the vibration through rubber pads or elastic buffer structures, reduces noise, and protects the pipeline from fatigue impact.

The options of the stainless steel sanitary round pipe clamp bracket include:

Material: 304 or 316L stainless steel, to meet different corrosion resistance requirements.

Size: Various diameters to suit different pipe sizes.

Surface treatment: Electrolytic polishing or mirror polishing to improve hygiene.

Installation: Bolt-on, welding or snap-on installation.

Gasket material: EPDM, silicone or PTFE gasket to suit different media and temperatures.

Anti-corrosion coating: Optional Teflon coating to enhance corrosion resistance.

Certification standards: Comply with international hygiene certifications such as 3A, FDA, and EHEDG.

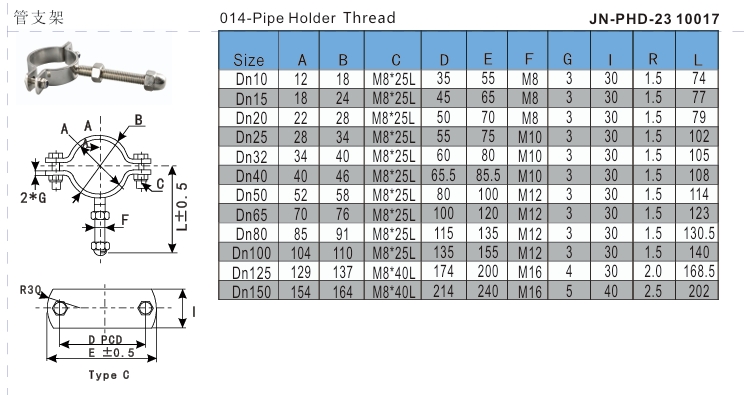

Specification Chart

Size | ½ " to 12 " |

Material | AISI 304,AISI201 |

Standard | DIN, SMS, ISO, 3A,AS,BS |

Production way | Pressed |

Made from sheets | |

Features

● The stainless steel sanitary round pipe clamp bracket adopts micron-level electrolytic polishing technology to precisely polish the inner wall of the valve body to form a super-mirror seamless structure, which effectively inhibits the attachment of microorganisms and maintains a sterile environment.

● The stainless steel sanitary round pipe clamp bracket introduces an integrated pneumatic feedback system to monitor the status of the bracket in real time, collects data through micro sensors, and realizes remote diagnosis and early warning.

● The stainless steel sanitary round pipe clamp bracket adopts a modular design structure and standardized production of various components, which is convenient for rapid assembly, disassembly and maintenance.

● The stainless steel sanitary round pipe clamp bracket uses anti-vibration and vibration reduction technology to integrate rubber buffer pads to absorb equipment vibration and shock and disperse local stress concentration.

● The stainless steel sanitary round pipe clamp bracket adopts anti-corrosion surface treatment technology to fully protect the bracket from acid and alkali erosion, delay aging loss, and ensure that the pipeline is in a high clean state for a long time.

● The stainless steel sanitary round pipe clamp bracket has a built-in guide slide design, which allows the pipeline to be adjusted by micro displacement, adapt to thermal expansion and contraction changes, and prevent stress concentration from causing pipeline damage.

Application

Stainless steel sanitary round pipe clamp brackets are widely used in the following industries: Food processing industry: Pipeline fixation to ensure a hygienic and sterile production environment. Dairy industry: Connecting delivery pipelines to ensure the stability of liquid delivery. Pharmaceutical industry: Maintain clean pipelines to meet GMP aseptic standards. Beverage production industry: Secure the delivery pipeline to ensure contamination-free delivery of fluids. Biotechnology industry: Fix the experimental pipeline to ensure the precise operation of the fluid system. Cosmetics industry: Connect sanitary pipelines to ensure pure and contaminant-free products. Beer brewing industry: Secure the fermentation tank pipeline to prevent vibration from affecting quality.