| Availability: | |

|---|---|

| Quantity: | |

JN-FDV2010

JONENG

8481804090

Stainless Steel Sanitary Welded Pneumatic Stop Valve For Pharmaceutical Use

The stainless steel sanitary welded pneumatic stop valve is designed to provide precise, reliable and hygienic fluid control, especially for industries that require strict hygiene standards, such as food, pharmaceutical and biotechnology. Its pneumatic drive method ensures efficient and fast switching operations in automated production lines, while reducing potential leakage and contamination risks through welding interfaces. The design of the valve body eliminates the possible health hazards at traditional threaded joints and ensures sterility during fluid delivery. The use of high-quality stainless steel makes it corrosion-resistant and high-temperature resistant, and adaptable to different production environments. In addition, the pneumatic control system can also achieve precise flow regulation according to demand, providing stable guarantee for complex process flows, thereby achieving more efficient production, improving product quality, and meeting industry standards such as GMP or FDA.

Working Principles

The working principle of the stainless steel sanitary welded pneumatic stop valve is based on a pneumatic drive system to accurately adjust the fluid flow. First, the air source provides power through the pneumatic actuator to push the valve core or valve disc of the valve to open or close. The pneumatic actuator is usually driven by the air source control signal and cooperates with the fluid path in the valve body to control the flow state of the fluid. When the valve is in the open state, the fluid flows freely; when the valve is closed, the fluid is effectively blocked to achieve the purpose of flow control and leakage prevention.

The options of the stainless steel sanitary welded pneumatic stop valve include:

Actuator type: double-acting or single-acting pneumatic actuator.

Sealing material: corrosion-resistant materials such as EPDM and PTFE.

Valve size: different sizes can be selected according to the pipeline specifications.

Control mode: switch type or regulation type.

Connection method: welding, quick-install and other interface methods.

Valve seat type: single-seat or double-seat valve seat.

Air source pressure: can be customized to adapt to different air pressures as needed.

