| Availability: | |

|---|---|

| Quantity: | |

JN-DPHV-23 1008-BJ

JONENG

84818040900

Stainless Steel Sanitary DN15 Polished Threaded Ferrule Fitting

The purpose of the design of stainless steel sanitary ferrule joints is to ensure the sealing and sanitary safety of the pipe system during fluid transportation. It can effectively prevent liquid leakage and prevent external pollutants from entering the system without affecting the normal flow of the fluid. The joint is made of stainless steel and has the characteristics of corrosion resistance and high temperature resistance. It can be used for a long time in a high-demand sanitary environment. Its unique ferrule design can ensure tight connection, easy disassembly, easy cleaning and maintenance, and meets CIP and SIP standards, ensuring that the pipe system always maintains a high standard of hygiene.

Working Principles

The working principle of the stainless steel sanitary ferrule joint is based on its tight mechanical connection and sealing design. When the ferrule joint is installed in the pipeline system, the ferrule and the end of the pipe are tightly matched to form a reliable seal. The specific steps are: first, insert the pipes at both ends of the joint into the ferrule groove of the joint; then, fix the joint by thread, clamp or welding to ensure its firm connection; then, the sealing ring of the joint expands under the pressure of the pipeline, further enhancing the sealing performance and preventing fluid leakage; finally, the entire system can safely and stably transmit liquid.

The options of stainless steel sanitary ferrule joints include:

Connection method: quick installation, thread, welding, flange.

Sealing material: silicone, EPDM, PTFE, etc.

Size: multiple pipe diameters are available.

Surface treatment: internal and external polishing, mirror polishing.

Pressure level: adapted to different pressure ranges.

Accessories: accessories such as drain ports and additional clamps can be selected.

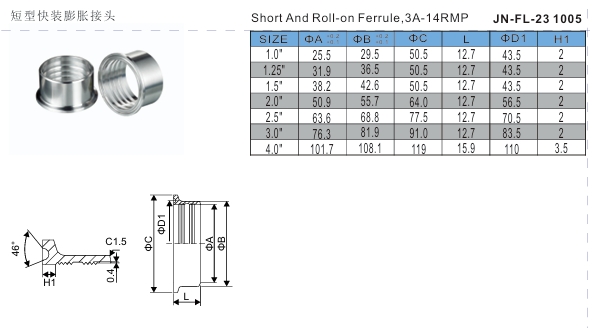

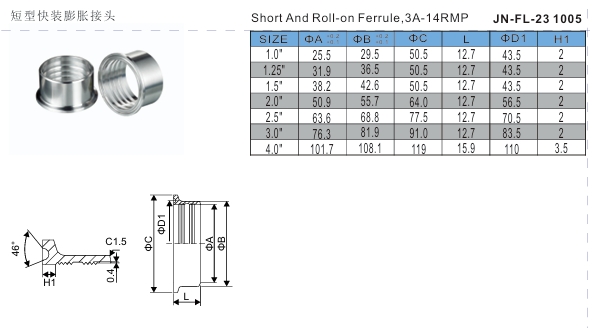

Specification Chart

Size range | 1/2”- 12” |

Material | -ASI304 or 316L |

Gasket/Seal Material | EPDM, NBR, VITION, SILICONE |

Working Pressure | 6 - 20bar |

Working Temperature | 20°C ~ +150°C |

Connection End | Weld, Clamp, Union, Flange,male threaded, female threaded |

Connection Standards | DIN, SMS, 3A, ISO, RJT, BSM, IDF |

Features

● The stainless steel sanitary ferrule joint adopts a multi-layer composite sealing design, and the sealing rings of various materials are superimposed inside to ensure that it can maintain a long-lasting seal even under high pressure and extreme environments.

● The stainless steel sanitary ferrule joint adopts reverse sealing technology, and the sealing ring is designed as a reverse structure, so that when the joint is under pressure, the sealing ring is prevented from deforming and failing under high pressure.

● The stainless steel sanitary ferrule joint is designed with a threadless clamping ring, which is in close contact with the pipeline through mechanical locking, and the connection can be completed quickly without external tools.

● The stainless steel sanitary ferrule joint has a built-in pressure regulating valve, which can automatically adjust the sealing effect according to the fluid pressure in the pipeline to ensure the best sealing performance under different fluid pressures.

