| Availability: | |

|---|---|

| Quantity: | |

JN-DPHV-23 1008-BJ

JONENG

84818040900

Stainless Steel Hygienic Polished Weld on Ferrule Connector

The stainless steel sanitary ferrule adapter is designed to provide a safe and reliable pipe connection solution under extremely high hygiene requirements. It can effectively cope with the pressure, temperature and corrosiveness during fluid transportation, ensure the seamless connection and sealing of pipe systems of different specifications, and avoid liquid leakage or external contamination. At the same time, the design fully considers the easy cleaning and durability, adapts to the high standards of the food, pharmaceutical and other industries, ensures that the fluid circulates in a pollution-free environment, and avoids any impact on the quality and safety of the final product.

Working Principles

The working principle of the stainless steel sanitary ferrule adapter relies on its unique sealing and connection mechanism. Its core function is to ensure the stability and leak-free of the fluid delivery system through the precise fit between the ferrule and the pipe interface. When the stainless steel sanitary ferrule adapter is docked with the pipe interface, the sealing ring will be compressed to form a solid sealing surface to prevent the leakage of fluid or gas. This sealing effect can be stably maintained when the fluid pressure in the pipe changes, ensuring that the seal is not affected. The use of stainless steel sanitary ferrule adapters can provide a safe and reliable connection solution for the pipeline system, ensuring the stability and hygiene of fluid delivery.

The options of stainless steel sanitary ferrule adapters include:

Material: 304 or 316L stainless steel to meet different corrosion resistance requirements.

Size: a variety of calibers (such as 1/2"~6"), suitable for different pipes.

Sealing ring: EPDM, FKM, silicone, etc., with different temperature and chemical resistance.

Surface treatment: electrolytic polishing (Ra≤0.8μm) or mechanical polishing to improve the hygiene level.

Connection method: Tri-Clamp, DIN, SMS and other standards, compatible with different systems.

Customized design: non-standard size, special angle (such as 45°, 90°elbow) or enhanced pressure-resistant structure.

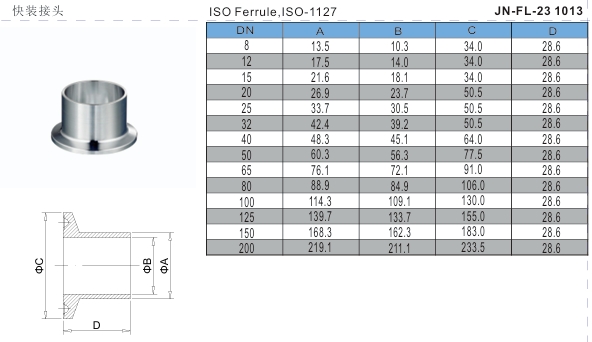

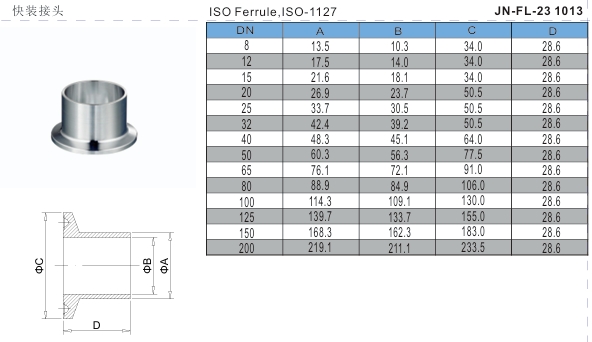

Specification Chart

Size range | 1/2”- 12” |

Material | -ASI304 or 316L |

Gasket/Seal Material | EPDM, NBR, VITION, SILICONE |

Working Pressure | 6 - 20bar |

Working Temperature | 20°C ~ +150°C |

Connection End | Weld, Clamp, Union, Flange,male threaded, female threaded |

Connection Standards | DIN, SMS, 3A, ISO, RJT, BSM, IDF |

Features

● The stainless steel sanitary ferrule adapter adopts double-layer sealing technology, and multiple sealing rings are set on the sealing surface to ensure more effective prevention of leakage.

● The connection surface of the stainless steel sanitary ferrule adapter is processed with high precision to ensure the tightness of the sealing and connection, reducing the risk of leakage or gas penetration.

● The surface of the stainless steel sanitary ferrule adapter is specially polished to ensure that there are no burrs and rough surfaces, avoid liquid accumulation and dirt adhesion, and meet hygiene requirements.

