| Availability: | |

|---|---|

| Quantity: | |

JN-SV2008

JONENG

8481804090

Stainless Steel Sanitary DIN Clamped Manual Cut Off Valve

The stainless steel sanitary manual stop valve is designed to ensure precise control of the flow of fluids in high-demand industrial environments while meeting strict hygiene standards. By adopting manual operation, users can accurately close or adjust the fluid in the pipeline system to avoid safety risks caused by automatic system failures. Its unique structure and material make it resistant to corrosion, high temperature, and maintain long-term stable operation. The sealing performance in the design is particularly important, which can effectively prevent fluid leakage or contamination, ensure that the fluid is not contaminated by the outside during the production process of food, pharmaceutical and other industries, and maintain high cleanliness and hygiene standards.

Working Principles

The working principle of the stainless steel sanitary manual stop valve is to operate the valve disc by manually rotating the valve stem to control the flow of fluid in the pipeline. First, when the valve stem is manually rotated, the valve disc is driven up and down through the connection between the valve stem and the valve disc, gradually opening or closing the fluid channel. When the valve stem is rotated clockwise, the valve disc is closed downward, and the fluid flow is completely cut off; conversely, when the valve stem is rotated counterclockwise, the valve disc rises, the fluid channel is opened, and the fluid is allowed to flow. Using a stainless steel sanitary manual stop valve can increase the reliability and safety of operation, especially for pipeline systems with precise control requirements.

The options for stainless steel sanitary manual stop valves include:

Material: 304 stainless steel, 316L stainless steel.

Connection method: threaded connection, flange connection, welding connection.

Sealing material: PTFE, rubber, EPDM.

Size: Select different sizes according to pipeline specifications.

Operation method: handle rotation, gear transmission.

Surface treatment: mirror polishing, sand blasting.

