| Availability: | |

|---|---|

| Quantity: | |

Sanitary Stainless Steel Three-piece Pneumatic Tank Bottom Valve is a hygienic discharge valve installed at the lowest point of tanks. Its three-piece body structure allows easy maintenance, while pneumatic actuation ensures precise, automated control and clean operation in sanitary processing systems

JONENG

Sanitary Stainless Steel Three-piece Pneumatic Tank Bottom Valve

Sanitary Stainless Steel Three-piece Pneumatic Tank Bottom Valve is a hygienic discharge valve installed at the lowest point of tanks. Its three-piece body structure allows easy maintenance, while pneumatic actuation ensures precise, automated control and clean operation in sanitary processing systems

Working Principles

The working principle of a Sanitary Stainless Steel Three-piece Pneumatic Tank Bottom Valve is based on compressed air driving a pneumatic actuator to control the valve stem movement. When air is supplied to the actuator, the internal piston moves linearly, lifting the valve core away from the seat and opening the flow path at the tank bottom. Process media then discharges smoothly by gravity and pressure. When the air supply is switched or released, the actuator returns the piston to its original position, pressing the valve core tightly against the seat to form a secure seal. The three-piece body design allows precise alignment of internal components, ensuring stable operation, easy disassembly, and reliable performance during repeated cleaning and production cycles