● The stainless steel sanitary ferrule adapter adopts a specially designed quick connection mechanism, which makes installation and disassembly more convenient, saving time and labor costs.

● The stainless steel sanitary ferrule adapter is equipped with an adjustable fastening thread system, which can adjust the fastening force according to the pressure and demand of the pipeline connection to ensure stability.

● The design of the stainless steel sanitary ferrule adapter takes into account the vibration that may be generated during the operation of the equipment, and adopts a shockproof design to effectively avoid loose connections.

Application

Stainless steel sanitary ferrule adapters are used in the following industries: Food industry: ensure the sealing and connection safety of food liquid delivery pipelines. Pharmaceutical industry: used for pipeline connections between pharmaceutical equipment to ensure hygiene and sealing. Beverage industry: ensure the sealing and corrosion resistance of pipeline connections during beverage production. Chemical industry: adapt to chemical delivery pipelines to prevent leakage and contamination. Biological products industry: used for biological products equipment connection to ensure no pollution and tight sealing. Water treatment industry: provides stable sealing to prevent leakage problems in water treatment systems.

Working Principles

The working principle of the stainless steel sanitary ferrule adapter relies on its unique sealing and connection mechanism. Its core function is to ensure the stability and leak-free of the fluid delivery system through the precise fit between the ferrule and the pipe interface. When the stainless steel sanitary ferrule adapter is docked with the pipe interface, the sealing ring will be compressed to form a solid sealing surface to prevent the leakage of fluid or gas. This sealing effect can be stably maintained when the fluid pressure in the pipe changes, ensuring that the seal is not affected. The use of stainless steel sanitary ferrule adapters can provide a safe and reliable connection solution for the pipeline system, ensuring the stability and hygiene of fluid delivery.

The options of stainless steel sanitary ferrule adapters include:

Material: 304 or 316L stainless steel to meet different corrosion resistance requirements.

Size: a variety of calibers (such as 1/2"~6"), suitable for different pipes.

Sealing ring: EPDM, FKM, silicone, etc., with different temperature and chemical resistance.

Surface treatment: electrolytic polishing (Ra≤0.8μm) or mechanical polishing to improve the hygiene level.

Connection method: Tri-Clamp, DIN, SMS and other standards, compatible with different systems.

Customized design: non-standard size, special angle (such as 45°, 90°elbow) or enhanced pressure-resistant structure.

Specification Chart

Size range | 1/2”- 12” |

Material | -ASI304 or 316L |

Gasket/Seal Material | EPDM, NBR, VITION, SILICONE |

Working Pressure | 6 - 20bar |

Working Temperature | 20°C ~ +150°C |

Connection End | Weld, Clamp, Union, Flange,male threaded, female threaded |

ConnectionStandards | DIN, SMS, 3A, ISO, RJT, BSM, IDF |

Features

● The stainless steel sanitary ferrule adapter adopts double-layer sealing technology, and multiple sealing rings are set on the sealing surface to ensure more effective prevention of leakage.

● The connection surface of the stainless steel sanitary ferrule adapter is processed with high precision to ensure the tightness of the sealing and connection, reducing the risk of leakage or gas penetration.

● The surface of the stainless steel sanitary ferrule adapter is specially polished to ensure that there are no burrs and rough surfaces, avoid liquid accumulation and dirt adhesion, and meet hygiene requirements.

● The stainless steel sanitary ferrule adapter adopts a specially designed quick connection mechanism, which makes installation and disassembly more convenient, saving time and labor costs.

● The stainless steel sanitary ferrule adapter is equipped with an adjustable fastening thread system, which can adjust the fastening force according to the pressure and demand of the pipeline connection to ensure stability.

● The design of the stainless steel sanitary ferrule adapter takes into account the vibration that may be generated during the operation of the equipment, and adopts a shockproof design to effectively avoid loose connections.

Application

Stainless steel sanitary ferrule adapters are used in the following industries: Food industry: ensure the sealing and connection safety of food liquid delivery pipelines. Pharmaceutical industry: used for pipeline connections between pharmaceutical equipment to ensure hygiene and sealing. Beverage industry: ensure the sealing and corrosion resistance of pipeline connections during beverage production. Chemical industry: adapt to chemical delivery pipelines to prevent leakage and contamination. Biological products industry: used for biological products equipment connection to ensure no pollution and tight sealing. Water treatment industry: provides stable sealing to prevent leakage problems in water treatment systems.