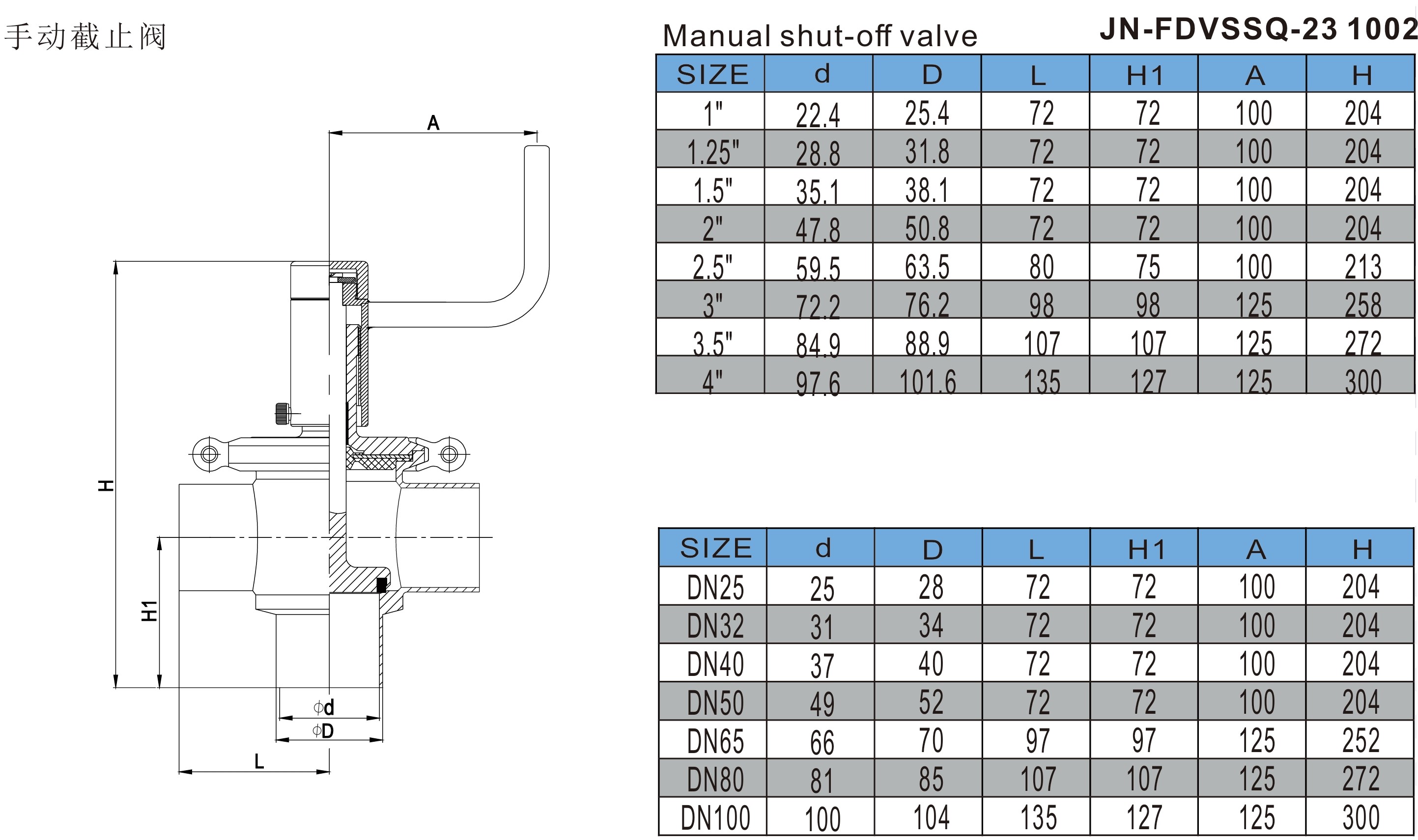

Specification Chart

Working Temperature | -10 ° to 120 ° |

Pressure | 10bar |

Work operate | Manual, pneumatic type |

Gasket | EPDM, Silicone, Viton according to FDA 177.2600 |

Valve body type | LL, LT, TL and TT type |

Connection mode | Clamped, welded, male threaded, female threaded, flange end, union connection |

Specification | 1/2"-4", DN15-DN100 |

Material quality | SUS304, SUS316L |

Surface | Mirror polished,Matte polished or sand blasting type |

inner surface | Ra 0.4um to meet the requirement of food industries |

| Standard | SMS,DIN,3A,ISO,RJT and so on |

| Required compressed air | 4-8Bar |

| Connection of compressed air | G 1/8’’ |

| Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose ) |

Normally closed valve is the standard version.The valve can be changed to normally open by simply reversing the position of the pneumatic actuator. | |

External position sensors is available if needed | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

C top control unit is available if needed. | |

Features

● The stainless steel sanitary manual stop valve adopts a double seal design, including two inner and outer sealing surfaces. The inner seal provides fluid barrier, and the outer seal ensures no leakage when the valve is closed.

● The valve disc and valve seat of the stainless steel sanitary manual stop valve adopt a special anti-wear coating, which reduces wear during frequent operation and extends the service life of the valve.

● In some special designs of stainless steel sanitary manual stop valves, the manual stop valve is equipped with an automatic pressure regulating device, which can automatically adjust the pressure change within a certain range.

● The design of stainless steel sanitary manual stop valve includes a quick pressure relief valve, which can quickly release the pressure in the valve to avoid pressure shock when closing the valve.

● The internal high-temperature cooling design of the stainless steel sanitary manual stop valve can maintain the stability of the valve body in a high temperature environment and avoid valve deformation caused by high temperature.

● The internal design of the stainless steel sanitary manual stop valve is streamlined, which minimizes the resistance of the fluid inside the valve and reduces the energy loss in the fluid flow.