● The inner wall of the stainless steel sanitary ferrule joint adopts a special self-cleaning coating, which can automatically remove tiny particles in the pipeline every time the fluid flows, reduce dirt accumulation, and keep the pipeline clean.

● The stainless steel sanitary ferrule joint is designed with an anti-impact structure inside, which protects the sealing ring and connecting parts from damage by absorbing the impact force of the fluid in the pipeline, and prolongs the service life.

Application

Stainless steel sanitary ferrule joints are widely used in the following industries, food and beverage industry: connecting pipeline equipment to ensure hygiene and pollution-free. Pharmaceutical industry: sealed delivery of liquid medicine in GMP clean systems. Bioengineering: Connecting fermentation tanks and other equipment in a sterile environment. Cosmetics industry: Sanitary pipe connections to avoid product contamination. Dairy industry: Sealed connections for milk and yogurt production lines. Winemaking industry: High-sanitary standard connections for wine delivery pipelines. Chemical industry: Rapid disassembly and assembly of corrosion-resistant medium pipelines. Water treatment industry: Sealed connections for purified water and ultrapure water pipelines.

Working Principles

The working principle of the stainless steel sanitary ferrule joint is based on its tight mechanical connection and sealing design. When the ferrule joint is installed in the pipeline system, the ferrule and the end of the pipe are tightly matched to form a reliable seal. The specific steps are: first, insert the pipes at both ends of the joint into the ferrule groove of the joint; then, fix the joint by thread, clamp or welding to ensure its firm connection; then, the sealing ring of the joint expands under the pressure of the pipeline, further enhancing the sealing performance and preventing fluid leakage; finally, the entire system can safely and stably transmit liquid.

The options of stainless steel sanitary ferrule joints include:

Connection method: quick installation, thread, welding, flange.

Sealing material: silicone, EPDM, PTFE, etc.

Size: multiple pipe diameters are available.

Surface treatment: internal and external polishing, mirror polishing.

Pressure level: adapted to different pressure ranges.

Accessories: accessories such as drain ports and additional clamps can be selected.

Specification Chart

Size range | 1/2”- 12” |

Material | -ASI304 or 316L |

Gasket/Seal Material | EPDM, NBR, VITION, SILICONE |

Working Pressure | 6 - 20bar |

Working Temperature | 20°C ~ +150°C |

Connection End | Weld, Clamp, Union, Flange,male threaded, female threaded |

ConnectionStandards | DIN, SMS, 3A, ISO, RJT, BSM, IDF |

Features

● The stainless steel sanitary ferrule joint adopts a multi-layer composite sealing design, and the sealing rings of various materials are superimposed inside to ensure that it can maintain a long-lasting seal even under high pressure and extreme environments.

● The stainless steel sanitary ferrule joint adopts reverse sealing technology, and the sealing ring is designed as a reverse structure, so that when the joint is under pressure, the sealing ring is prevented from deforming and failing under high pressure.

● The stainless steel sanitary ferrule joint is designed with a threadless clamping ring, which is in close contact with the pipeline through mechanical locking, and the connection can be completed quickly without external tools.

● The stainless steel sanitary ferrule joint has a built-in pressure regulating valve, which can automatically adjust the sealing effect according to the fluid pressure in the pipeline to ensure the best sealing performance under different fluid pressures.

● The inner wall of the stainless steel sanitary ferrule joint adopts a special self-cleaning coating, which can automatically remove tiny particles in the pipeline every time the fluid flows, reduce dirt accumulation, and keep the pipeline clean.

● The stainless steel sanitary ferrule joint is designed with an anti-impact structure inside, which protects the sealing ring and connecting parts from damage by absorbing the impact force of the fluid in the pipeline, and prolongs the service life.

Application

Stainless steel sanitary ferrule joints are widely used in the following industries, food and beverage industry: connecting pipeline equipment to ensure hygiene and pollution-free. Pharmaceutical industry: sealed delivery of liquid medicine in GMP clean systems. Bioengineering: Connecting fermentation tanks and other equipment in a sterile environment. Cosmetics industry: Sanitary pipe connections to avoid product contamination. Dairy industry: Sealed connections for milk and yogurt production lines. Winemaking industry: High-sanitary standard connections for wine delivery pipelines. Chemical industry: Rapid disassembly and assembly of corrosion-resistant medium pipelines. Water treatment industry: Sealed connections for purified water and ultrapure water pipelines.