| Availability: | |

|---|---|

| Quantity: | |

JN-FDV2004

JONENG

8481804090

Stainless Steel Food Grade Clamped Cylindrical Base Pneumatic Reversing Valve

The stainless steel sanitary cylindrical base pneumatic reversing valve is designed to provide precise and fast fluid control in high-demand pipeline systems. Its unique cylindrical base design not only improves the stability of the valve body, but also ensures rapid switching of fluid flow by optimizing the pneumatic drive mechanism, avoiding any retention or cross contamination. Especially suitable for environments where the direction of the fluid needs to be frequently switched, such as food processing and pharmaceutical industries, this valve can effectively prevent contamination caused by improper flow direction in the system, maintain high hygiene standards in the fluid delivery process, and ensure product quality and aseptic state of the production process.

Working Principles

The working principle of the stainless steel sanitary cylindrical base pneumatic reversing valve is based on pneumatically driven reversing control. When the pneumatic valve receives a control signal, the air source pushes the valve core to move through the air inlet of the valve body, thereby changing the flow direction of the fluid. After receiving the air pressure signal, the pneumatic actuator drives the valve core in the cylindrical base to move. According to the position of the valve core, the fluid flows through different outlet ports to achieve the switching of the flow direction. The return of the valve core is completed by releasing the air pressure or reversing the air source to ensure smooth switching of the fluid flow direction.

The options of the stainless steel sanitary cylindrical base pneumatic reversing valve include:

Material selection: stainless steel 304, 316, 316L, etc.

Control mode: single-acting or double-acting pneumatic control.

Interface type: threaded connection, clamp connection or welding connection.

Valve body specifications: 2/2 position, 3/2 position, 5/2 position, 5/3 position and other different specifications.

Sealing material: rubber, PTFE, fluororubber and other different material options.