Application

Stainless steel sanitary manual stop valves are widely used in the following industries: Food processing industry: ensure fluid flow safety and meet high hygiene standards. Pharmaceutical industry: control fluid flow in the drug manufacturing process to avoid contamination. Beverage production: accurately control pipeline fluid flow during beverage production. Chemical industry: suitable for chemical delivery systems to ensure high sealing and safety. Bioengineering: used in bioreactor systems to ensure precise control of fluid flow. Water treatment industry: regulate fluid flow in water treatment equipment to ensure water quality safety.

Working Principles

The working principle of the stainless steel sanitary manual stop valve is to operate the valve disc by manually rotating the valve stem to control the flow of fluid in the pipeline. First, when the valve stem is manually rotated, the valve disc is driven up and down through the connection between the valve stem and the valve disc, gradually opening or closing the fluid channel. When the valve stem is rotated clockwise, the valve disc is closed downward, and the fluid flow is completely cut off; conversely, when the valve stem is rotated counterclockwise, the valve disc rises, the fluid channel is opened, and the fluid is allowed to flow. Using a stainless steel sanitary manual stop valve can increase the reliability and safety of operation, especially for pipeline systems with precise control requirements.

The options for stainless steel sanitary manual stop valves include:

Material: 304 stainless steel, 316L stainless steel.

Connection method: threaded connection, flange connection, welding connection.

Sealing material: PTFE, rubber, EPDM.

Size: Select different sizes according to pipeline specifications.

Operation method: handle rotation, gear transmission.

Surface treatment: mirror polishing, sand blasting.