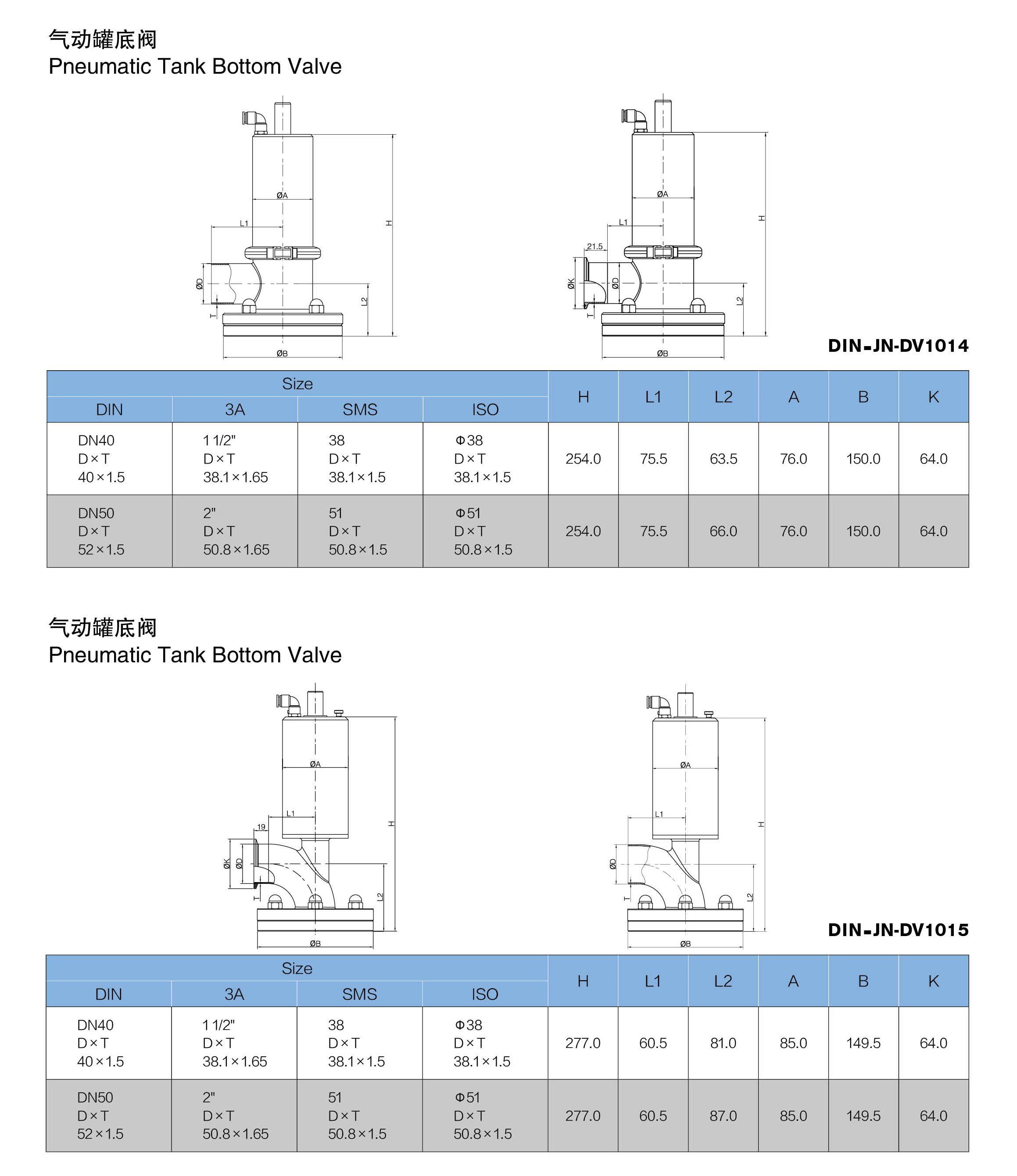

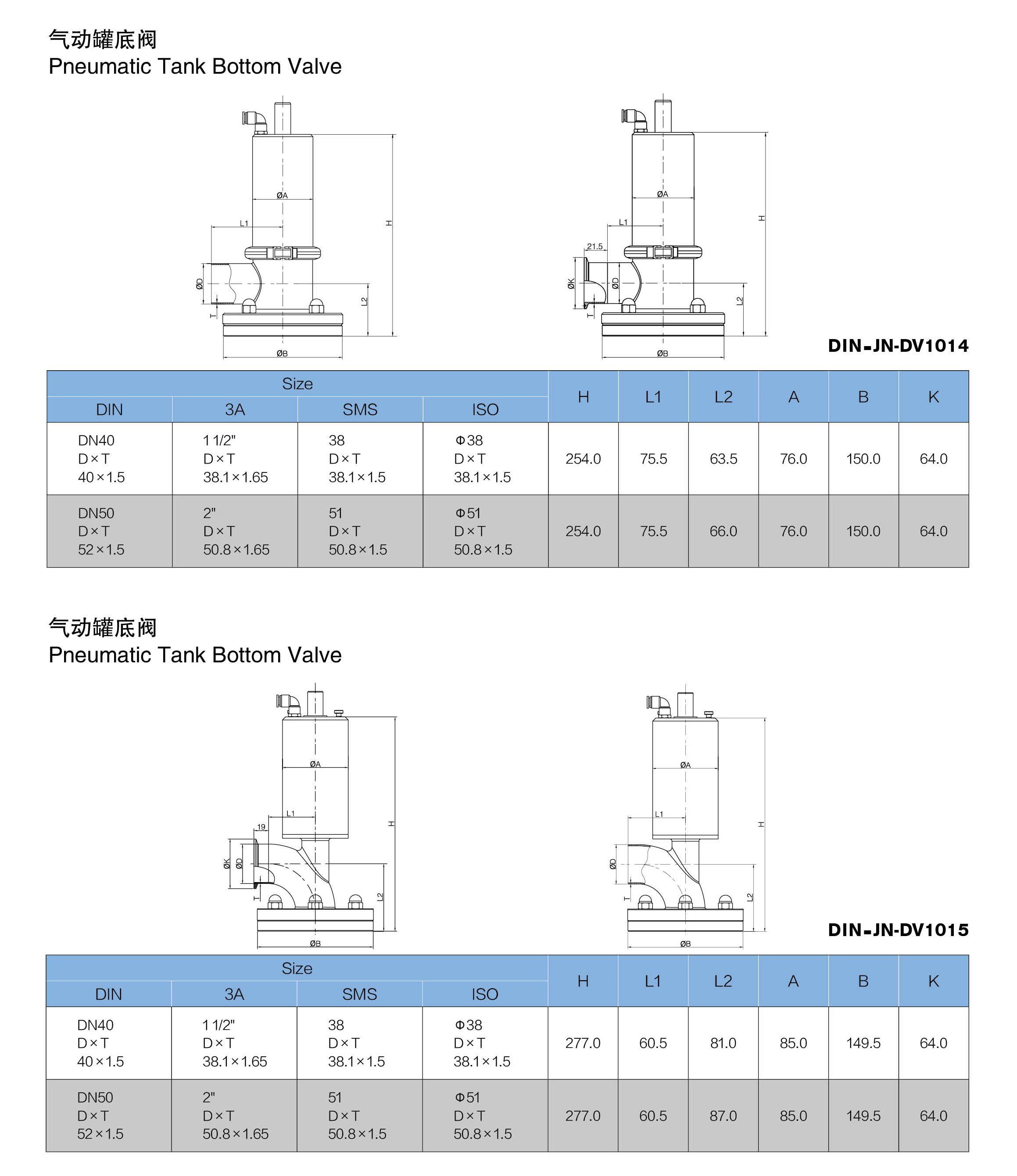

Stainless Steel Pipe Holder Specification Chart

Valve Size | Standard sizes: 1/2"-4" (corresponding to nominal diameter DN10-DN100); customized versions can be extended to DN125. Common specification range for special working conditions: 1"-4" (DN25-DN100). |

Connection Type | Mainstream: clamp connection; also supports thread, welding, and flange connections. Compatible with industry standard interfaces such as DN, SMS, ISO, IDF, RJT, and ASME BPE to meet different pipeline assembly needs. |

Operating Pressure Range | Regular working conditions: 0-1.0MPa (10bar); customized versions with special sealing materials and temperature adaptability can be extended to 1.0-3.0MPa (10-30bar). |

Constant Pressure Range | Recommended long-term constant working pressure: ≤1.0MPa (ensures stable sealing performance and service life). For higher constant pressure, enhanced seals and manufacturer's working condition verification are required. |

| Operating Temperature | Varies with sealing materials: -20℃-130℃ (standard PTFE seal); optional standard version: -30℃-150℃; customized high-temperature resistant version: -30℃-200℃. |

| Control Type | Mainly stainless steel electric/pneumatic actuator control. Achieves automatic control via 4-20mA/0-10V input signal, with non-holding feature for automatic reset after power failure. Compatible with manual control for mode switching. |