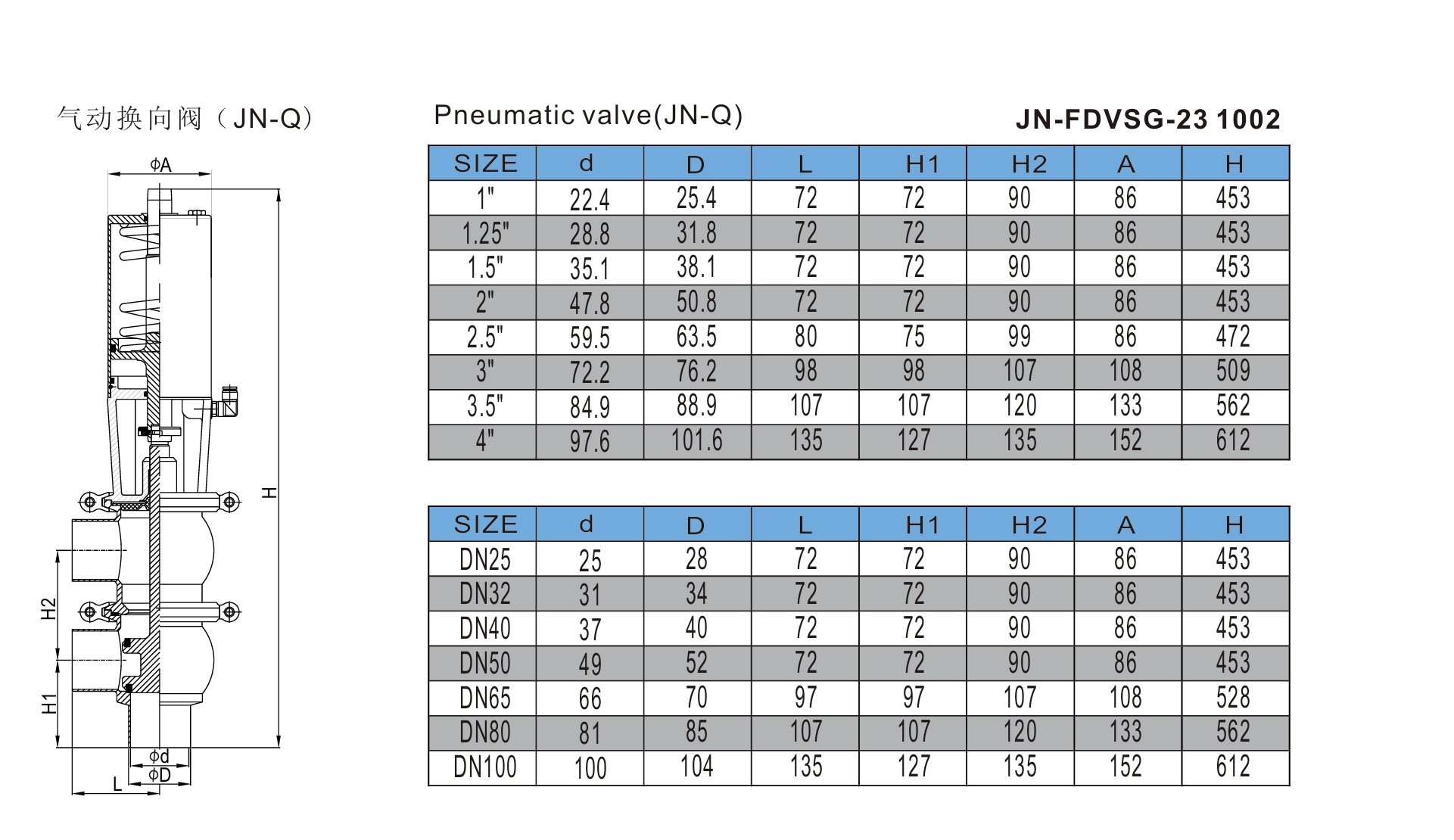

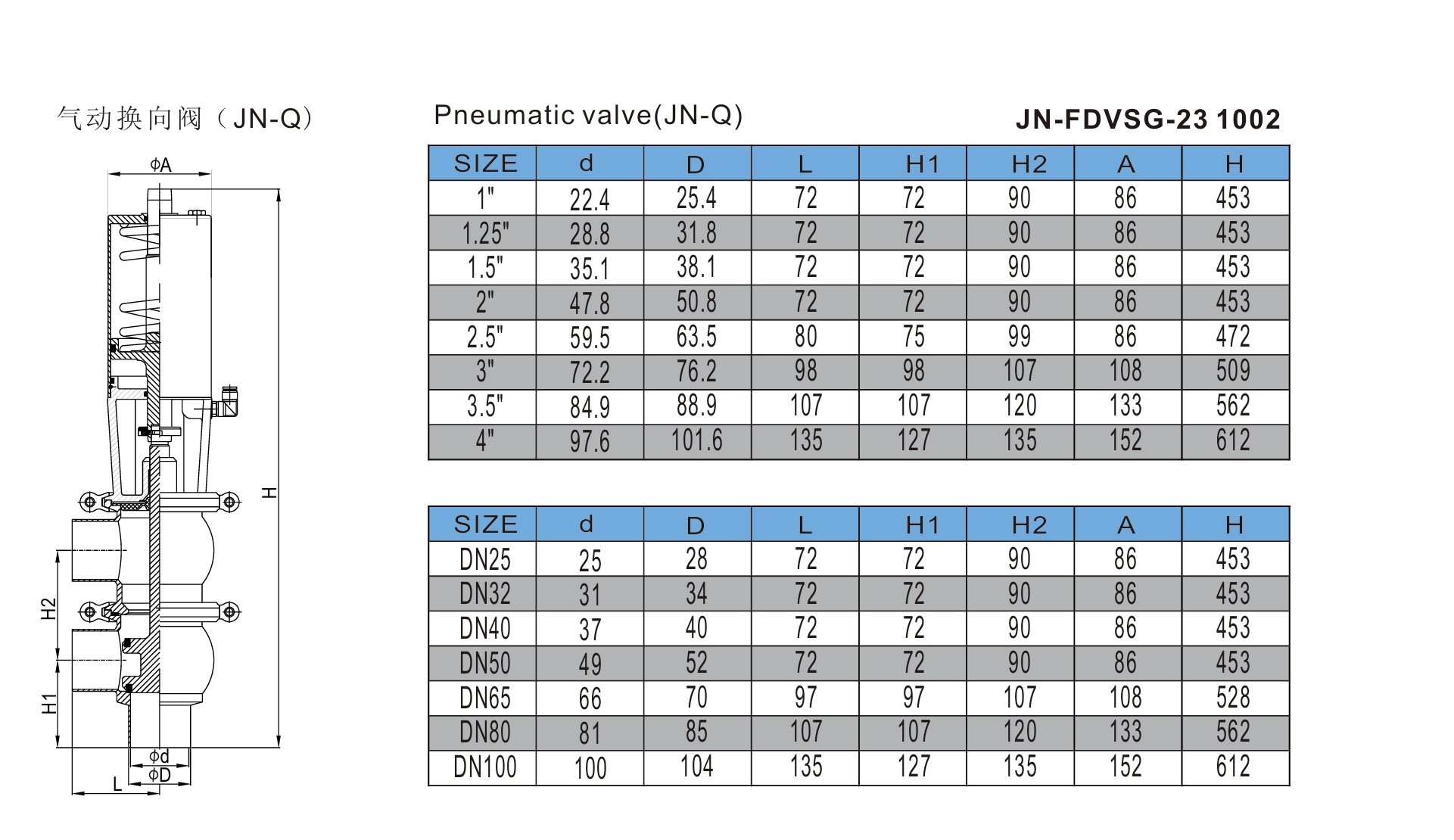

Specification Chart

Working Temperature | -10 ° to 120 ° |

Pressure | 10bar |

Work operate | Manual, pneumatic type |

Gasket | EPDM, Silicone, Viton according to FDA 177.2600 |

Valve body type | LL, LT, TL and TT type |

Connection mode | Clamped, welded, male threaded, female threaded, flange end, union connection |

Specification | 1/2"-4", DN15-DN100 |

Material quality | SUS304, SUS316L |

Surface | Mirror polished,Matte polished or sand blasting type |

inner surface | Ra 0.4um to meet the requirement of food industries |

| Standard | SMS,DIN,3A,ISO,RJT and so on |

| Required compressed air | 4-8Bar |

| Connection of compressed air | G 1/8’’ |

| Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose ) |

Normally closed valve is the standard version.The valve can be changed to normally open by simply reversing the position of the pneumatic actuator. | |

External position sensors is available if needed | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

C top control unit is available if needed. | |

Features

● The stainless steel sanitary cylindrical base pneumatic reversing valve has a self-adjusting pneumatic drive function, which can automatically adjust the speed and force of the valve core movement according to the system air pressure to ensure the accuracy of fluid control.

● The stainless steel sanitary cylindrical base pneumatic reversing valve uses specially treated low-friction materials, such as PTFE coating, which reduces the contact friction with the valve seat and extends the service life of the valve body.