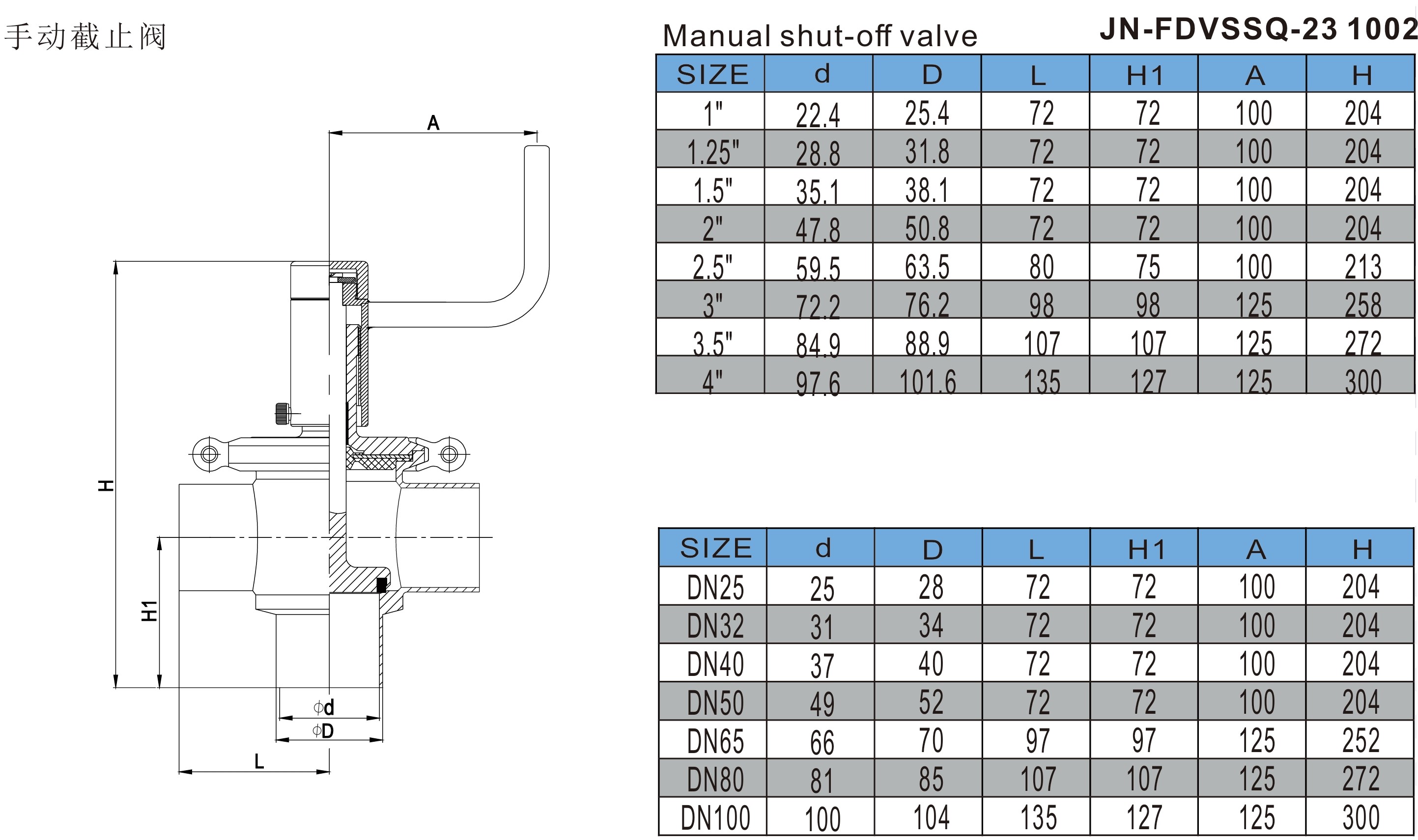

Specification Chart

Working Temperature | -10 ° to 120 ° |

Pressure | 10bar |

Work operate | Manual, pneumatic type |

Gasket | EPDM, Silicone, Viton according to FDA 177.2600 |

Valve body type | LL, LT, TL and TT type |

Connection mode | Clamped, welded, male threaded, female threaded, flange end, union connection |

Specification | 1/2"-4", DN15-DN100 |

Material quality | SUS304, SUS316L |

Surface | Mirror polished,Matte polished or sand blasting type |

inner surface | Ra 0.4um to meet the requirement of food industries |

| Standard | SMS,DIN,3A,ISO,RJT and so on |

| Required compressed air | 4-8Bar |

| Connection of compressed air | G 1/8’’ |

| Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose ) |

Normally closed valve is the standard version.The valve can be changed to normally open by simply reversing the position of the pneumatic actuator. | |

External position sensors is available if needed | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

C top control unit is available if needed. | |

Features

● The stainless steel sanitary manual stop valve adopts a double seal design, including two inner and outer sealing surfaces. The inner seal provides fluid barrier, and the outer seal ensures no leakage when the valve is closed.

● The valve disc and valve seat of the stainless steel sanitary manual stop valve adopt a special anti-wear coating, which reduces wear during frequent operation and extends the service life of the valve.

● In some special designs of stainless steel sanitary manual stop valves, the manual stop valve is equipped with an automatic pressure regulating device, which can automatically adjust the pressure change within a certain range.

● The design of stainless steel sanitary manual stop valve includes a quick pressure relief valve, which can quickly release the pressure in the valve to avoid pressure shock when closing the valve.

● The internal high-temperature cooling design of the stainless steel sanitary manual stop valve can maintain the stability of the valve body in a high temperature environment and avoid valve deformation caused by high temperature.

● The internal design of the stainless steel sanitary manual stop valve is streamlined, which minimizes the resistance of the fluid inside the valve and reduces the energy loss in the fluid flow.

Application

Stainless steel sanitary manual stop valves are widely used in the following industries: Food processing industry: ensure fluid flow safety and meet high hygiene standards. Pharmaceutical industry: control fluid flow in the drug manufacturing process to avoid contamination. Beverage production: accurately control pipeline fluid flow during beverage production. Chemical industry: suitable for chemical delivery systems to ensure high sealing and safety. Bioengineering: used in bioreactor systems to ensure precise control of fluid flow. Water treatment industry: regulate fluid flow in water treatment equipment to ensure water quality safety.