| Surface Treatment | Valve body: polished finish (standard precision Ra≤0.8μm); customized hygienic-grade versions (for pharmaceutical/food industries): Ra≤0.3μm, ensuring no medium residue dead ends and compliance with hygiene standards. |

| Sealing Material | Mainstream: PTFE (polytetrafluoroethylene); optional materials: TFM, PTFE+carbon fiber, PEEK. Gasket seals mostly meet FDA 177.2600 standard, suitable for hygienic working conditions. |

| Valve Body Material | Mainly 304 stainless steel (1.4301), 316L stainless steel (1.4404); high-end hygienic scenarios (e.g., biopharmaceuticals): ASME BPE 316L (1.4435) for higher purity and corrosion resistance requirements. |

| Cleaning Compatibility | Features non-retention flow channel design, supporting CIP (Clean-in-Place) and SIP (Sterilize-in-Place) with high-temperature steam cleaning. Complies with 3-A and FDA hygiene certifications, no medium residue dead ends, suitable for high-cleanliness standards in food, pharmaceutical, and cosmetic industries. |

Features

Features a three-piece body design that allows easy disassembly and maintenance without removing the entire valve from the tank.

Pneumatic actuation provides fast, precise, and automated opening and closing, improving process efficiency and operational safety.

Constructed from high-grade stainless steel with polished internal surfaces, ensuring excellent corrosion resistance and compliance with sanitary standards.

Tank bottom installation enables complete drainage by gravity, minimizing residue and preventing cross-contamination during production.