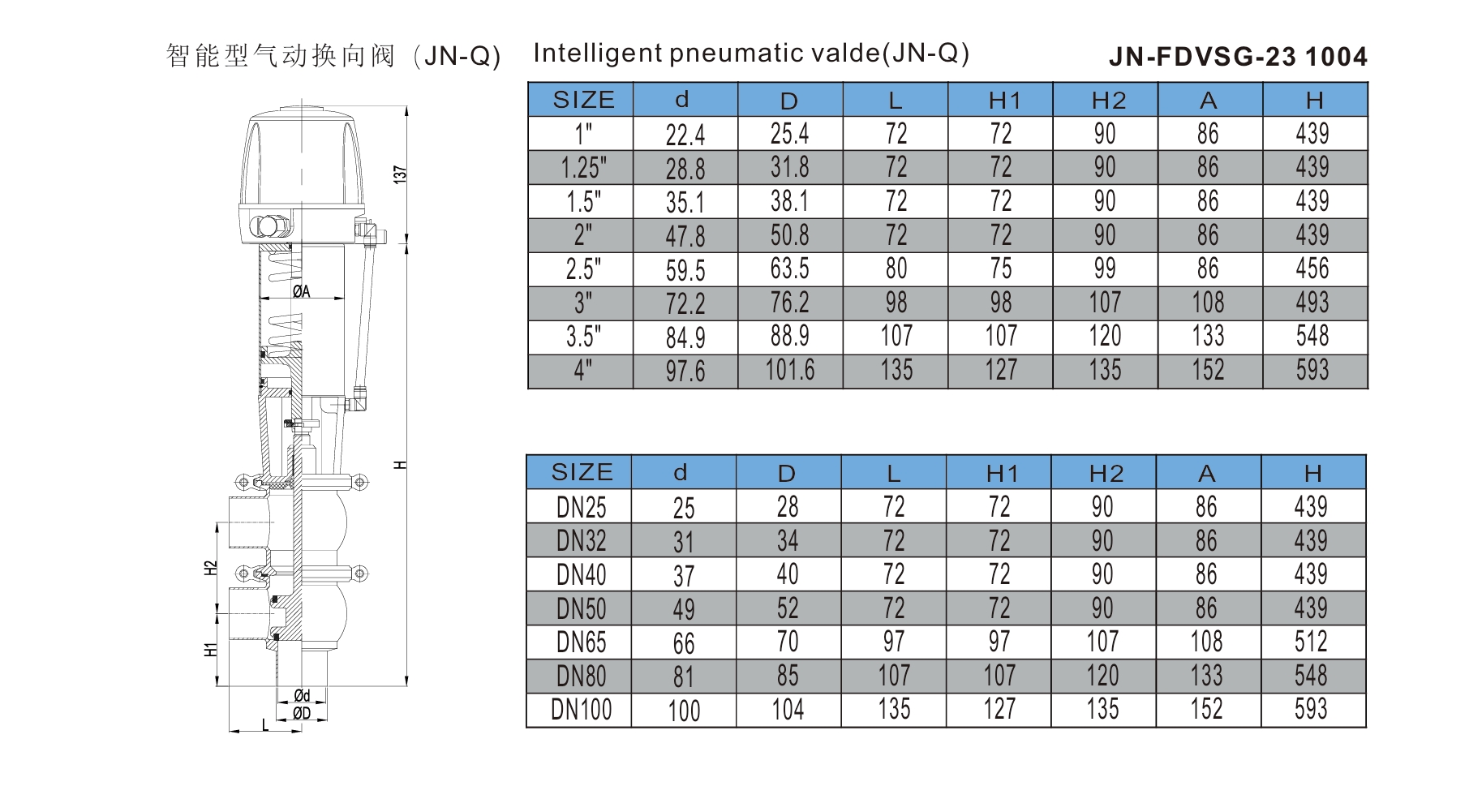

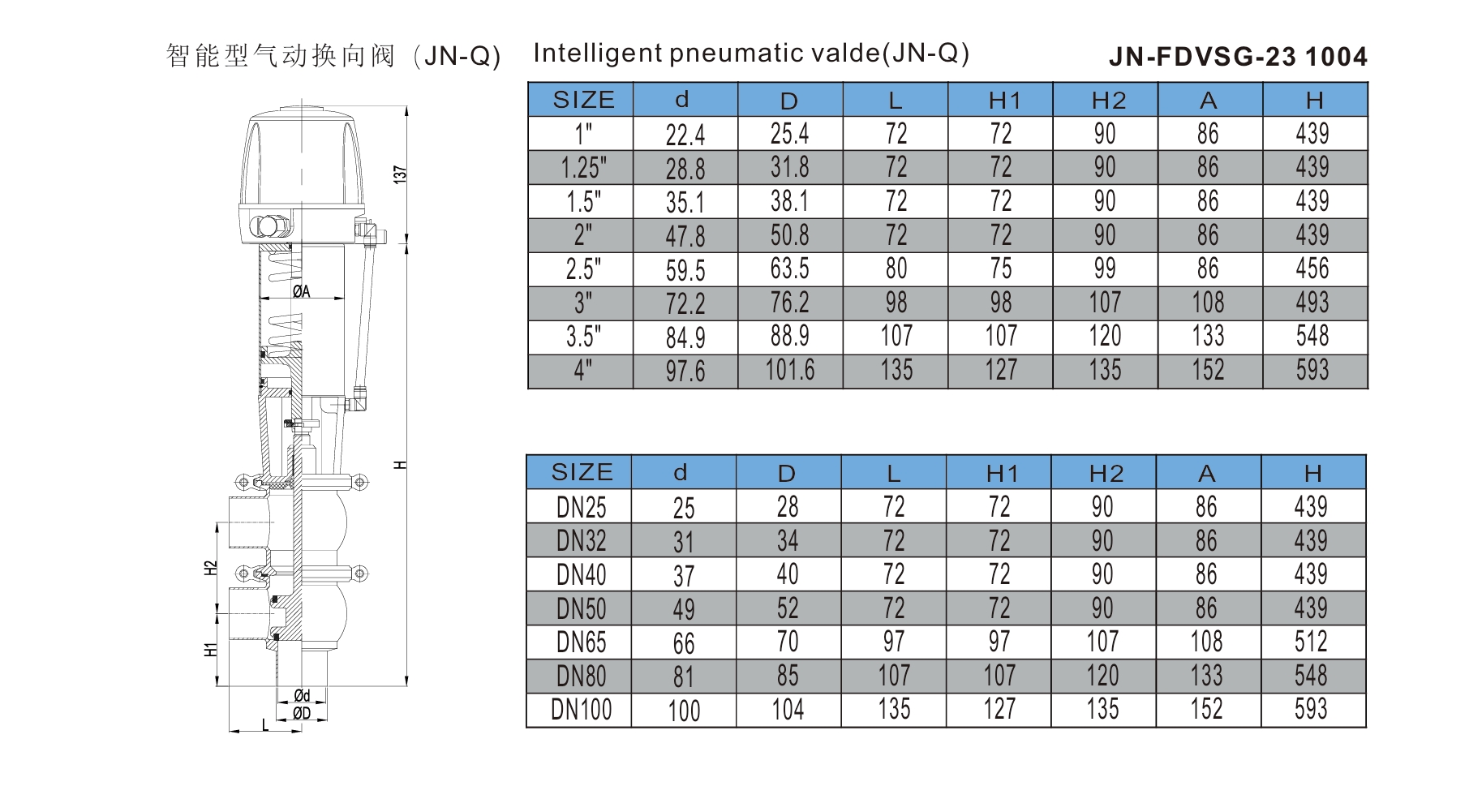

Specification Chart

Working Temperature | -10 ° to 120 ° |

Pressure | 10bar |

Work operate | Manual, pneumatic type |

Gasket | EPDM, Silicone, Viton according to FDA 177.2600 |

Valve body type | LL, LT, TL and TT type |

Connection mode | Clamped, welded, male threaded, female threaded, flange end, union connection |

Specification | 1/2"-4", DN15-DN100 |

Material quality | SUS304, SUS316L |

Surface | Mirror polished,Matte polished or sand blasting type |

inner surface | Ra 0.4um to meet the requirement of food industries |

| Standard | SMS,DIN,3A,ISO,RJT and so on |

| Required compressed air | 4-8Bar |

| Connection of compressed air | G 1/8’’ |

| Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose ) |

Normally closed valve is the standard version.The valve can be changed to normally open by simply reversing the position of the pneumatic actuator. | |

External position sensors is available if needed | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

C top control unit is available if needed. | |

Features

● The stainless steel sanitary welded pneumatic stop valve adopts a modular design. The valve body and other components can be easily disassembled for thorough cleaning, which meets the hygiene requirements.

● The stainless steel sanitary welded pneumatic stop valve is designed with a special pressure regulation function, which can automatically adjust in the event of sudden pressure fluctuations to avoid system damage.

● The stainless steel sanitary welded pneumatic stop valve adopts high-grade stainless steel materials and special surface treatment technology to improve the valve's resistance to corrosive fluids.

● The stainless steel sanitary welded pneumatic stop valve is equipped with an intelligent control module, which can automatically adjust the valve opening according to the fluid flow and pressure to ensure the best control state.

● The stainless steel sanitary welded pneumatic stop valve material has been specially treated to withstand high temperatures and pressures, and is suitable for pipelines with high-temperature fluids.

● The stainless steel sanitary welded pneumatic stop valve adopts multi-layer sealing technology to ensure that the valve can still effectively prevent fluid leakage in extreme environments.

