| Availability: | |

|---|---|

| Quantity: | |

JN-DPHV-23 1008-BJ

JONENG

8481804090

Stainless Steel Sanitary Manual Butterfly Ball Valve With Lever Handle

The stainless steel sanitary manual butterfly ball valve is designed to provide efficient and reliable fluid control solutions. The valve combines the advantages of butterfly valves and ball valves, has the characteristics of low fluid resistance and rapid opening and closing, and can maintain  stability in occasions where frequent switching is required. The manual operation mode enables it to accurately control the flow and meet the needs of different pipelines. Made of stainless steel, it has good corrosion resistance, high temperature resistance and hygiene, ensuring compliance with the strict hygiene requirements of the industry and avoiding pollution. This design aims to improve the safety of the pipeline system, fluid delivery efficiency and operation convenience, while extending the service life of the equipment.

stability in occasions where frequent switching is required. The manual operation mode enables it to accurately control the flow and meet the needs of different pipelines. Made of stainless steel, it has good corrosion resistance, high temperature resistance and hygiene, ensuring compliance with the strict hygiene requirements of the industry and avoiding pollution. This design aims to improve the safety of the pipeline system, fluid delivery efficiency and operation convenience, while extending the service life of the equipment.

Working Principles

The working principle of the stainless steel sanitary manual butterfly ball valve combines the characteristics of butterfly valves and ball valves, and adjusts the fluid in the pipeline through manual operation. A spherical valve body is installed inside the valve, which is rotated by a handle or handwheel, and the rotation angle determines the degree of opening and closing of the valve. When the handle is operated, the spherical valve body rotates in the valve seat to allow the fluid to flow or close. Unlike traditional butterfly valves, the manual butterfly ball valve provides better sealing and control through the precise adjustment of the spherical valve body, reducing fluid resistance. During operation, the valve opens or closes quickly and smoothly, and can accurately adjust the flow rate. It is suitable for pipeline systems that require fast switching or precise control.

The options of the stainless steel sanitary manual butterfly ball valve include:

Connection method: such as clamp connection, threaded connection, flange connection, etc.

Sealing material: such as EPDM, silicone, PTFE, etc., selected according to fluid requirements.

Operation method: handle operation, handwheel operation, etc.

Valve body material: 304 or 316L stainless steel can be selected.

Specifications: Different pipe diameters can be selected according to the pipe size.