Reliable sealing mechanism ensures leak-free performance, supporting repeated cleaning cycles and maintaining consistent hygienic operation in process lines

Application

Sanitary Stainless Steel Three-piece Pneumatic Tank Bottom Valves are widely used in dairy and beverage industries for emptying milk, juice, or other liquid products from storage or mixing tanks. They are also applied in pharmaceutical and biotechnology production, where automated, hygienic discharge of sterile liquids or intermediates is critical. Additionally, these valves are suitable for food processing and cosmetic manufacturing, providing reliable tank drainage, easy cleaning, and integration into fully automated production lines to maintain product quality and process hygiene

Working Principles

The working principle of a Sanitary Stainless Steel Three-piece Pneumatic Tank Bottom Valve is based on compressed air driving a pneumatic actuator to control the valve stem movement. When air is supplied to the actuator, the internal piston moves linearly, lifting the valve core away from the seat and opening the flow path at the tank bottom. Process media then discharges smoothly by gravity and pressure. When the air supply is switched or released, the actuator returns the piston to its original position, pressing the valve core tightly against the seat to form a secure seal. The three-piece body design allows precise alignment of internal components, ensuring stable operation, easy disassembly, and reliable performance during repeated cleaning and production cycles

Feature and Specification

Stainless Steel Pipe Holder Specification Chart

Valve Size | Standard sizes: 1/2"-4" (corresponding to nominal diameter DN10-DN100); customized versions can be extended to DN125. Common specification range for special working conditions: 1"-4" (DN25-DN100). |

Connection Type | Mainstream: clamp connection; also supports thread, welding, and flange connections. Compatible with industry standard interfaces such as DN, SMS, ISO, IDF, RJT, and ASME BPE to meet different pipeline assembly needs. |

Operating Pressure Range | Regular working conditions: 0-1.0MPa (10bar); customized versions with special sealing materials and temperature adaptability can be extended to 1.0-3.0MPa (10-30bar). |

Constant Pressure Range | Recommended long-term constant working pressure: ≤1.0MPa (ensures stable sealing performance and service life). For higher constant pressure, enhanced seals and manufacturer's working condition verification are required. |

| Operating Temperature | Varies with sealing materials: -20℃-130℃ (standard PTFE seal); optional standard version: -30℃-150℃; customized high-temperature resistant version: -30℃-200℃. |

| Control Type | Mainly stainless steel electric/pneumatic actuator control. Achieves automatic control via 4-20mA/0-10V input signal, with non-holding feature for automatic reset after power failure. Compatible with manual control for mode switching. |

| Surface Treatment | Valve body: polished finish (standard precision Ra≤0.8μm); customized hygienic-grade versions (for pharmaceutical/food industries): Ra≤0.3μm, ensuring no medium residue dead ends and compliance with hygiene standards. |

| Sealing Material | Mainstream: PTFE (polytetrafluoroethylene); optional materials: TFM, PTFE+carbon fiber, PEEK. Gasket seals mostly meet FDA 177.2600 standard, suitable for hygienic working conditions. |

| Valve Body Material | Mainly 304 stainless steel (1.4301), 316L stainless steel (1.4404); high-end hygienic scenarios (e.g., biopharmaceuticals): ASME BPE 316L (1.4435) for higher purity and corrosion resistance requirements. |

| Cleaning Compatibility | Features non-retention flow channel design, supporting CIP (Clean-in-Place) and SIP (Sterilize-in-Place) with high-temperature steam cleaning. Complies with 3-A and FDA hygiene certifications, no medium residue dead ends, suitable for high-cleanliness standards in food, pharmaceutical, and cosmetic industries. |

Features

Features a three-piece body design that allows easy disassembly and maintenance without removing the entire valve from the tank.

Pneumatic actuation provides fast, precise, and automated opening and closing, improving process efficiency and operational safety.

Constructed from high-grade stainless steel with polished internal surfaces, ensuring excellent corrosion resistance and compliance with sanitary standards.

Tank bottom installation enables complete drainage by gravity, minimizing residue and preventing cross-contamination during production.

Reliable sealing mechanism ensures leak-free performance, supporting repeated cleaning cycles and maintaining consistent hygienic operation in process lines

Application

Sanitary Stainless Steel Three-piece Pneumatic Tank Bottom Valves are widely used in dairy and beverage industries for emptying milk, juice, or other liquid products from storage or mixing tanks. They are also applied in pharmaceutical and biotechnology production, where automated, hygienic discharge of sterile liquids or intermediates is critical. Additionally, these valves are suitable for food processing and cosmetic manufacturing, providing reliable tank drainage, easy cleaning, and integration into fully automated production lines to maintain product quality and process hygiene