Application

Stainless steel sanitary welded pneumatic stop valves are widely used in the following industries: Food industry: used for automated fluid control of beverages, dairy products, etc. Pharmaceutical industry: meets GMP standards and is used in drug production processes. Bioengineering: Suitable for biological reaction systems with high cleanliness requirements. Cosmetics industry: used for raw material transportation and finished product filling processes. Brewing industry: used for wine production and filling equipment. Chemical industry: suitable for sanitary piping systems for corrosive media.

Working Principles

The working principle of the stainless steel sanitary welded pneumatic stop valve is based on a pneumatic drive system to accurately adjust the fluid flow. First, the air source provides power through the pneumatic actuator to push the valve core or valve disc of the valve to open or close. The pneumatic actuator is usually driven by the air source control signal and cooperates with the fluid path in the valve body to control the flow state of the fluid. When the valve is in the open state, the fluid flows freely; when the valve is closed, the fluid is effectively blocked to achieve the purpose of flow control and leakage prevention.

The options of the stainless steel sanitary welded pneumatic stop valve include:

Actuator type: double-acting or single-acting pneumatic actuator.

Sealing material: corrosion-resistant materials such as EPDM and PTFE.

Valve size: different sizes can be selected according to the pipeline specifications.

Control mode: switch type or regulation type.

Connection method: welding, quick-install and other interface methods.

Valve seat type: single-seat or double-seat valve seat.

Air source pressure: can be customized to adapt to different air pressures as needed.

Specification Chart

Working Temperature | -10 ° to 120 ° |

Pressure | 10bar |

Work operate | Manual, pneumatic type |

Gasket | EPDM, Silicone, Viton according to FDA 177.2600 |

Valve body type | LL, LT, TL and TT type |

Connection mode | Clamped, welded, male threaded, female threaded, flange end, union connection |

Specification | 1/2"-4", DN15-DN100 |

Material quality | SUS304, SUS316L |

Surface | Mirror polished,Matte polished or sand blasting type |

inner surface | Ra 0.4um to meet the requirement of food industries |

| Standard | SMS,DIN,3A,ISO,RJT and so on |

| Required compressed air | 4-8Bar |

| Connection of compressed air | G 1/8’’ |

| Limit switch | 6-36V, DC 2nos of NPN or PNP( to be chose ) |

Normally closed valve is the standard version.The valve can be changed to normally open by simply reversing the position of the pneumatic actuator. | |

External position sensors is available if needed | |

Manual or pneumatic actuated or electric actuated are chosen as per the different applications. | |

C top control unit is available if needed. | |

Features

● The stainless steel sanitary welded pneumatic stop valve adopts a modular design. The valve body and other components can be easily disassembled for thorough cleaning, which meets the hygiene requirements.

● The stainless steel sanitary welded pneumatic stop valve is designed with a special pressure regulation function, which can automatically adjust in the event of sudden pressure fluctuations to avoid system damage.

● The stainless steel sanitary welded pneumatic stop valve adopts high-grade stainless steel materials and special surface treatment technology to improve the valve's resistance to corrosive fluids.

● The stainless steel sanitary welded pneumatic stop valve is equipped with an intelligent control module, which can automatically adjust the valve opening according to the fluid flow and pressure to ensure the best control state.

● The stainless steel sanitary welded pneumatic stop valve material has been specially treated to withstand high temperatures and pressures, and is suitable for pipelines with high-temperature fluids.

● The stainless steel sanitary welded pneumatic stop valve adopts multi-layer sealing technology to ensure that the valve can still effectively prevent fluid leakage in extreme environments.

Application

Stainless steel sanitary welded pneumatic stop valves are widely used in the following industries: Food industry: used for automated fluid control of beverages, dairy products, etc. Pharmaceutical industry: meets GMP standards and is used in drug production processes. Bioengineering: Suitable for biological reaction systems with high cleanliness requirements. Cosmetics industry: used for raw material transportation and finished product filling processes. Brewing industry: used for wine production and filling equipment. Chemical industry: suitable for sanitary piping systems for corrosive media.