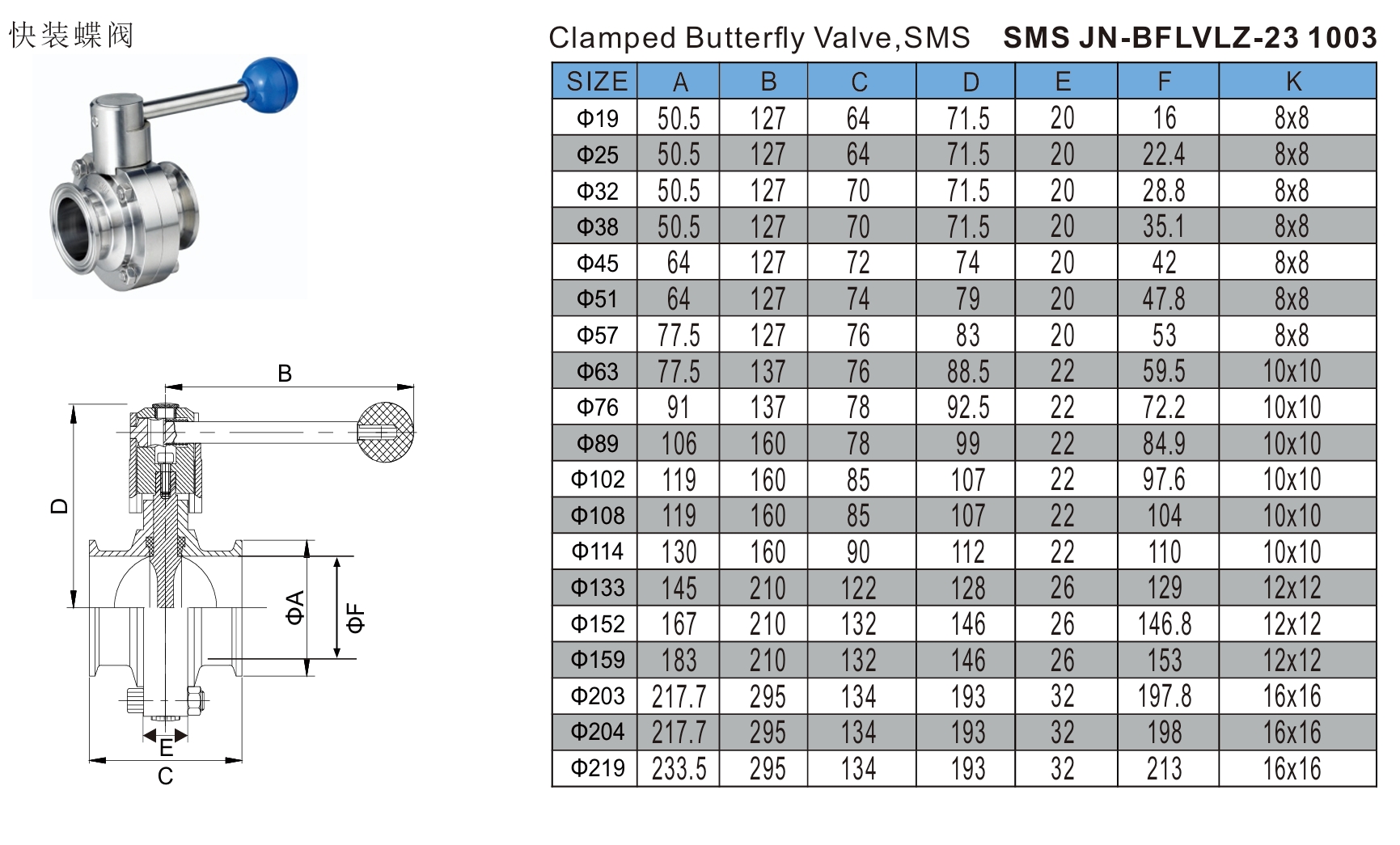

Specification Chart

Max. working pressure | 150 PSI |

Temperature range | -20° ~ +150°C or higher upon request |

Sizes available | 1/2" to 4" |

| End connection | Tri-Clamp, Butt-Weld, Flange, Threaded |

Body material | Stainless Steel 316L |

Ball material | Stainless Steel 316L |

Seal material | FDA Approved EPDM, Silicone, Viton |

Actuator Options | Manual, Pneumatic |

Surface Finish | Ra ≤ 0.8μm (Standard), Ra |

Flow Control | Linear |

Features

● The stainless steel sanitary manual butterfly ball valve adopts a double eccentric structure, and the rotation center of the butterfly plate is offset from the center of the valve body, which reduces the friction of the sealing surface and avoids the seal wear caused by frequent opening and closing of traditional butterfly valves.

● The inner cavity and butterfly plate of the stainless steel sanitary manual butterfly ball valve are electrolytically polished or mechanically mirror polished, with a surface roughness of ≤0.4μm, which is much higher than the 0.8μm standard of conventional sanitary valves.

● The sealing ring of the stainless steel sanitary manual butterfly ball valve adopts PTFE embedded in a stainless steel skeleton, which not only maintains the chemical inertness of PTFE, but also enhances the anti-deformation ability.

● The stainless steel sanitary manual butterfly ball valve body adopts a sterile grade quick-release clamp, which can be disassembled without tools, in accordance with DIN 11851 or SMS 1145 standards.

● The stainless steel sanitary manual butterfly ball valve stem adopts self-lubricating bearings or ceramic bearings, with extremely low friction coefficient, and can be easily operated even in high-viscosity media (such as syrups and colloids).

● The flow channel of the stainless steel sanitary manual butterfly ball valve adopts a full-bore design, and the gap between the edge of the butterfly plate and the inner wall of the valve body is ≤1mm, which is much lower than the conventional 3mm standard, and there is almost no residue.