● The stainless steel sanitary cylindrical base pneumatic reversing valve supports multi-angle installation, whether vertical, horizontal or other complex angles, it can maintain normal operation.

● The stainless steel sanitary cylindrical base pneumatic reversing valve is designed with an independent sealing system inside, including secondary sealing rings and auxiliary sealing systems, which further improves the sealing performance.

● The stainless steel sanitary cylindrical base pneumatic reversing valve has a built-in pneumatic positioner, which can accurately control the positioning of the valve core to ensure that each switch reaches the set accurate position.

● The stainless steel sanitary cylindrical base pneumatic reversing valve uses a high-precision pneumatic actuator combined with a special valve core. The valve core responds very quickly and can complete the flow direction switching in a very short time.

Application

Stainless steel sanitary cylindrical base pneumatic reversing valves are widely used in the following industries: Food processing: used to control the flow direction of fluids in production lines to ensure hygiene and safety. Pharmaceutical industry: Ensure accurate control and direction switching of fluids in a sterile environment. Bioengineering: Used for switching and controlling the flow direction of fluids in cell culture and reactors. Chemical industry: Ensure accurate flow direction and system safety when handling highly corrosive fluids. Beverage industry: Control the flow direction of raw materials in the beverage production process to maintain hygiene requirements. Water treatment industry: Control the direction of water flow to ensure smooth flow of fluids during water treatment.