Application

Stainless steel sanitary manual butterfly ball valves are widely used in the following industries: Food processing industry: used to control the flow of liquids such as beverages, juices, and dairy products to ensure product hygiene and precise flow regulation. Beverage industry: Control fluid flow in beverage production to ensure efficient production in a sterile environment. Pharmaceutical industry: Used for precise flow control of drugs and chemicals to ensure a pollution-free production environment. Cosmetics industry: Control the flow of cosmetic raw materials to ensure product quality and safety. Water treatment industry: Used for flow regulation and pipeline system cut-off control during water treatment. Dairy industry: Used for fluid control in dairy production to ensure compliance with hygiene requirements.

Working Principles

The working principle of the stainless steel sanitary manual butterfly ball valve combines the characteristics of butterfly valves and ball valves, and adjusts the fluid in the pipeline through manual operation. A spherical valve body is installed inside the valve, which is rotated by a handle or handwheel, and the rotation angle determines the degree of opening and closing of the valve. When the handle is operated, the spherical valve body rotates in the valve seat to allow the fluid to flow or close. Unlike traditional butterfly valves, the manual butterfly ball valve provides better sealing and control through the precise adjustment of the spherical valve body, reducing fluid resistance. During operation, the valve opens or closes quickly and smoothly, and can accurately adjust the flow rate. It is suitable for pipeline systems that require fast switching or precise control.

The options of the stainless steel sanitary manual butterfly ball valve include:

Connection method: such as clamp connection, threaded connection, flange connection, etc.

Sealing material: such as EPDM, silicone, PTFE, etc., selected according to fluid requirements.

Operation method: handle operation, handwheel operation, etc.

Valve body material: 304 or 316L stainless steel can be selected.

Specifications: Different pipe diameters can be selected according to the pipe size.

Specification Chart

Max. working pressure | 150 PSI |

Temperature range | -20° ~ +150°C or higher upon request |

Sizes available | 1/2" to 4" |

End connection | Tri-Clamp, Butt-Weld, Flange, Threaded |

Body material | Stainless Steel 316L |

Ball material | Stainless Steel 316L |

Seal material | FDA Approved EPDM, Silicone, Viton |

Actuator Options | Manual, Pneumatic |

Surface Finish | Ra ≤ 0.8μm (Standard), Ra |

Flow Control | Linear |

Features

● The stainless steel sanitary manual butterfly ball valve adopts a double eccentric structure, and the rotation center of the butterfly plate is offset from the center of the valve body, which reduces the friction of the sealing surface and avoids the seal wear caused by frequent opening and closing of traditional butterfly valves.

● The inner cavity and butterfly plate of the stainless steel sanitary manual butterfly ball valve are electrolytically polished or mechanically mirror polished, with a surface roughness of ≤0.4μm, which is much higher than the 0.8μm standard of conventional sanitary valves.

● The sealing ring of the stainless steel sanitary manual butterfly ball valve adopts PTFE embedded in a stainless steel skeleton, which not only maintains the chemical inertness of PTFE, but also enhances the anti-deformation ability.

● The stainless steel sanitary manual butterfly ball valve body adopts a sterile grade quick-release clamp, which can be disassembled without tools, in accordance with DIN 11851 or SMS 1145 standards.

● The stainless steel sanitary manual butterfly ball valve stem adopts self-lubricating bearings or ceramic bearings, with extremely low friction coefficient, and can be easily operated even in high-viscosity media (such as syrups and colloids).

● The flow channel of the stainless steel sanitary manual butterfly ball valve adopts a full-bore design, and the gap between the edge of the butterfly plate and the inner wall of the valve body is ≤1mm, which is much lower than the conventional 3mm standard, and there is almost no residue.

Application

Stainless steel sanitary manual butterfly ball valves are widely used in the following industries: Food processing industry: used to control the flow of liquids such as beverages, juices, and dairy products to ensure product hygiene and precise flow regulation. Beverage industry: Control fluid flow in beverage production to ensure efficient production in a sterile environment. Pharmaceutical industry: Used for precise flow control of drugs and chemicals to ensure a pollution-free production environment. Cosmetics industry: Control the flow of cosmetic raw materials to ensure product quality and safety. Water treatment industry: Used for flow regulation and pipeline system cut-off control during water treatment. Dairy industry: Used for fluid control in dairy production to ensure compliance with hygiene requirements.