Working Principles

The working principle of the stainless steel sanitary cylindrical base pneumatic reversing valve is based on pneumatically driven reversing control. When the pneumatic valve receives a control signal, the air source pushes the valve core to move through the air inlet of the valve body, thereby changing the flow direction of the fluid. After receiving the air pressure signal, the pneumatic actuator drives the valve core in the cylindrical base to move. According to the position of the valve core, the fluid flows through different outlet ports to achieve the switching of the flow direction. The return of the valve core is completed by releasing the air pressure or reversing the air source to ensure smooth switching of the fluid flow direction.

The options of the stainless steel sanitary cylindrical base pneumatic reversing valve include:

Material selection: stainless steel 304, 316, 316L, etc.

Control mode: single-acting or double-acting pneumatic control.

Interface type: threaded connection, clamp connection or welding connection.

Valve body specifications: 2/2 position, 3/2 position, 5/2 position, 5/3 position and other different specifications.

Sealing material: rubber, PTFE, fluororubber and other different material options.

Specification Chart

Working Temperature | -10 ° to 120 ° |

Pressure | 10bar |

Work operate | Manual, pneumatic type |

Gasket | EPDM, Silicone, Viton according to FDA 177.2600 |

Valve body type | LL, LT, TL and TT type |

Connection mode | Clamped, welded, male threaded, female threaded, flange end, union connection |

Specification | 1/2"-4", DN15-DN100 |

Material quality | SUS304, SUS316L |

Surface | Mirror polished,Matte polished or sand blasting type |

inner surface | Ra 0.4um to meet the requirement of food industries |

| Standard | SMS,DIN,3A,ISO,RJT and so on |

| Required compressed air | 4-8Bar |

| Connection of compressed air | G 1/8’’ |

| Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose ) |

Normally closed valve is the standard version.The valve can be changed to normally open by simply reversing the position of the pneumatic actuator. | |

External position sensors is available if needed | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

C top control unit is available if needed. | |

Features

● The stainless steel sanitary cylindrical base pneumatic reversing valve has a self-adjusting pneumatic drive function, which can automatically adjust the speed and force of the valve core movement according to the system air pressure to ensure the accuracy of fluid control.

● The stainless steel sanitary cylindrical base pneumatic reversing valve uses specially treated low-friction materials, such as PTFE coating, which reduces the contact friction with the valve seat and extends the service life of the valve body.

● The stainless steel sanitary cylindrical base pneumatic reversing valve supports multi-angle installation, whether vertical, horizontal or other complex angles, it can maintain normal operation.

● The stainless steel sanitary cylindrical base pneumatic reversing valve is designed with an independent sealing system inside, including secondary sealing rings and auxiliary sealing systems, which further improves the sealing performance.

● The stainless steel sanitary cylindrical base pneumatic reversing valve has a built-in pneumatic positioner, which can accurately control the positioning of the valve core to ensure that each switch reaches the set accurate position.

● The stainless steel sanitary cylindrical base pneumatic reversing valve uses a high-precision pneumatic actuator combined with a special valve core. The valve core responds very quickly and can complete the flow direction switching in a very short time.

Application

Stainless steel sanitary cylindrical base pneumatic reversing valves are widely used in the following industries: Food processing: used to control the flow direction of fluids in production lines to ensure hygiene and safety. Pharmaceutical industry: Ensure accurate control and direction switching of fluids in a sterile environment. Bioengineering: Used for switching and controlling the flow direction of fluids in cell culture and reactors. Chemical industry: Ensure accurate flow direction and system safety when handling highly corrosive fluids. Beverage industry: Control the flow direction of raw materials in the beverage production process to maintain hygiene requirements. Water treatment industry: Control the direction of water flow to ensure smooth flow of fluids during water treatment.